Method for preparing high-purity polyfructose through simulated moving bed chromatography

A technology for simulating moving bed and polyfructose is applied in the field of polyfructose preparation, which can solve the problem of low purity of polyfructose, and achieve the effects of realizing continuous operation, reducing production cost and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation of inulin refined liquid.

[0025] Get 500g fresh chicory clean, peel, grind and crush; The chicory of crushing is added in the Tris-HCl buffer solution that contains pectinase, the concentration of described Tris-HCl buffer solution is 1mol / L, and pH is 6.8, fruit The amount of glue enzyme added is 1000U / L, stirred at 35 degrees Celsius for 3 hours, then heated to 100 degrees Celsius, and stirred for 5 hours; filtered the inulin extract to obtain a crude inulin extract;

[0026] Carry out decolorization, debittering, and desalination treatment to the inulin crude extract, pass the inulin crude extract through activated carbon, chitosan, cationic macroporous resin, and nanofiltration membrane successively, the cationic macroporous resin is H103, and the The nanofiltration membrane used is DL8040F to obtain the inulin refined solution.

Embodiment 2

[0028] A method utilizing simulated moving bed chromatography to prepare high-purity polyfructose, the method comprising the steps of:

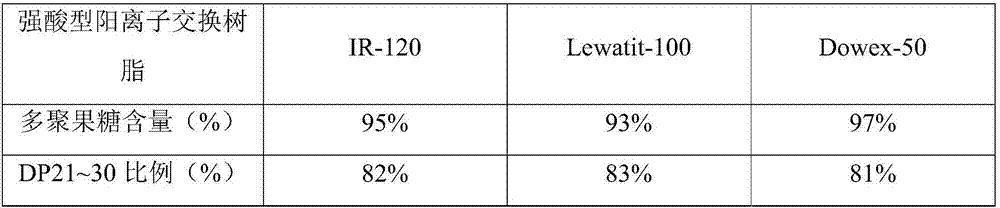

[0029] The inulin refined liquid is added to a simulated moving bed chromatographic separation device for separation and purification, using water as the eluent. The simulated moving bed includes areas I, II, III, and IV, and each area includes 6 chromatographic columns. Among them, the chromatographic columns in zone Ⅰ and zone Ⅱ are filled with IR-120 strong acid cation exchange resin, and the chromatographic columns in zone Ⅲ and zone Ⅳ are filled with Y-type molecular sieves;

[0030] The process parameters of separation and purification are as follows:

[0031] The operating temperature is 45°C, the pressure is 0.15Mpa, the flow rate of the feed liquid is 50mL / min, and the flow rate of the eluent is 50mL / min. It is 55cm / h, and the flow velocity in IV district is 14cm / h; The obtained polyfructose effluent solution is evaporated and conce...

Embodiment 3

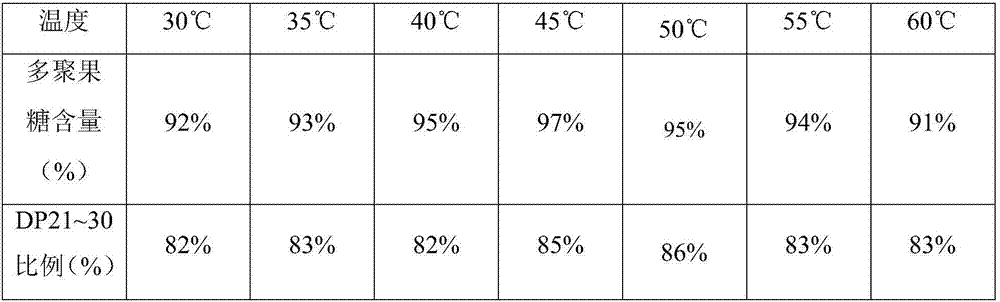

[0033] Other conditions were the same as in Example 2, except that the operating temperature of the simulated moving bed chromatographic separation device was adjusted to 30°C, 35°C, 40°C, 45°C, 50°C, 55°C, and 60°C. Detect the polyfructose content and degree of polymerization at the polyfructose outflow port, and the test results are shown in the table below.

[0034] Table 1 The influence of temperature on the separation efficiency of polyfructose

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com