System and method for co-producing low carbon olefin and ammonia by low carbon alkane

A technology of low-carbon olefins and low-carbon alkanes, applied in chemical instruments and methods, preparation/separation of ammonia, hydrocarbons, etc., can solve problems such as large investment, high energy consumption, waste gas, waste residue and wastewater pollution, and shorten The effect of high flow and process integration and less waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

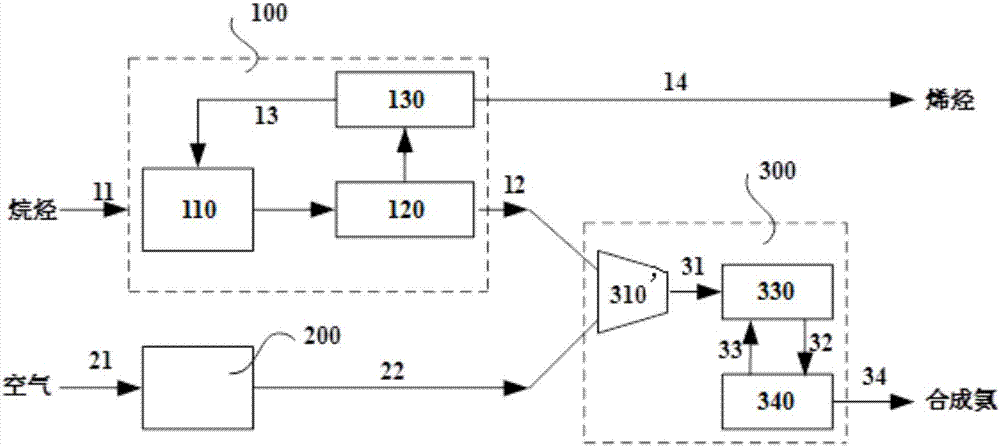

[0024] A factory uses propane as raw material, the application such as figure 1 The shown system co-produces propylene and ammonia, and the system includes an alkane dehydrogenation unit 100, an air separation unit 200 and an ammonia synthesis unit 300, wherein the alkane dehydrogenation unit 100 is connected to the ammonia synthesis unit 300 through a hydrogen delivery pipeline 12, and the air separation unit 200 is connected with ammonia synthesis device 300 through nitrogen delivery pipeline 22.

[0025] Specifically:

[0026] The alkane dehydrogenation unit 100 comprises an alkane dehydrogenation reaction device 110, a hydrogen hydrocarbon separation device 120 and an alkane separation device 130, and the alkane dehydrogenation reaction device 110 is connected with the hydrogen hydrocarbon separation device 120, and the alkane separation device 130 is connected with the alkane circulation pipeline 13 The alkane dehydrogenation reaction equipment 110 is connected, the hydr...

Embodiment 2

[0036] A factory uses isobutane as raw material, the application such as figure 1 The shown system co-produces isobutene and ammonia, and the system includes an alkane dehydrogenation unit 100, an air separation unit 200 and an ammonia synthesis unit 300, wherein the alkane dehydrogenation unit 100 is connected to the ammonia synthesis unit 300 through a hydrogen delivery pipeline 12, and the air separation unit 200 is connected with ammonia synthesis device 300 through nitrogen delivery pipeline 22.

[0037] Wherein, the alkane dehydrogenation unit 100 includes alkane dehydrogenation reaction equipment 110, hydrogen hydrocarbon separation equipment 120 and alkane separation equipment 130, alkane dehydrogenation reaction equipment 110 is connected with hydrogen hydrocarbon separation equipment 120, and alkane separation equipment 130 passes through the alkane circulation pipeline 13 is connected to the alkane dehydrogenation reaction equipment 110, the hydrogen delivery pipeli...

Embodiment 3

[0047] A factory uses propane as raw material, the application such as figure 2 The system shown co-produces propylene and ammonia. The difference from Example 1 is that in this example, in order to reduce equipment investment, a hydrogen-nitrogen mixed gas compressor 310' is used to replace the hydrogen compressor 310 and nitrogen compressor 320 in Example 1. The alkane dehydrogenation device 100 The high-purity hydrogen and high-purity nitrogen from the air separation unit 200 are boosted by the hydrogen-nitrogen mixture compressor 310 ′, and then enter the ammonia synthesis reaction device 330 to generate ammonia.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com