IGBT serial-connected composite voltage balancing circuit with grid-side and load-side control

A voltage equalizing circuit and load-side technology, applied in circuits, electrical components, electronic switches, etc., can solve problems such as difficulty in guaranteeing reliability, increased power consumption of IGBT switches, and prolonged turn-off time, so as to facilitate integration and mass production, Effect of reducing voltage and current spikes and ensuring operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

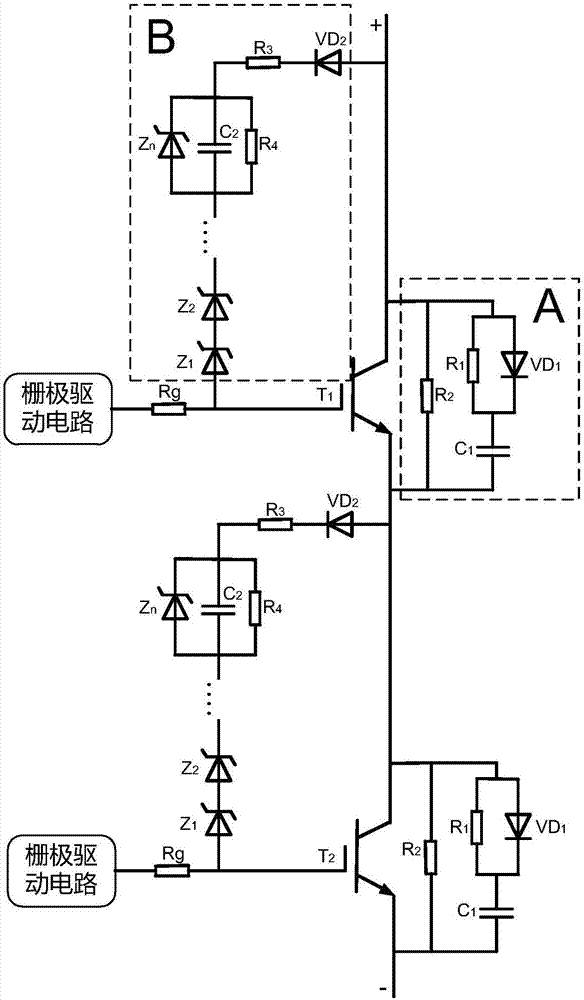

[0022] Such as figure 1 As shown, the present invention includes at least two IGBTs connected in series, and each IGBT is connected to a voltage equalizing circuit;

[0023] Such as figure 1 As shown, the present invention includes a load balancing control circuit A and a gate clamping circuit B, the load balancing control circuit A is connected in parallel to the collector and emitter of each IGBT, and the gate clamping circuit B is connected in parallel to the collector of each IGBT and gate.

[0024] Such as figure 1 As shown, the load balancing control circuit A is composed of capacitor C1, diode VD1, and resistors R1 and R2. The diode VD1 and resistor R1 are connected in parallel to the emitter of the IGBT through capacitor C1, and the resistor R2 is connected in parallel to the collector and emitter of the IGBT. .

[0025] Such as figure 1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com