Waterborne impregnated resin, waterborne polyurethane superfine fiber synthetic leather and preparation method of waterborne polyurethane superfine fiber synthetic leather

A technology of water-based polyurethane and impregnated resin, which is applied in the direction of textiles and papermaking, which can solve the problems of insufficient and increase the flexibility of leather, achieve the effect of fine cell structure, reduce environmental pollution, and increase the release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation steps of the water-based microfiber synthetic leather of the present embodiment are as follows:

[0033] Preparation of water-based impregnating resin:

[0034] Table 1

[0035]

[0036]

[0037] Mix the raw materials in Table 1 evenly to prepare a water-based impregnating resin with a viscosity of about 5000mPa·S@25°C.

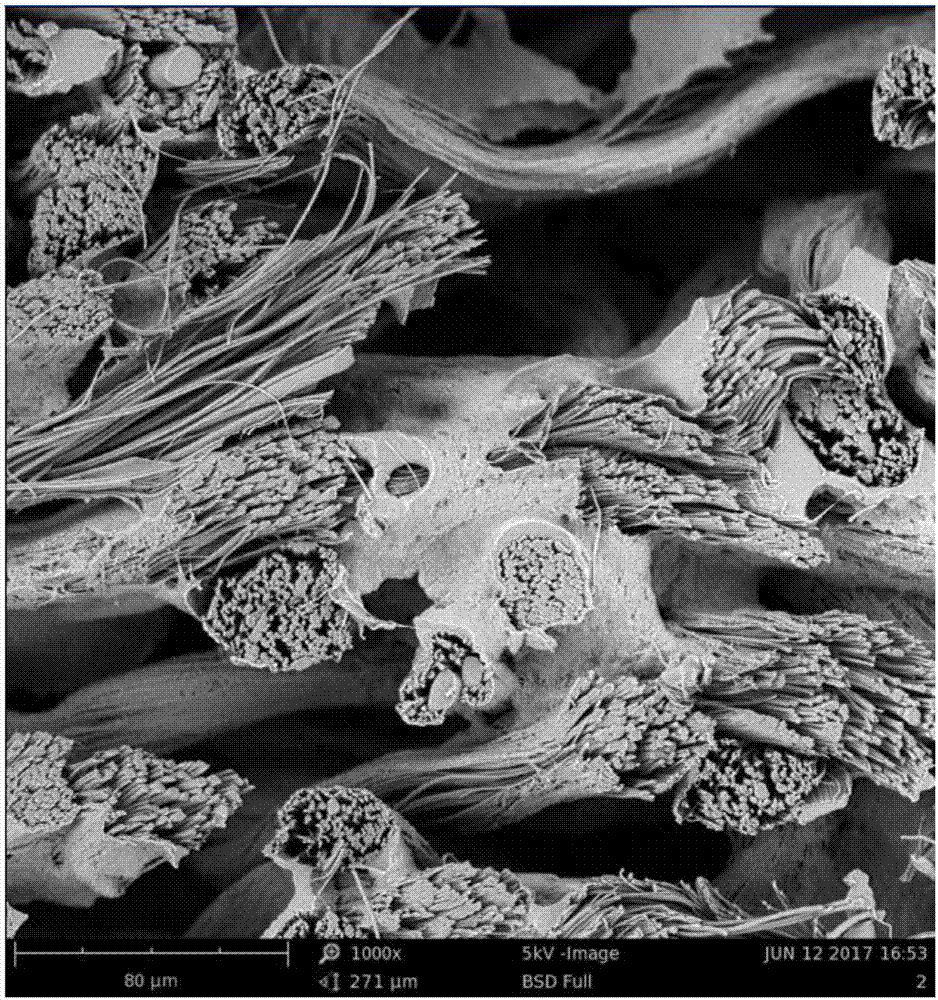

[0038] Preparation of primary base cloth:

[0039] Impregnate the island-in-the-sea non-woven fabric in the water-based impregnating resin, control the liquid content to 100%, scrape off the surface resin with a scraper, and then dry it in an oven at 90°C to obtain an impregnated base cloth; put the impregnated base cloth into the In the measuring process, use 75°C toluene to reduce the weight for 2 hours, and then use 105°C water to wash for 1 hour to wash away the residual toluene and dissolved soluble polymers, and dry the base cloth after the weight reduction is completed on a 120°C expansion drying equipment Dry to obtain ...

