Rotor and dispersion machine for dispersing materials

A disperser and rotor technology, applied in grain processing and other directions, can solve the problems of dispersion failure, poor equipment structure optimization, increased energy consumption and material consumption, etc., to reduce the possibility of secondary agglomeration, uniform and stable material particle size, and production. The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

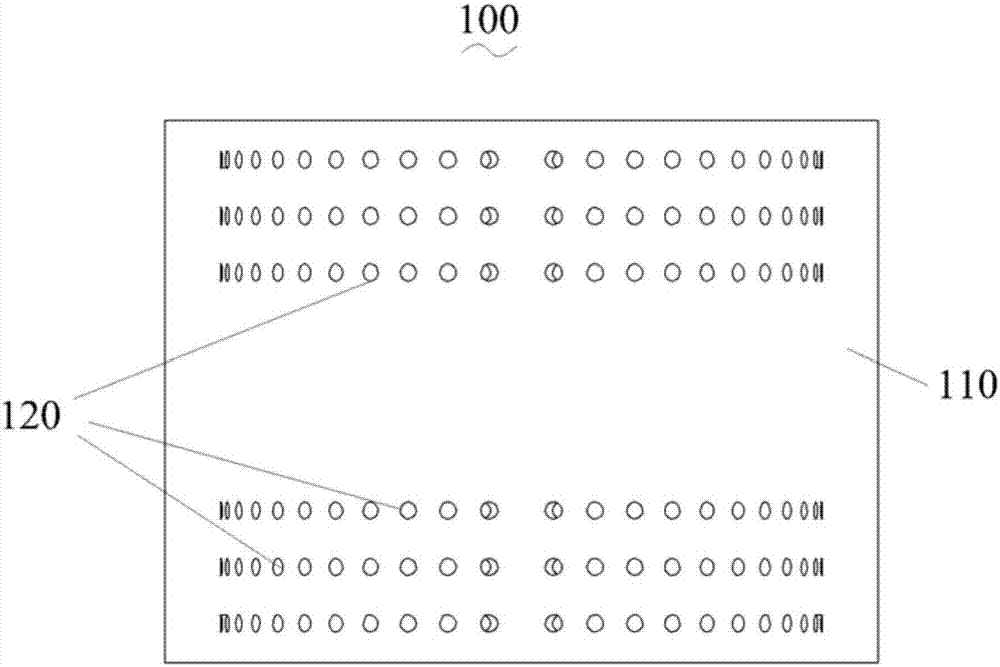

[0049] refer to figure 1 and figure 2 , in this embodiment, a rotor 100 for dispersing materials is proposed, and the purpose of dispersing materials is achieved by rotating the rotor 100 at a high speed.

[0050] The rotor 100 is a rotating body structure.

[0051] The surface formed by a plane curve or straight line rotating around a fixed line in its plane is called a surface of revolution, and the geometry formed by a closed surface of revolution is a solid of revolution. Wherein, the fixed line is called the center line of the rotating body.

[0052] In this embodiment, the rotor 100 is configured in a cylindrical shape.

