Photoelectric composite cable and manufacturing method thereof

A technology of photoelectric composite cable and manufacturing method, which is applied in the direction of cable/conductor manufacturing, power cables including optical transmission components, power cables, etc., and can solve the problems of oil well optical cable wires being unable to supply power, wire insulation capacity decreasing, and wire insulation outer diameter being reduced And other problems, achieve good hydrogen resistance performance, improve service life, improve the effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions of each exemplary embodiment provided by the present invention with reference to the accompanying drawings in the embodiments of the present invention. In the case of no conflict, the following embodiments and technical features thereof can be combined with each other.

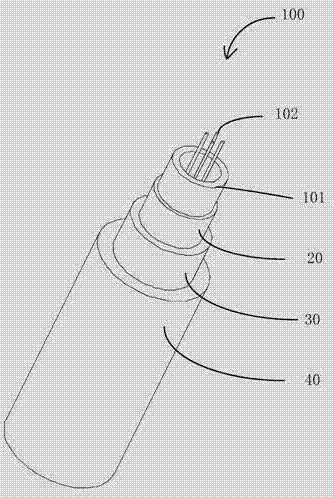

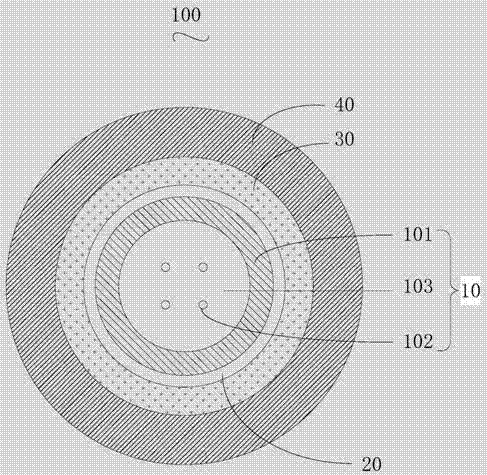

[0037] see figure 1 and figure 2 , is a structural view and a cross-sectional view of the first embodiment of the photoelectric composite cable of the present invention. The photoelectric composite cable 100 for oil wells of the present invention can be used in exploration systems in oil wells as a transmission medium to withstand harsh environments such as downhole high temperature, high pressure, and high acid corrosion and maintain long-term operation.

[0038] The photoelectric composite cable 100 of the present invention includes an optical unit 10, a conductive layer 20 coated on the surface of the optical unit 10, an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com