Embodiment 2

[0044] Preparation of water-based impregnating resin:

[0045] Table 2

[0046]

[0047] Mix the raw materials in Table 2 evenly to prepare a water-based impregnating resin with a viscosity of about 8000mPa·S@25°C.

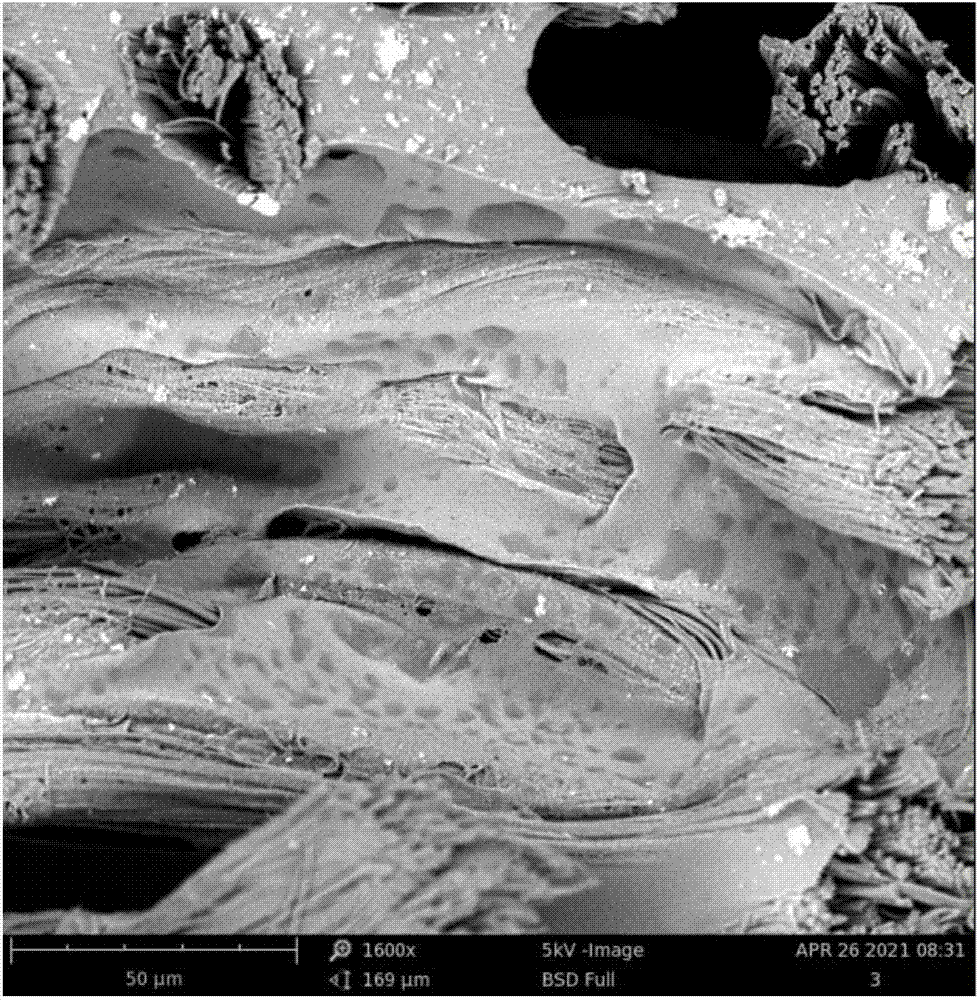

[0048] Preparation of primary base cloth:

[0049] Impregnate the island-in-the-sea non-woven fabric in the water-based impregnating resin, control the liquid content to 100%, scrape off the surface resin with a scraper, and then dry it in an oven at 90°C to obtain an impregnated base cloth; put the impregnated base cloth into the In the measuring process, use 85°C toluene to reduce the weight for 3 hours, wash with 100°C water for 2 hours to remove residual toluene and dissolved soluble polymers, and dry the base fabric after weight reduction on a 130°C expansion drying equipment. Prepare the original base cloth.

