Preparation method of ITO tubular target material

A technology of tubular and target materials, which is applied in the direction of manufacturing tools, auxiliary molding equipment, metal material coating technology, etc., and can solve the problems of difficult control of thin film deposition thickness uniformity, poor uniformity of etching target materials, and low target material utilization. , to achieve good market prospects, easy to automate production, reduce labor intensity and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the ITO tubular target described in this embodiment specifically includes the following steps:

[0023] (1) Mix nanoscale ITO powder with binder PVA and water. The mass percentage of solid phase in the mixed slurry is 65%, the mass percentage of binder PVA is 1%, and the mass percentage of water is 34%;

[0024] (2) Inject the slurry in step (1) at a rate of 19 mL / min into the mold rotating at a rate of 8000r / min. After the grouting is completed, the mold continues to rotate for 10 minutes, and then the mold is placed in an ultrasonic vibrator to maintain 30s, the ultrasonic power is 1.5kw, and the ITO tubular target blank is obtained by demoulding;

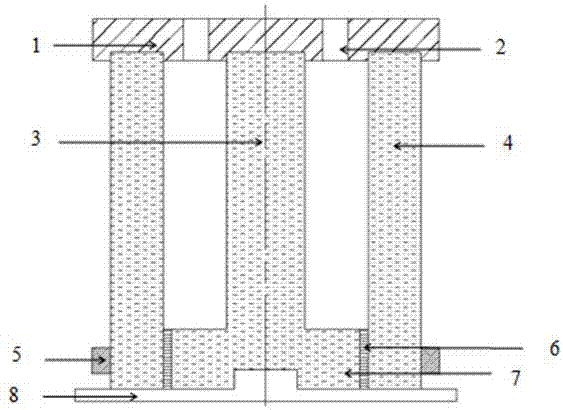

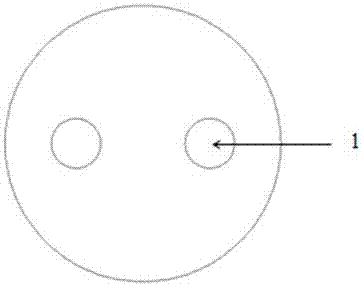

[0025] The mold used in this step is as figure 1 , 2 The mold includes a flexible cover 1, a grouting port 2, a ceramic filter core 3, a ceramic filter cover 4, a cover clip 5, a sealing ring 6, a base 7, a fixed rotating shaft 8, and a protrusion is provided on the fixed rotating shaft 8 The ...

Embodiment 2

[0030] The preparation method of the ITO tubular target described in this embodiment specifically includes the following steps:

[0031] (1) Mix nanoscale ITO powder with binder PVA and water. The mass percentage of solid phase in the mixed slurry is 68%, the mass percentage of binder PVA is 2%, and the mass percentage of water is 30%;

[0032] (2) Inject the slurry in step (1) at a rate of 21mL / min into the mold rotating at a rate of 9000r / min. After the grouting is completed, the mold continues to rotate for 13min, and then the mold is placed in an ultrasonic vibrator for 35s , the ultrasonic power is 1.3kw, and the ITO tubular target green body is obtained by demoulding; the mold used in this step has the same structure as that in Example 1, and the flexible cover 1 is a nitrile rubber cover;

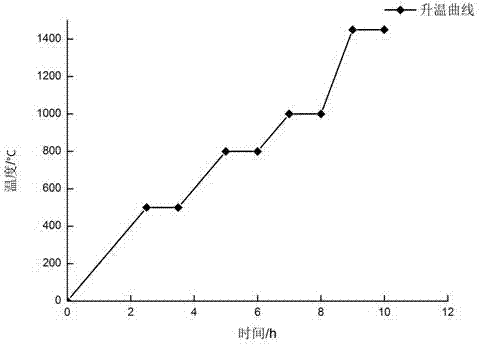

[0033] (3) Put the ITO tubular target green body obtained in step (2) into the degreasing furnace for degreasing treatment. The degreasing treatment process is: increase the tempera...

Embodiment 3

[0036] The preparation method of the ITO tubular target described in this embodiment specifically includes the following steps:

[0037] (1) Mix nanoscale ITO powder with binder PVA and water. The mass percentage of solid phase in the mixed slurry is 70%, the mass percentage of binder PVA is 2%, and the mass percentage of water is 28%;

[0038](2) Inject the slurry in step (1) at a rate of 23mL / min into the mold rotating at a rate of 10000r / min. After the grouting is completed, the mold continues to rotate for 15min, and then the mold is placed in an ultrasonic vibrator for 50s , the ultrasonic power is 1kw, and the ITO tubular target green body is obtained by demoulding; the mold used in this step is the same as that in Example 1, except that a grouting port 2 is provided;

[0039] (3) Put the ITO tubular target blank obtained in step (2) into a degreasing furnace for degreasing treatment. The degreasing treatment process is: raise the temperature to 620 °C at a heating rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com