Tea leaf processing technology

A processing technology and tea technology, applied in the field of tea processing technology, can solve problems such as uneven aroma of tea leaves, and achieve the effects of good quality, increased contact area, and uniform adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

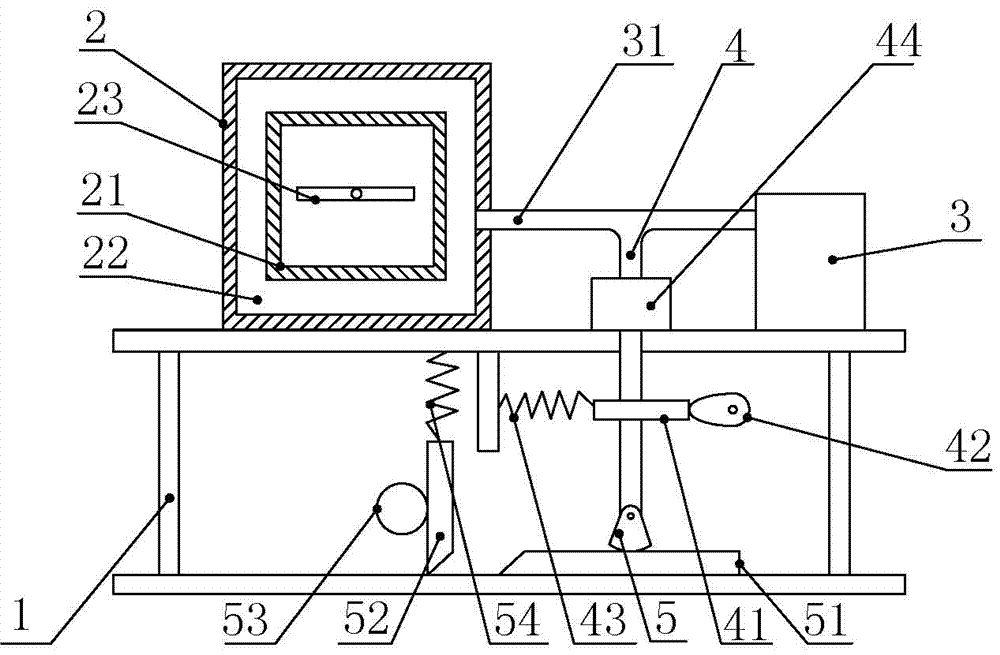

[0026] The reference signs in the accompanying drawings of the description include: frame 1, fermentation box 2, charging box 21, cavity 22, rotating plate 23, steam generator 3, main pipe 31, branch pipe 4, valve plate 41, cam 42, second A spring 43, a pressurizing pump 44, a sector gear 5, a first rack 51, a second rack 52, a gear 53, and a second spring 54.

[0027] The tea processing technology of the present invention comprises the following operations:

[0028] Finishing: Put the tea leaves in a frying pan for frying, evaporate part of the water in the fresh tea leaves, make the tea leaves soft, and at the same time inhibit the oxidase activity of the tea leaves, control the enzymatic oxidation of tea polyphenols in the tea leaves, and facilitate subsequent rolling and forming ;

[0029] Kneading: Put the tea leaves in a kneading machine for the first kneading, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com