Tail gas treating method and treating system for preparing zirconium oxychloride by boiling chlorination process

A technology of boiling chlorination and tail gas treatment, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of reducing carbon monoxide concentration, high processing cost, and troublesome processing, so as to avoid emissions and avoid over-treatment , the effect of reducing cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

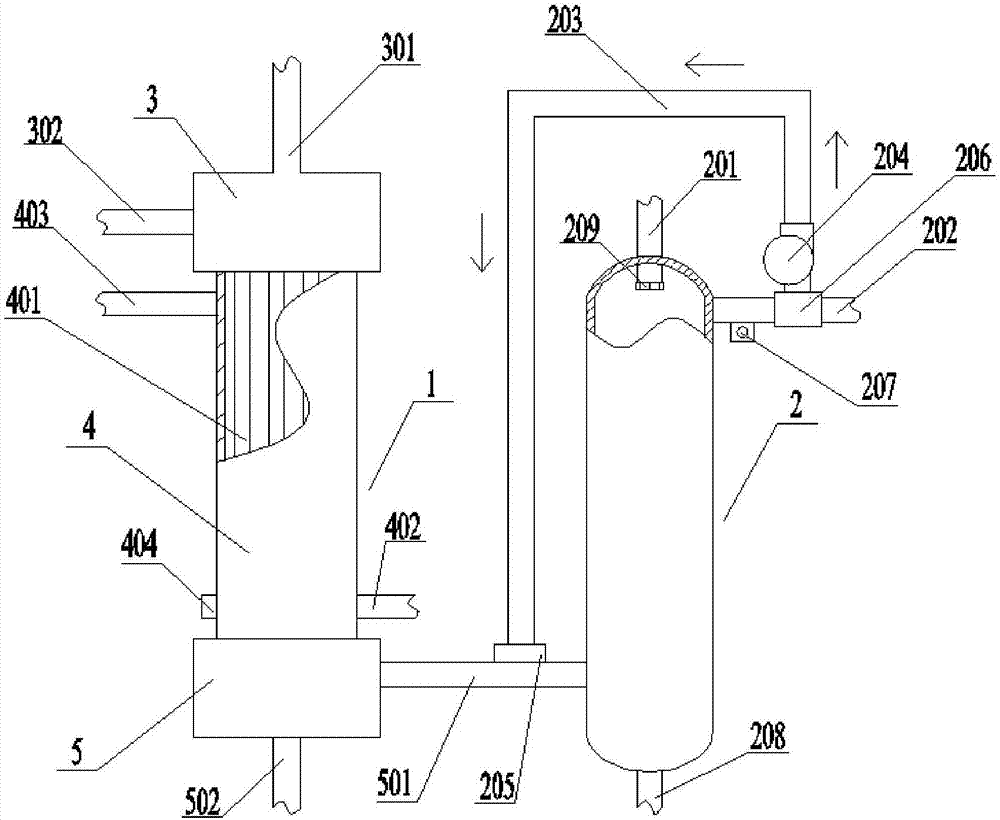

[0035] A tail gas treatment method for preparing zirconium oxychloride by boiling chlorination, comprising the following steps:

[0036] Feed the liquid absorption medium into the falling film absorber and the packed absorption tower respectively; and first pass the tail gas containing hydrogen chloride into the falling film absorber, and the liquid absorption medium absorbs the hydrogen chloride gas in the tail gas for the first time ;

[0037] After the first absorption treatment, part of the hydrogen chloride gas in the tail gas is discharged with the liquid absorption medium, and the remaining tail gas is passed into the packed absorption tower along the tail gas transmission pipe, and the hydrogen chloride gas in the tail gas is subjected to the second absorption treatment;

[0038] The remaining hydrogen chloride gas in the tail gas after the second absorption treatment is discharged with the liquid absorption medium, and the remaining tail gas is tested for hydrogen chl...

Embodiment 2

[0074] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

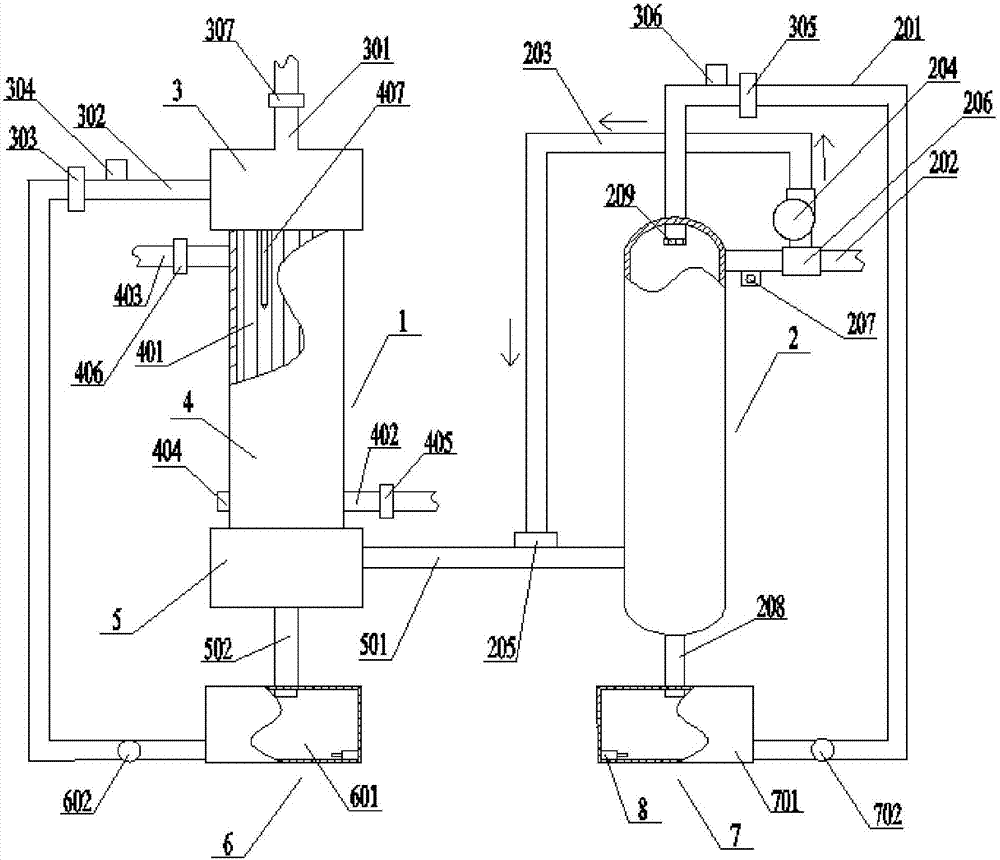

[0075] Such as image 3 , 4As shown, the tail gas treatment system for preparing zirconium oxychloride by the boiling chlorination method described in this embodiment also includes a first circulation receiving device 6 and a second circulation receiving device 7; The first receiving tank 601 of the first liquid inlet pipe and the first liquid outlet pipe, the first circulation pump 602 arranged on the first liquid inlet pipe; the second circulation receiving device includes a The second liquid inlet pipe and the second receiving tank 701 of the second liquid outlet pipe are arranged on the second circulating pump 702 on the second liquid inlet pipe.

[0076] The tail gas treatment system for preparing zirconium oxychloride by the boiling chlorination method described in this embodiment als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com