Microbial preparation for repairing hydroxymethyl cellulose wastewater and preparation method of microbial preparation

A technology of hydroxymethyl cellulose and microbial preparations, which is applied in the field of microorganisms, can solve the problems of poor treatment effect and difficulty in selecting microbial species, and achieve the effects of rapid adaptation, good effect of repairing wastewater, promotion of proliferation and enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

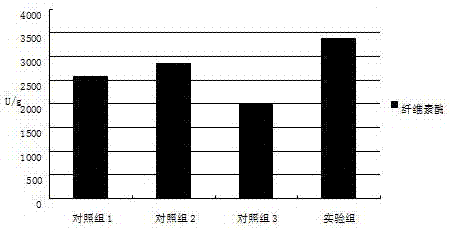

Image

Examples

Embodiment 1

[0029] A microbial preparation for repairing hydroxymethylcellulose wastewater, which is composed of the following raw materials: acclimatization liquid of Anabaena variabilis, acclimatization liquid of Cellulomonas chrysogenum, acclimation liquid of Bacillus subtilis, acclimation liquid of Aspergillus niger; The above-mentioned Anabaena variabilis liquid, Cellulomonas flavinogenes domestication liquid, Bacillus subtilis domestication liquid and Aspergillus niger domestication liquid are used separately.

[0030] The Anabaena variabilis domestication solution is prepared according to the following process: take hydroxymethylcellulose wastewater, add 0.5g of urea, 6g of sodium bicarbonate, 0.2g of dipotassium hydrogenphosphate, and 0.2g of potassium dihydrogenphosphate to the wastewater , sodium chloride 0.3g, potassium chloride 0.3g, ferric ammonium citrate 0.03g, edetate disodium 0.03g, stir evenly, and set the volume to 1L to prepare algae acclimation medium; The algae were ...

Embodiment 2

[0038] A microbial preparation for repairing hydroxymethylcellulose wastewater, which is composed of the following raw materials: acclimatization liquid of Anabaena variabilis, acclimatization liquid of Cellulomonas chrysogenum, acclimation liquid of Bacillus subtilis, acclimation liquid of Aspergillus niger; The above-mentioned Anabaena variabilis liquid, Cellulomonas flavinogenes domestication liquid, Bacillus subtilis domestication liquid and Aspergillus niger domestication liquid are used separately.

[0039] The Anabaena variabilis domestication solution is prepared according to the following process: take hydroxymethylcellulose wastewater, add 0.5g of urea, 6g of sodium bicarbonate, 0.2g of dipotassium hydrogenphosphate, and 0.2g of potassium dihydrogenphosphate to the wastewater , sodium chloride 0.3g, potassium chloride 0.3g, ferric ammonium citrate 0.03g, edetate disodium 0.03g, stir evenly, and set the volume to 1L to prepare algae acclimation medium; The algae were cu...

Embodiment 3

[0047] The hydroxymethyl cellulose wastewater used in Example 1-2 of the present invention is pretreated wastewater, and the pretreatment steps are: the hydroxymethyl cellulose production wastewater first passes through the flocculation sedimentation tank, the flocculant is aluminum sulfate, and the addition amount is 1-3wt%, and then treated by micro-electrolysis, and then enter the acid hydrolysis adjustment tank, adjust the pH of the solution to 6.5-7; the main indicators of the pretreated wastewater are: COD 1094 mg / L, BOD 613 mg / L, ammonia nitrogen 215 mg / L, SS 41 mg / L, total salt 389 mg / L, cellulose 326 mg / L, hydroxymethyl cellulose 592 mg / L.

[0048] Taking Example 1 of the present invention as an example, the use method of the microbial preparation of the present invention is: enter the microbial reaction tank through the pretreated waste water, inoculate the Anabaena variabilis domestication solution according to the inoculum size of 4%, after cultivating for 12 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com