Reaction control and mass spectrometry setup for in situ cell coupling of x-ray characterization equipment

An in-situ reaction and mass spectrometry analysis technology, which is applied in the direction of material analysis, material analysis, and measurement devices using wave/particle radiation, can solve the problem of no matching reaction gas composition control scheme, and achieve the effect of minimizing time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

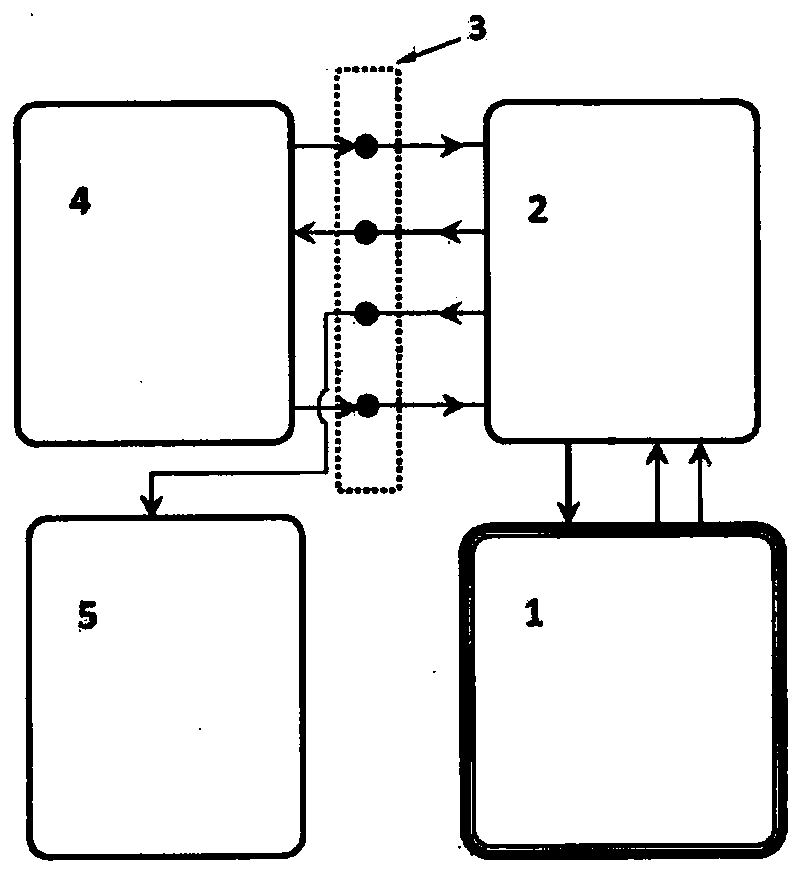

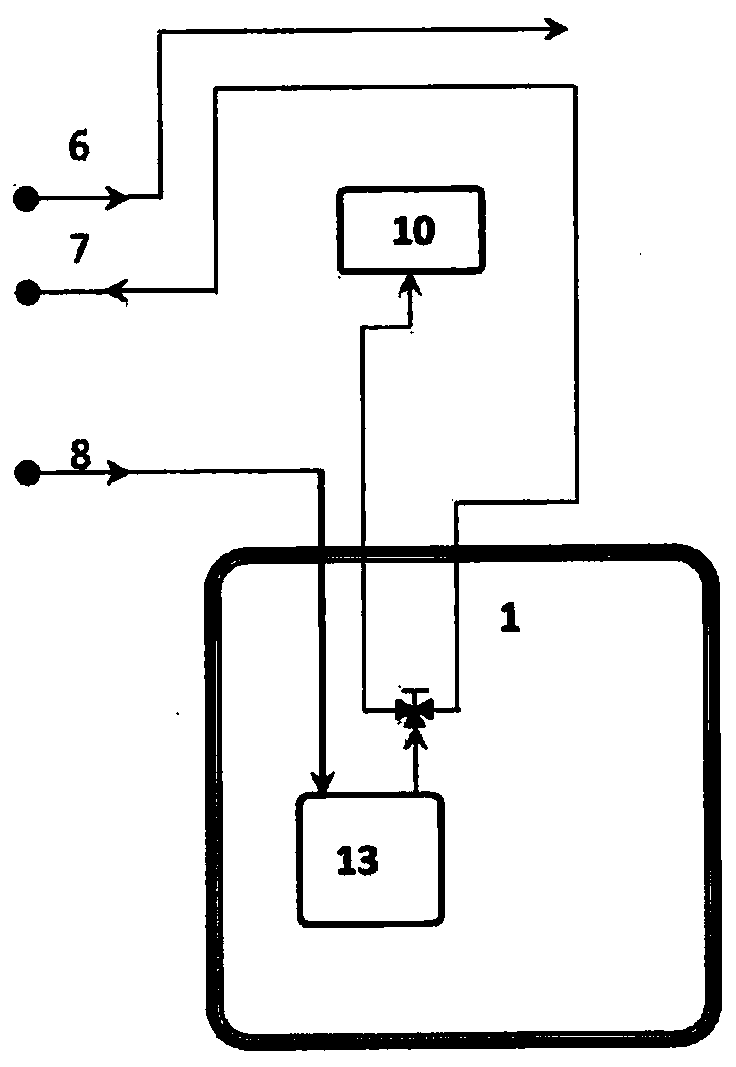

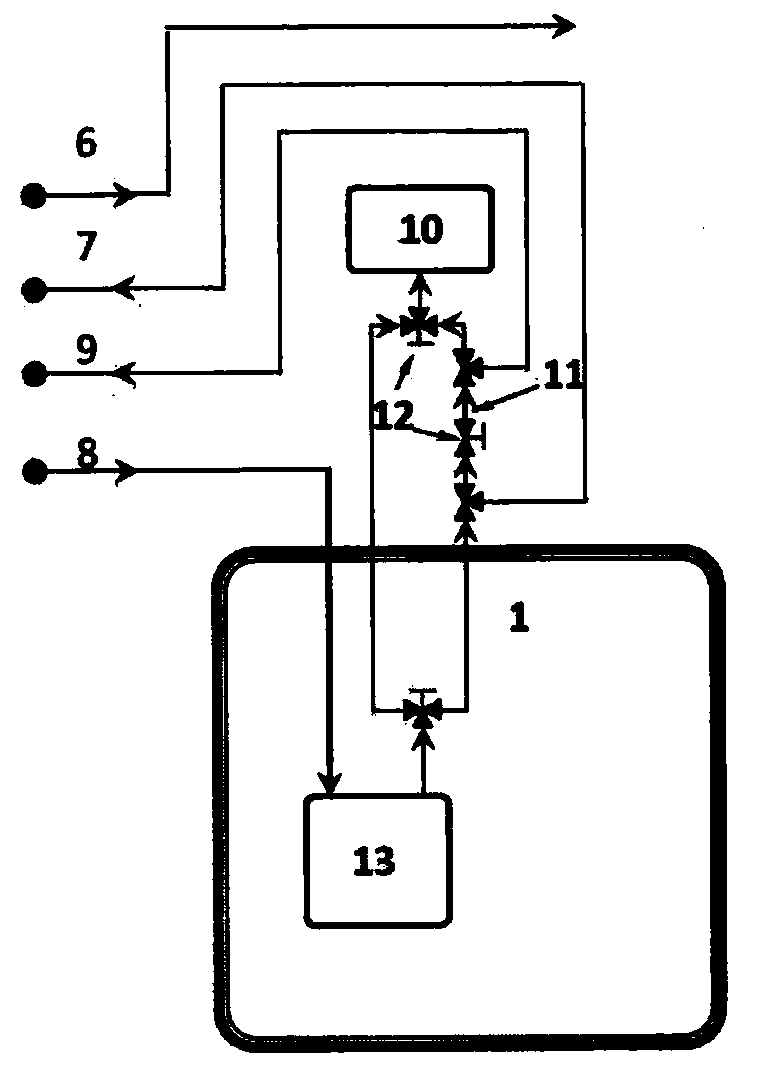

[0046] The basic design layout of the scheme of the present invention is as figure 1 As shown, the X-ray characterization equipment cabinet 1 is connected to the vacuum pipeline part 2 of the in-situ reaction pool according to the original design. In the original equipment, only the vacuum pipeline part 2 of the in-situ reaction cell is slightly modified to provide mass spectrometer sampling, while the radiation protection design of the X-ray characterization equipment cabinet 1 is not modified in any way. The original equipment area connects with XRD and the gas circuit centralized interface 3 (total four) and the upper layer 4 of the X-ray equipment in-situ pool reaction control and gas composition characterization workstation (reactor gas mixture switching and pressure control panel, operation interface display) and X The lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com