Double-station feeding device and oil press with same

A feeding device and double-station technology, applied in positioning devices, presses, feeding devices, etc., can solve the problems of low production efficiency, increased labor costs, and low automation, so as to reduce labor costs, improve automation, The effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

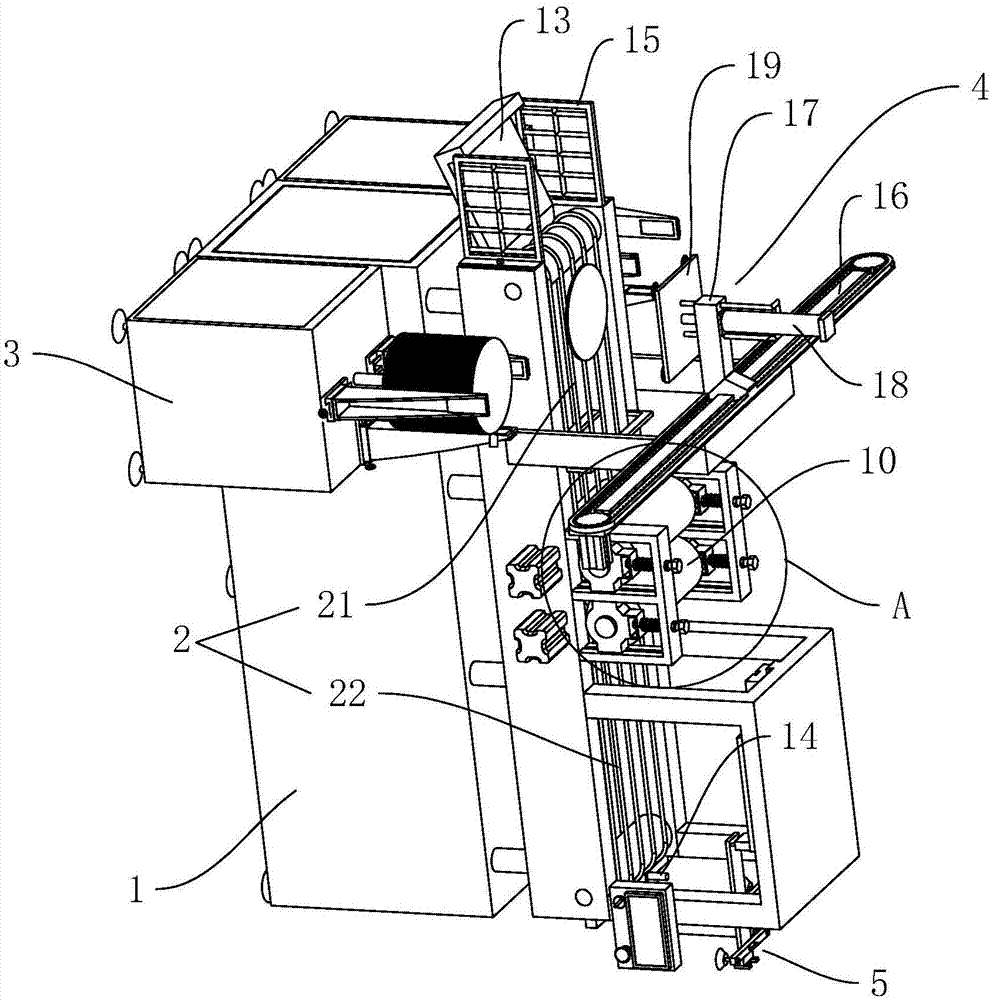

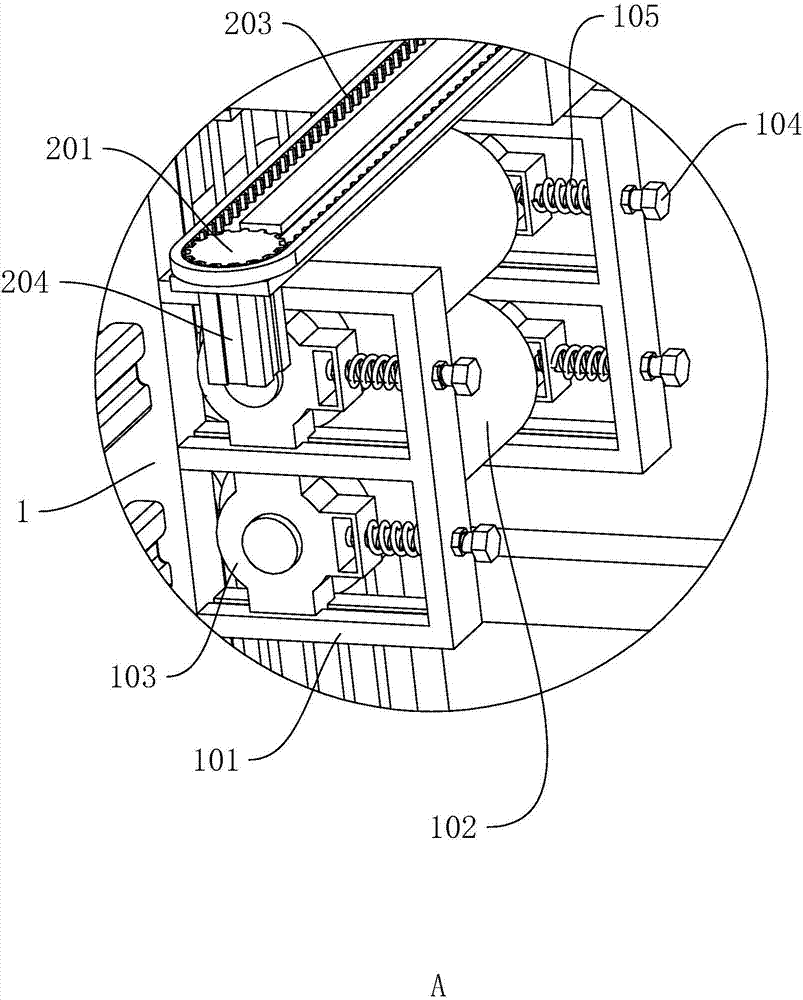

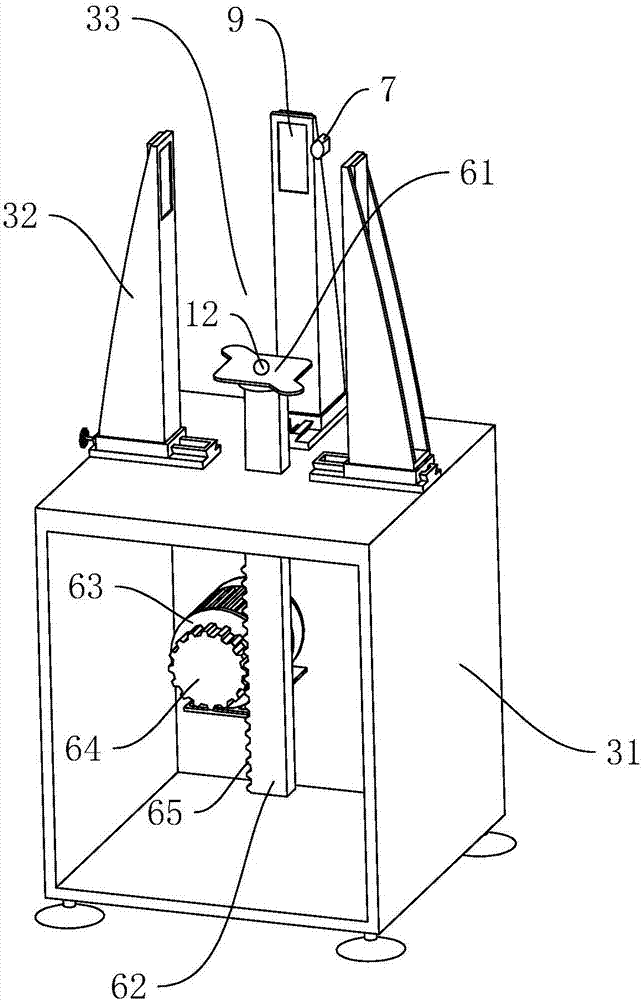

[0043] Embodiment one: a kind of double-station feeding device, such as figure 1 , image 3 As shown, it includes a machine base 1, the machine base 1 is provided with a conveying mechanism 2 along the length direction, the front end of the machine base 1 is provided with a loading mechanism 3 for loading workpieces to be processed, and the front end of the machine base 1 is provided with a reclaiming robot 4 for Grasp the workpiece in the loading mechanism 3 to the conveying mechanism 2 for conveying; the rear end of the base 1 is provided with a feeding robot 5, which is used to grab the workpiece at the end of the conveying mechanism 2 to the next process, and the feeding of the feeding robot 5 The speed is greater than the retrieving speed of the retrieving robot 4, which accelerates the workpiece to enter the next process; the charging mechanism 3 includes a fuselage 31 arranged at the front end of the machine base 1 and three baffle plates 32 vertically arranged on the u...

Embodiment 2

[0051] Embodiment two: a kind of double-station feeding device, such as Figure 7 , Figure 8 As shown, the difference from Embodiment 1 is that an accommodation groove 211 is provided on the upper end of the baffle plate 32 close to the workpiece side, and the accommodation