A water-resistant white real stone paint

A technology of real stone paint and water-based acrylate, applied in the field of real stone paint, can solve the problems of whitening of the coating when it encounters water, reduce the surface decoration and service life of real stone paint, affect the quality and decorative effect, and achieve good film-forming properties. Excellent stain resistance and the effect of overcoming the phenomenon of rain marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

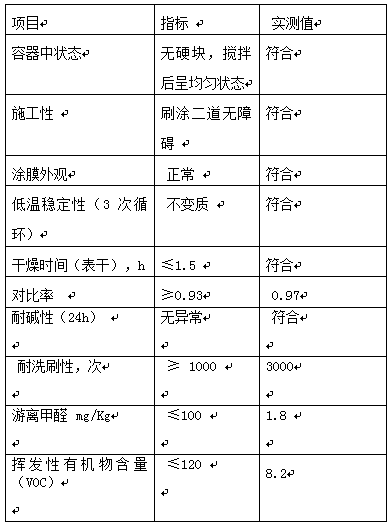

Examples

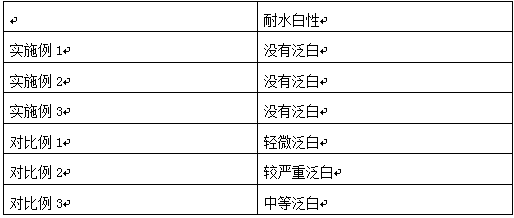

Embodiment 1

[0016] A water-resistant white real stone paint, which is made of the following components in parts by weight: water-based acrylate emulsion 12, film-forming aid 0.5, defoamer 0.11, cellulose ether 0.12, colored sand 68, silica sol 0.2, corn hydroxypropyl Base starch 3.5, modified calcined clay 6, water 12;

[0017] The modified calcined clay is obtained by calcining, acid leaching, low-temperature plasma treatment, alkali leaching, water washing and drying.

[0018] The film-forming aid is formed by mixing polyethylene glycol and propylene glycol phenyl ether in a mass ratio of 5:1.

[0019] Described defoamer adopts silicone defoamer.

[0020] The mesh number of the colored sand is 120 mesh.

[0021] The preparation method of the corn hydroxypropyl starch is as follows: soak the corn starch in sodium bicarbonate with a mass fraction of 0.22% at 30°C for 30 minutes, filter, wash with water, and dry to constant weight, then mix the corn starch with propylene oxide , sodium ...

Embodiment 2

[0025] A water-resistant white genuine stone paint, which is made of the following components in parts by weight: 15 water-based acrylate emulsion, 1 film-forming aid, 0.13 defoamer, 0.16 cellulose ether, 72 colored sand, 0.5 silica sol, and corn hydroxypropyl Base starch 3.8, modified calcined clay 8, water 18;

[0026] The modified calcined clay is obtained by calcining, acid leaching, low-temperature plasma treatment, alkali leaching, water washing and drying.

[0027] The film-forming aid is formed by mixing polyethylene glycol and propylene glycol phenyl ether in a mass ratio of 5:1.

[0028] Described defoamer adopts silicone defoamer.

[0029] The mesh number of the colored sand is 150 mesh.

[0030] The preparation method of the corn hydroxypropyl starch is as follows: soak the corn starch in sodium bicarbonate with a mass fraction of 0.22% at 30°C for 30 minutes, filter, wash with water, and dry to constant weight, and then mix the corn starch with propylene oxide ...

Embodiment 3

[0034] A water-resistant white real stone paint, which is made of the following components in parts by weight: 14 water-based acrylate emulsions, 0.8 film-forming aids, 0.12 defoamers, 0.14 cellulose ethers, 70 colored sands, 0.3 silica sols, and corn hydroxypropyl Base starch 3.6, modified calcined clay 7, water 15;

[0035] The modified calcined clay is obtained by calcining, acid leaching, low-temperature plasma treatment, alkali leaching, water washing and drying.

[0036] The film-forming aid is formed by mixing polyethylene glycol and propylene glycol phenyl ether in a mass ratio of 5:1.

[0037] Described defoamer adopts silicone defoamer.

[0038] The mesh number of the colored sand is 140 mesh.

[0039] The preparation method of the corn hydroxypropyl starch is as follows: soak the corn starch in sodium bicarbonate with a mass fraction of 0.22% at 30°C for 30 minutes, filter, wash with water, and dry to constant weight, then mix the corn starch with propylene oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com