Sodium alginate/hydroxymethyl cellulose/gelatin interpenetrating polymer network gradient cross-linking type medical wound transparent dressing and preparation method thereof

A technology of hydroxymethyl cellulose and interpenetrating network, applied in the field of medicine, can solve the problems of foreign body reaction, ingredient allergy, high product cost, etc., and achieve the effects of good biocompatibility, simple preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

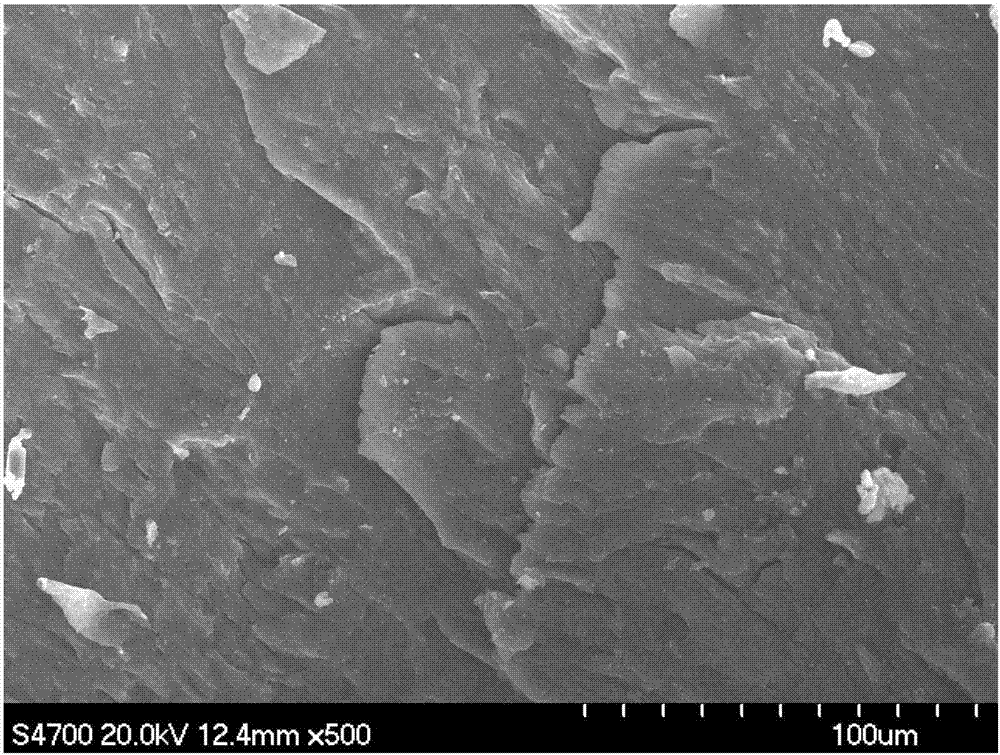

[0023] Sodium alginate, hydroxymethylcellulose and gelatin were weighed according to 5.0% of the mass of distilled water. The masses of sodium alginate, hydroxymethylcellulose and gelatin are 1.0 g, 1.0 g and 1.0 g, respectively. Add it into distilled water at 20°C and stir to dissolve evenly to obtain a sodium alginate / hydroxymethylcellulose / gelatin blend solution. Prepare sodium alginate as a 5.0% aqueous solution, add equimolar sodium periodate and stir in the dark for 12 hours, add ethylene glycol to terminate the reaction for 1 hour, add NaCl for mixing, and then add an equal volume of ethanol to precipitate the product. The product was filtered with an equal volume of C 2 h 5 OH / H 2 O and C 2 h 5 Rinse with OH and dry in vacuum for 24h. Add 1.5g of 1,2-propanediol and 1.5g of glycerin into the sodium alginate / hydroxymethylcellulose / gelatin blend solution, stir evenly, add 1.0g of oxidized sodium alginate and 2.0g of PEGDMA, stir in distilled water at 20°C Dissolve...

