Amphoteric ion exchange membrane for fuel cell and preparation method of amphoteric ion exchange membrane

A technology of amphoteric ions and fuel cells, which is applied in the field of ion exchange membranes and its preparation, can solve the problems of fuel penetration and low ion conductivity, and achieve the effects of improving fuel utilization, overcoming low ion conductivity, and good ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

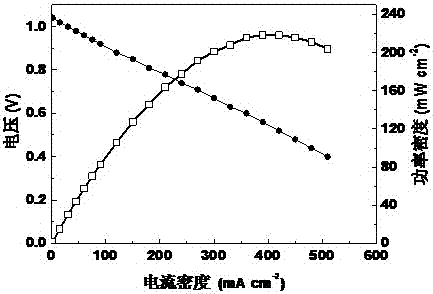

Image

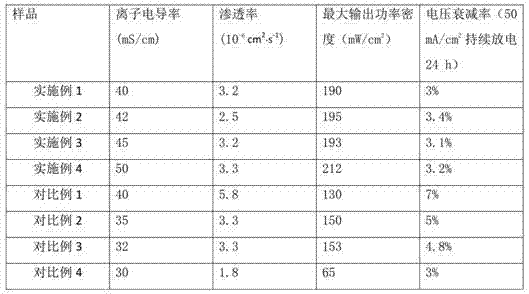

Examples

Embodiment 1

[0030] 1) Dissolve 1 g of nickel chloride powder in 50 mL of deionized water, heat and stir to obtain a nickel chloride solution; immerse anion exchange resin particles with a particle diameter of 50 microns in the nickel chloride solution for 1 hour and take out the particles; The particles were immersed in a 4M sodium hydroxide solution, and stirred and reacted at 50 degrees Celsius for 12 hours; the particles were taken out and washed repeatedly to remove residual lye, and then dried at room temperature to obtain nickel oxyhydroxide-loaded anion exchange resin particles.

[0031] 2) Dissolve 1 g of PVA powder in 50 mL of deionized water, heat and stir at 80°C for 2 hours to obtain a PVA gel; add 5 mL of 4% Nafion solution to the PVA gel, heat and stir to obtain PVA-Nafion gel.

[0032] 3) Part of the PVA-Nafion gel is coated with a film with a thickness of 100 microns on the glass substrate by the film coating method, and dried naturally; the thickness of the dried film is ...

Embodiment 2

[0038] The difference from Example 1 is that the amount of nickel chloride powder in step 1) is 5 g, and other parameters are the same.

Embodiment 3

[0040] The difference from Example 1 is that the diameter of the anion exchange resin particles is 500 microns, the thickness of the wet film coated in step 6) is 625 microns, and other parameters are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com