A kind of preparation method of hydrate core in permafrost zone

A production method and hydrate technology, which is applied in the field of natural gas hydrate reservoir simulation experiments, can solve the problems of long test period, accelerate hydrate formation, shorten the preparation period, etc., and achieve the effect of shortening the test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be described in detail below in combination with specific examples, so that those skilled in the art can better understand the technical solution in the present application.

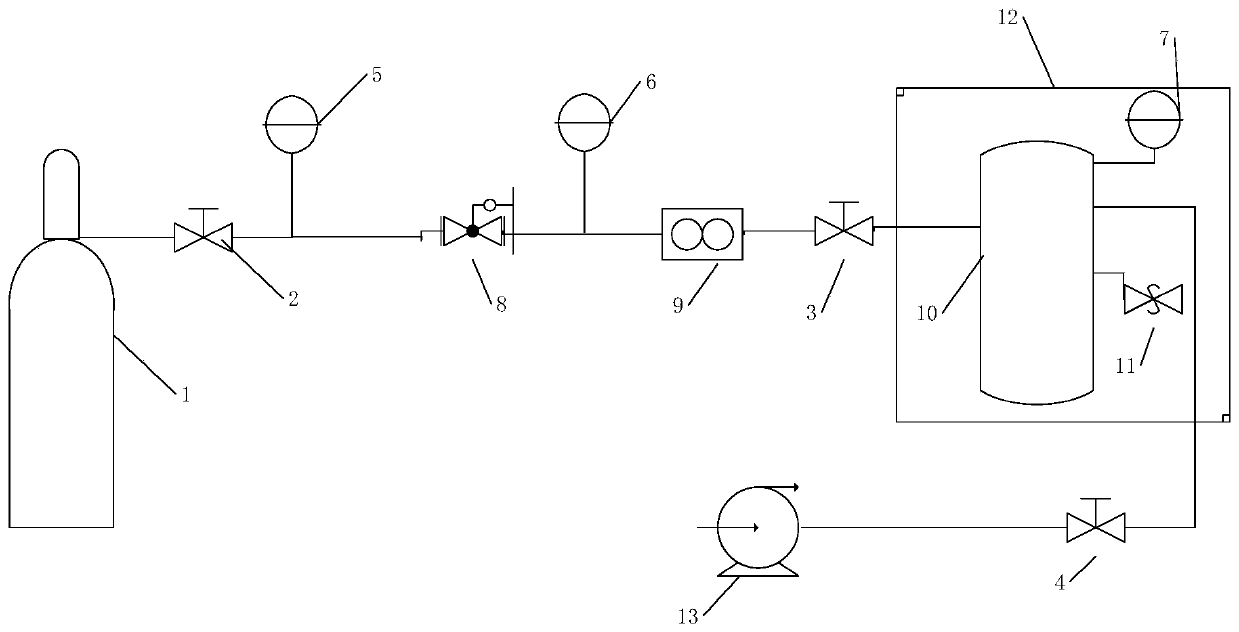

[0011] The hydrate synthesis device of the present invention is closely connected with the methane cylinder 1, the pressure reducing valve 8, the gas flow meter 9, the autoclave inlet valve 3, the autoclave 10, the vacuum pump 13, and the autoclave 10 is placed in the cold storage 12 by pipelines. According to the current relatively detailed exploration data, the hydrate formation cores in the Mount Elbert area on the northern slope of Alaska are simulated. The cores taken from the actual formations have a porosity of 35.6%, a uniaxial compressive strength of 4MPa, and a density of 1.86g / cm3. According to the target Prepare the core skeleton. The raw materials used are mainly quartz sand, illite, chlorite and cement. The 80-120 mesh and 120-200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com