[0050] The water-based polyurethane microfiber synthetic leather can be obtained by dyeing, oiling, buffing and veneering the raw base cloth acc...

Embodiment 3

[0054] The preparation steps of the water-based microfiber synthetic leather of the present embodiment are as follows:

[0055] Preparation of water-based impregnating resin:

[0056] table 3

[0057]

[0058]Mix the raw materials in Table 3 evenly to prepare a water-based impregnating resin with a viscosity of about 3000mPa·S@25°C.

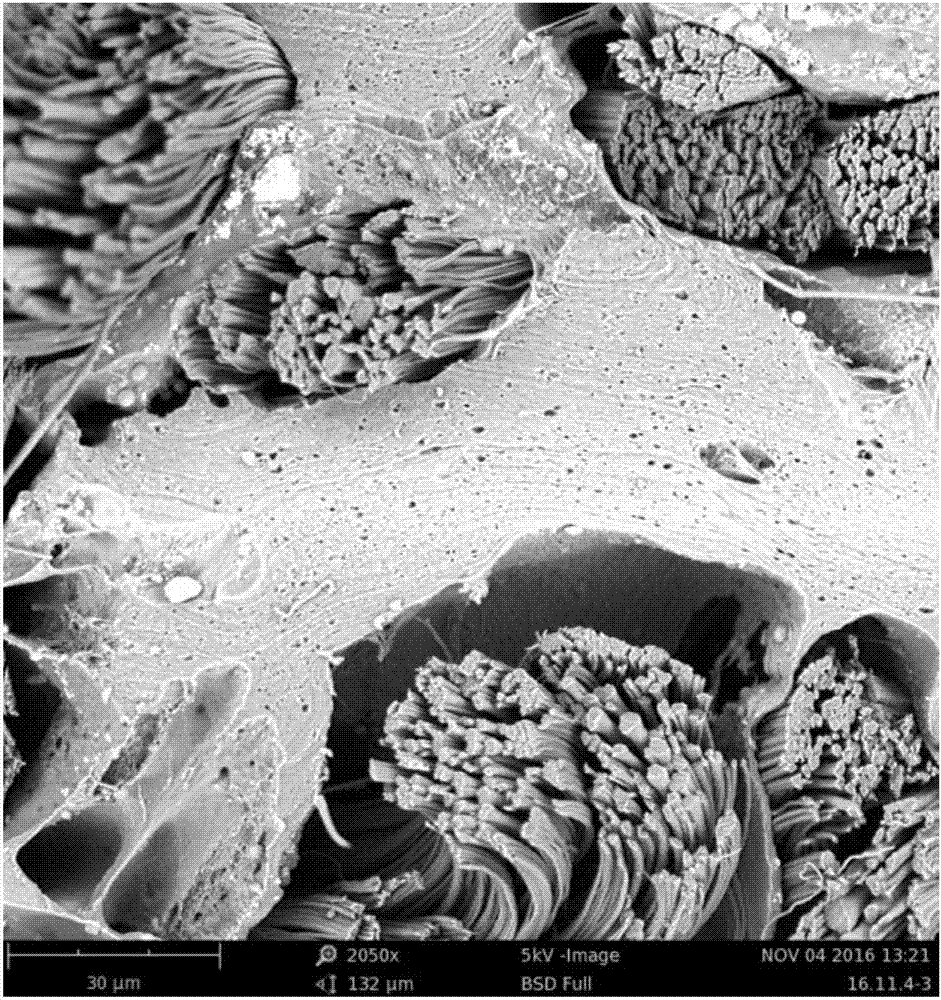

[0059] Preparation of primary base cloth:

[0060] Impregnate the island-in-the-sea non-woven fabric in the water-based impregnating resin, control the liquid content to 100%, scrape off the surface resin with a scraper, and then dry it in an oven at 90°C to obtain an impregnated base cloth; put the impregnated base cloth into the In the measuring process, reduce the weight with 90°C toluene for 1 hour, then wash with 110°C water for 0.5 hours to remove residual toluene and dissolved soluble polymers, and dry the base fabric after weight reduction on a 110°C expansion drying equipment , to produce primary base cloth.

[0061] The water-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com