Mask, hole forming method, display substrate forming method, display substrate and display device

A technology for display substrates and masks, which is applied in the photoengraving process of the pattern surface, the originals for opto-mechanical processing, optics, etc., and can solve the problems of the decrease of the pixel aperture ratio, the influence of the connectivity, and the large difference in the pitch of the via holes. , to achieve the effect of reducing contact resistance, improving connectivity, and reducing level difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

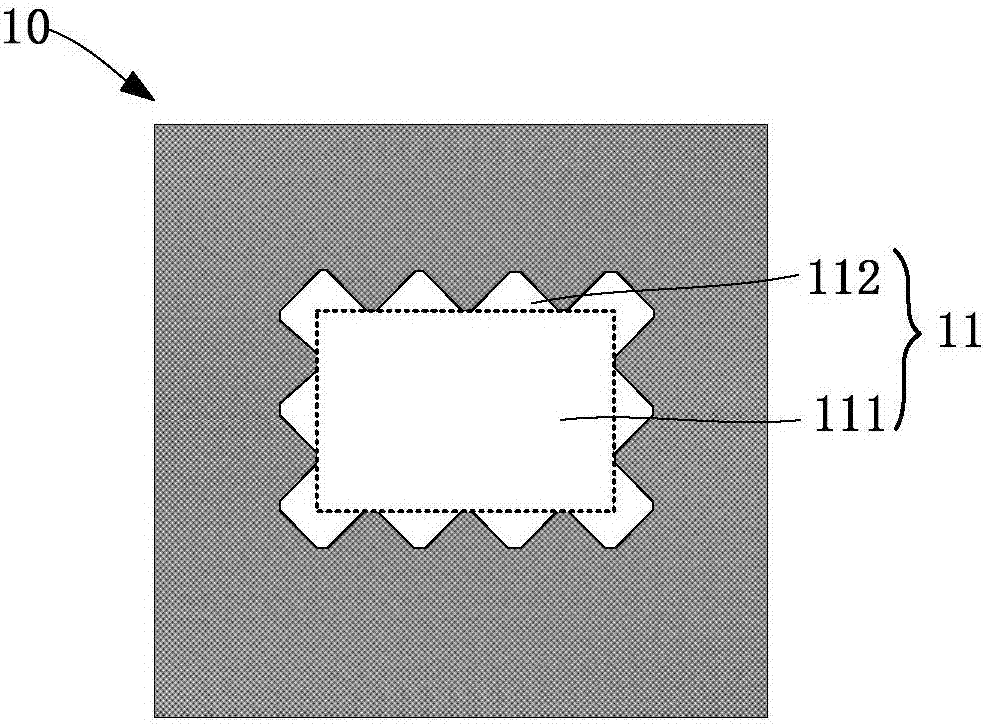

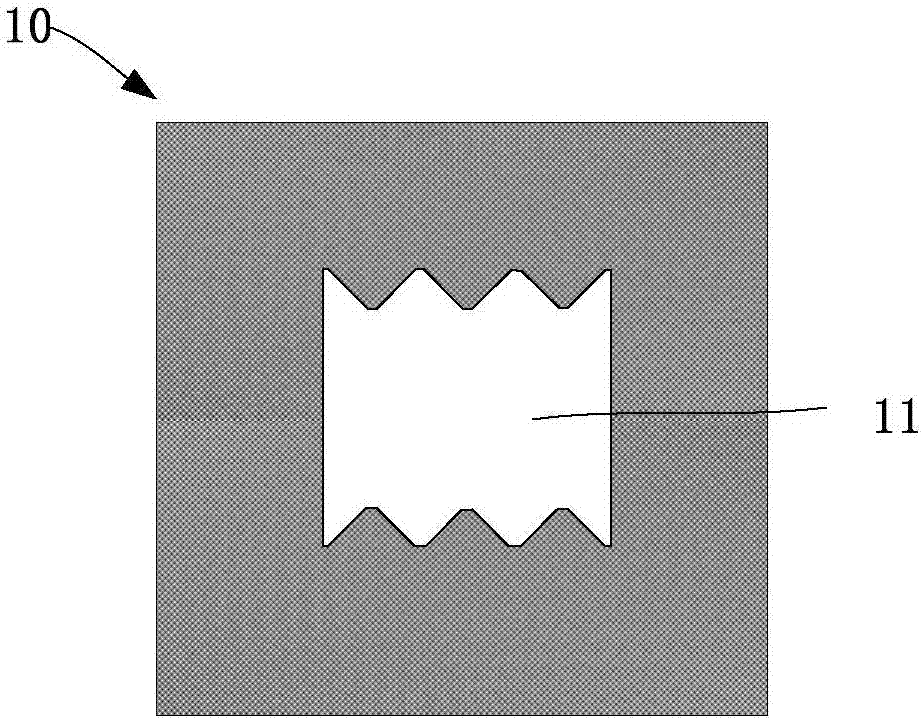

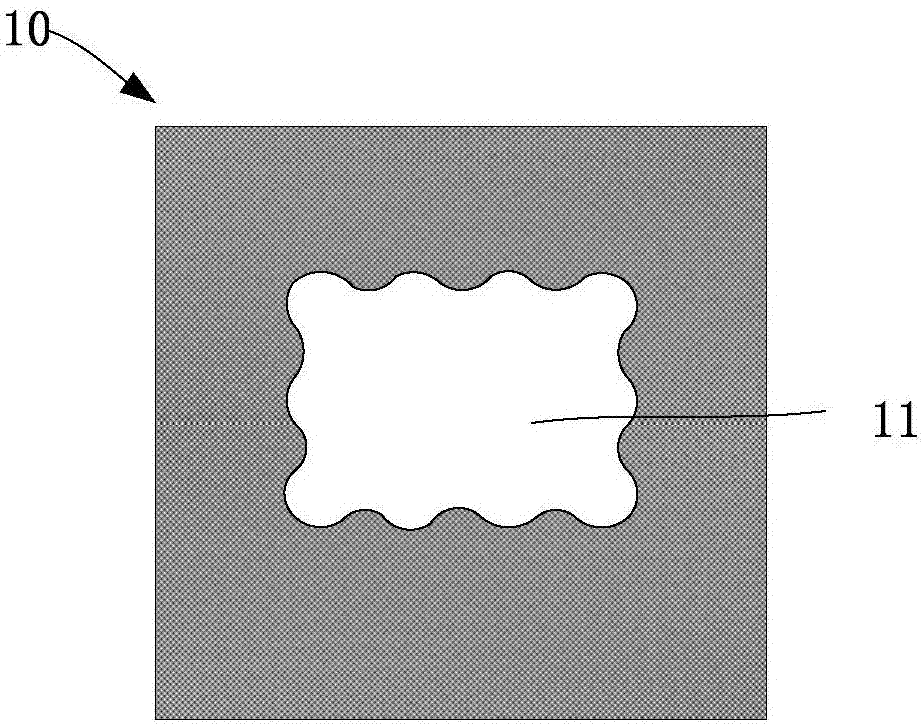

[0039] In order to solve the problem that the contact area of the via hole between the upper and lower conductive layers electrically connected through the via hole is small on the existing display substrate, resulting in a large contact resistance of the via hole, and the large difference of the via hole section affects the connectivity. The present invention provides a A method for forming a mask plate, a via hole and a display substrate, a display substrate and a device, which can increase the contact area of the via hole between the upper and lower conductive layers electrically connected through the via hole, reduce the contact resistance of the via hole and the level difference of the via hole, Improve connectivity.

[0040] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the following will clearly and completely describe the technical solutions of the embodiments of the present invention in conj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com