Environment-friendly tail gas filter with tail gas discharge resistance adjusting function

An exhaust gas filter, an environmentally friendly technology, applied in the direction of gas chambers, exhaust treatment, exhaust devices, etc., can solve the problems of ineffective filtering of black smoke particles, noise pollution, hidden safety hazards, etc., to improve the effect of exhaust gas purification, solve The effect of large discharge resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

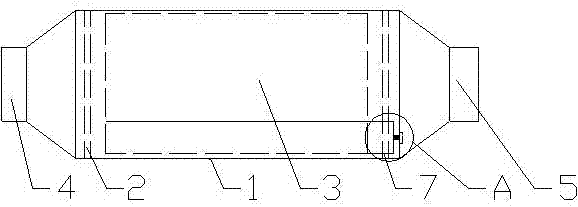

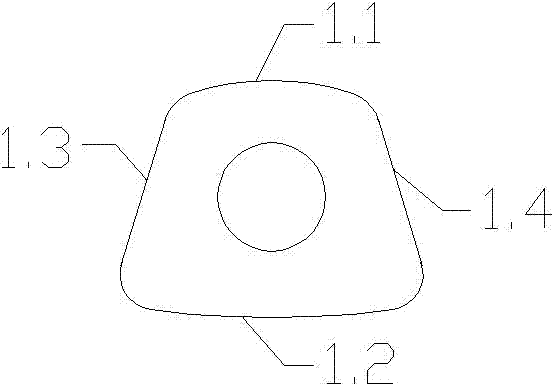

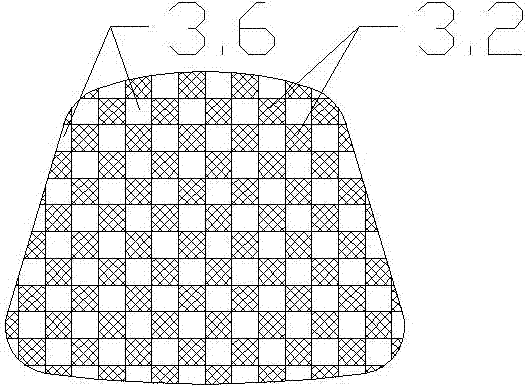

[0042] see Figure 1-6 , the present invention relates to an environment-friendly exhaust gas filter for adjusting exhaust gas resistance, which includes a filter box 1, a first filter screen 2, a ceramic honeycomb carrier 3 and a second filter screen 7, the left end of the filter box 1 is an exhaust gas inlet 4, and the right end It is the exhaust gas outlet 5, the first filter screen 2, the ceramic honeycomb carrier 3 and the second filter screen 7 are arranged in the filter box 1, the first filter screen 2 is close to the exhaust gas inlet 4, and the second filter screen 7 is close to the exhaust gas outlet , the filter box 1 includes a first arc side 1.1, a second arc side 1.2, a first hypotenuse 1.3 and a second hypotenuse 1.4, the first arc side 1.1, the second hypotenuse 1.4, the second The circular arc edge 1.2 and the first hypotenuse edge 1.3 are connected end to end in sequence, and the joints adopt a rounded corner transition. The shape of the ceramic honeycomb car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com