Embodiment 2

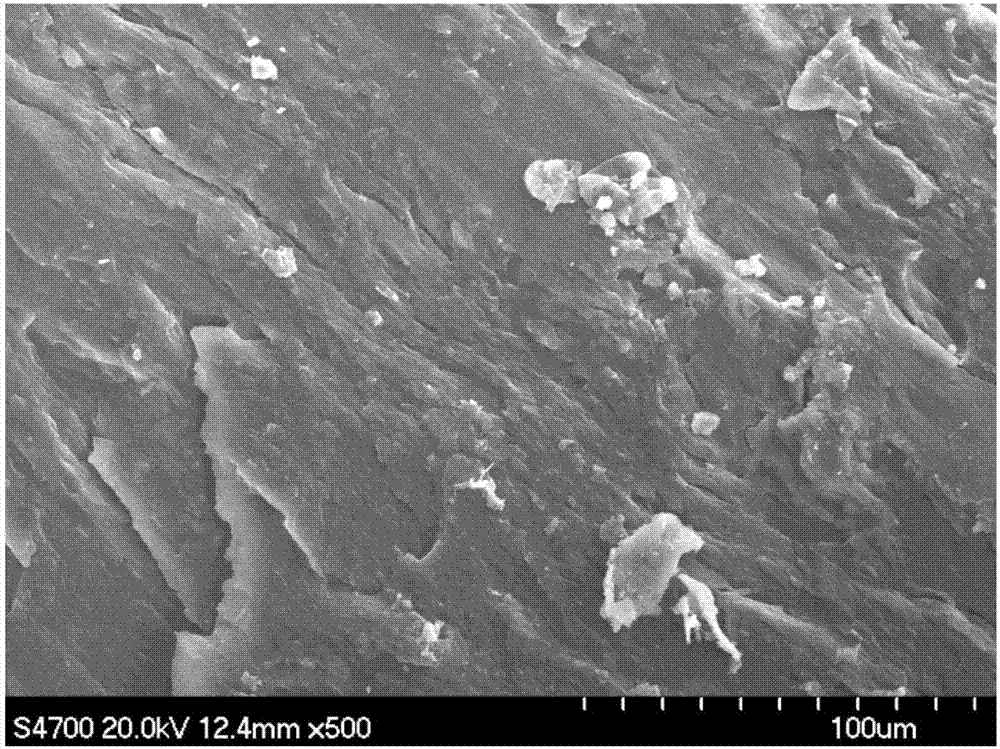

[0025] Sodium alginate, hydroxymethylcellulose and gelatin were weighed according to 5.0% of the mass of distilled water. The masses of sodium alginate, hydroxymethylcellulose and gelatin are 1.0 g, 1.0 g and 1.0 g, respectively. Add it into distilled water at 20°C and stir to dissolve evenly to obtain a sodium alginate / hydroxymethylcellulose / gelatin blend solution. Prepare sodium alginate as a 5.0% aqueous solution, add equimolar sodium periodate and stir in the dark for 12 hours, add ethylene glycol to terminate the reaction for 1 hour, add NaCl for mixing, and then add an equal volume of ethanol to precipitate the product. The product was filtered with an equal volume of C 2 h 5 OH / H 2 O and C 2 h 5Rinse with OH and dry in vacuum for 24h. Add 1.5g of 1,2-propanediol and 1.5g of glycerin into the sodium alginate / hydroxymethylcellulose / gelatin blend solution, stir evenly, add 1.0g of oxidized sodium alginate and 2.0g of PEGDMA, stir in distilled water at 20°C Dissolve ...

Embodiment 3

[0027] Sodium alginate, hydroxymethylcellulose and gelatin were weighed according to 5.0% of the mass of distilled water. The masses of sodium alginate, hydroxymethylcellulose and gelatin are 1.0 g, 1.0 g and 1.0 g, respectively. Add it into distilled water at 20°C and stir to dissolve evenly to obtain a sodium alginate / hydroxymethylcellulose / gelatin blend solution. Prepare sodium alginate as a 5.0% aqueous solution, add twice the molar ratio of sodium periodate and stir in the dark for 12 hours, add ethylene glycol to terminate the reaction for 1 hour, add NaCl for mixing, and then add an equal volume of ethanol to precipitate the product. The product was filtered with an equal volume of C 2 h 5 OH / H 2 O and C 2 h 5 Rinse with OH and dry in vacuum for 24h. Add 1.5g of 1,2-propanediol and 1.5g of glycerin into the sodium alginate / hydroxymethylcellulose / gelatin blend solution, stir evenly, add 1.0g of oxidized sodium alginate and 2.0g of PEGDMA, stir in distilled water at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com