groove 211 is provided with a separation plate 212 matched with the accommodation groove 211, and the lower end of the separation plate 212 is hinged on The lower end of the accommodation groove 211, the upper end of the separation plate 212 and the accommodation groove 211 are provided with an abutment spring 213, one end of the abutment spring 213 is fixed on the side of the separation plate 212 facing the accommodation groove 211, and the other end is fixed on the bottom of the accommodation groove 211. The side of the plate 212 facing the workpiece is longitudinally provided with a plurality of ribs 214, and the ribs 214 form an angle of 60 degrees with the horizontal plane; so that the separating plat...

Embodiment 3

[0052] Embodiment three: a kind of hydraulic press, such as Figure 9As shown, the hydraulic press 23 is included, and the hydraulic press 23 is a common pressing and forming equipment in the prior art. There is no need to go into details here. The double-station feeding device described in Embodiment 1 is arranged on one side of the hydraulic press 23. The station feeding device is set in linkage with the hydraulic press 23. When the feeding device automatically sends the workpiece into the working position of the hydraulic press 23, the hydraulic press 23 is automatically started to work; when the feeding device feeds the workpiece again, it will automatically push out the pressed semi-finished workpiece The working position of the hydraulic press 23, and the workpiece to be processed is placed on the working position of the hydraulic press 23, thereby improving production efficiency, eliminating the need for special staff, reducing labor costs, and avoiding safety accidents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com