System and method for treating waste pickling liquor and sludge in wire rope factories

A technology for pickling waste liquid and steel wire rope, applied in the field of environmental treatment, can solve the problems of secondary pollution and high treatment costs, and achieve the effects of preventing leakage, ensuring safety, and achieving reduction in quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

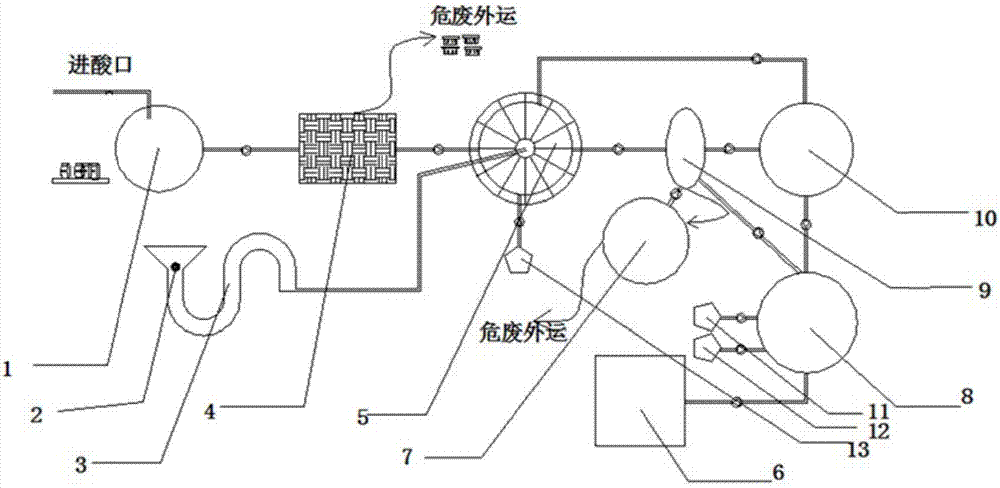

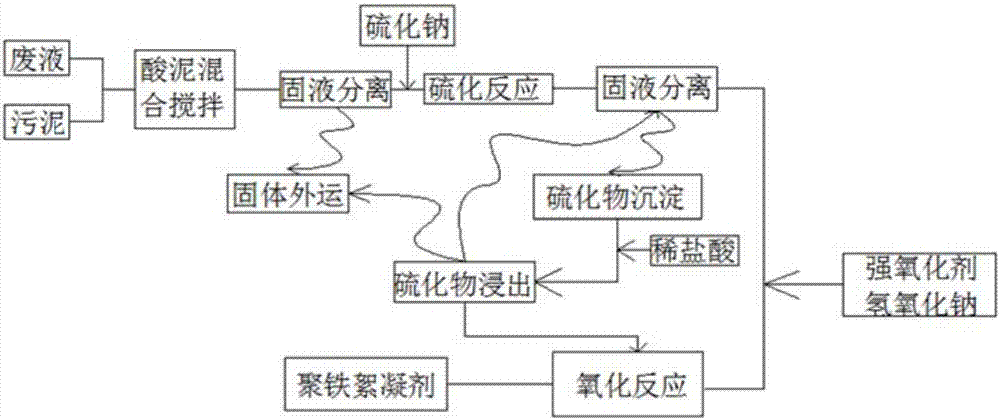

[0038] like figure 1 , figure 2 As shown, a system for treating pickling waste liquid and sludge in a steel wire rope factory can reduce sulfide sediment leaching devices without requiring sludge production and reducing equipment operation processes. The system includes acid mud mixing device 1, vacuum filtration device 4, lead-zinc waste liquid sodium sulfide treatment device 5, ferric chloride flocculant storage device 6, polyferric chloride flocculant preparation device 8, industrial centrifuge 9, vulcanization reaction Treatment effect safety device 10, the acid mud mixing device 1, vacuum filtration device 4, lead-zinc waste liquid sodium sulfide treatment device 5, industrial centrifuge 9, sulfidation reaction treatment effect safety device 10, polyferric chloride flocculant The preparation device 8 and the polyferric chloride flocculant storage device 6 are sequentially connected through pipelines, and a reflux device is provided between the lead-zinc waste liquid sod...

Embodiment 2

[0061] like figure 1 , 2 As shown, the sulfide precipitate separated from the industrial centrifuge still contains a large amount of ferrous ions. When the maximum efficiency of ferrous ions is required to prepare polyferric chloride flocculant and sludge reduction is required, it is necessary to increase Sulfide sediment leaching device 7 utilizes the dilute hydrochloric acid solution of pH=1 to effectively leach ferrous ions and lead-zinc ions co-precipitated with lead-zinc, thereby reducing the content of ferrous ions and lead-zinc ions in the sludge and achieving heavy purpose. Continue to detect the concentration of lead and zinc in the leaching solution. When the concentration of lead and zinc in the leaching solution reaches the requirements of HG / T 4672-2014 "Water Treatment Agent Polyferric Chloride", when Pb<20ppm and Zn<1000ppm, use special pumps to pump to polychloride In the iron flocculant preparation device, the polyferric chloride flocculant is prepared. If ...

Embodiment 3

[0074] like figure 1 , figure 2 As shown, in the case of requiring the reduction of sludge production, the sulfidation sediment leaching device should be added.

[0075] A system for treating pickling waste liquid and sludge in a steel wire rope factory, including an acid mud mixing device 1, a vacuum filtration device 4, a lead-zinc waste liquid sodium sulfide treatment device 5, a ferric chloride flocculant storage device 6, and a sulfurized sediment Leaching device 7, polyferric chloride flocculant preparation device 8, industrial centrifuge 9, vulcanization reaction treatment effect safety device 10, the acid mud mixing device 1, vacuum filtration device 4, lead-zinc waste liquid sodium sulfide treatment device 5. Industrial centrifuge 9, vulcanization reaction treatment effect safety device 10, polyferric chloride flocculant preparation device 8, polyferric chloride flocculant storage device 6 are sequentially connected through pipelines, the lead-zinc waste liquid sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com