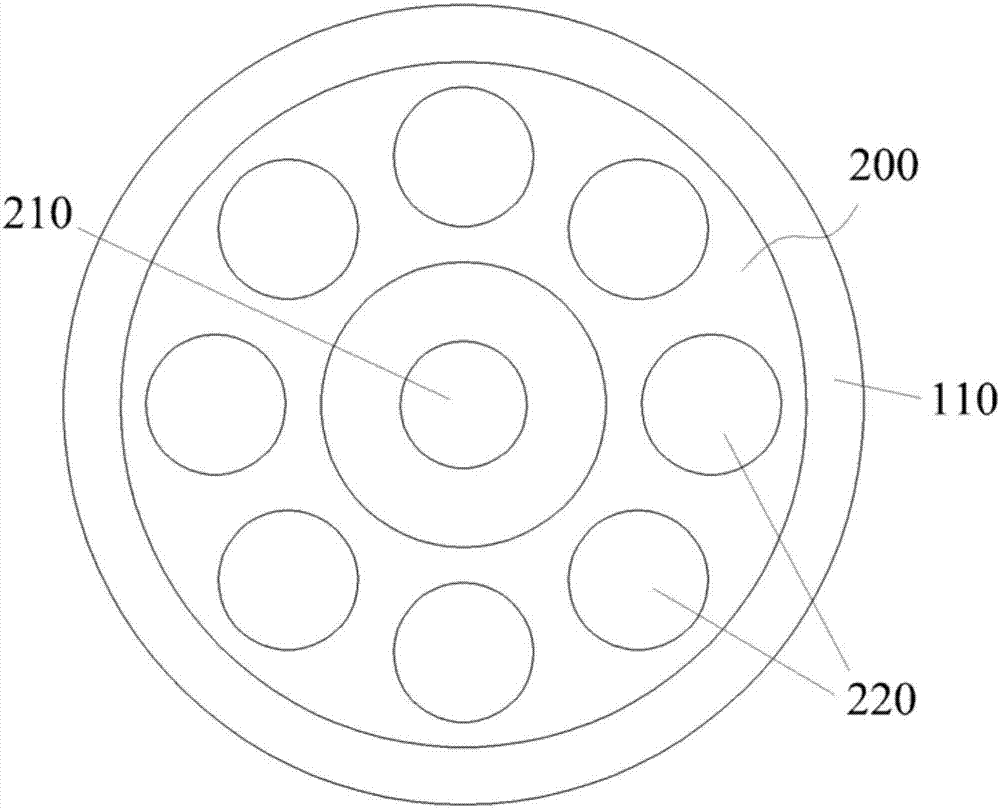

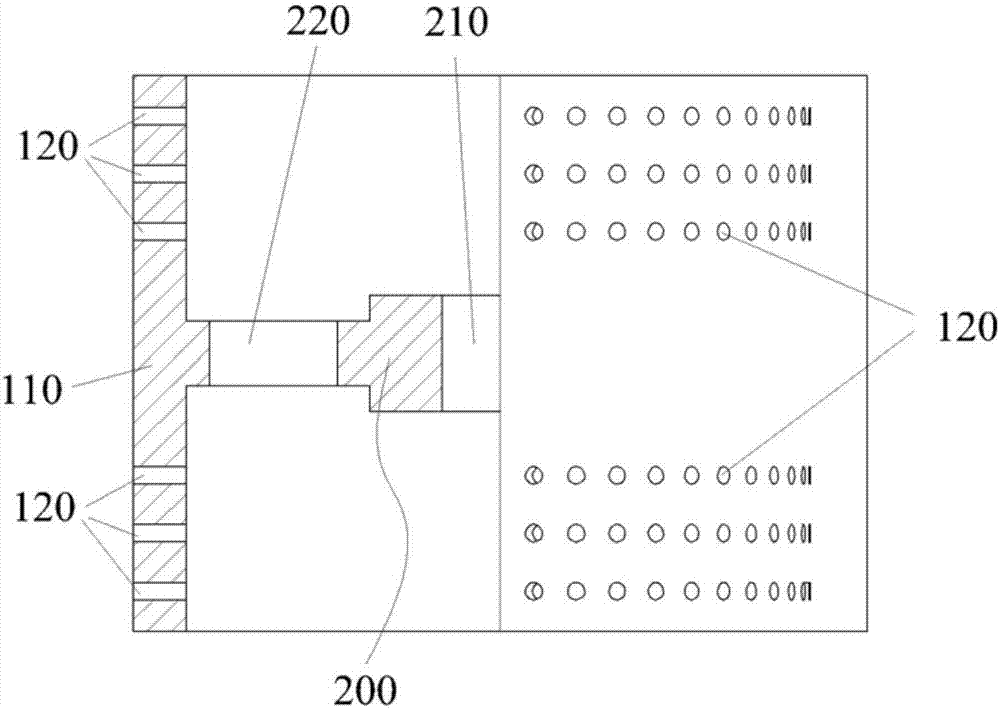

[0053] Such as image 3As shown, the rotor 100 includes an outer wall 110, wherein the interior of the rotor 100 is a hollow structure, so that the interior of the rotor 100 can be used to accommodate materials to be dispersed.

[0054] Since the rotor 100 is cylindrical, the outer surface of the outer wall 110 is a cylindrical surface. Meanwhile...

Embodiment 2

[0071] In this embodiment, a disperser is proposed, which includes a high-speed motor and a rotor 100 for dispersing materials.

[0072] High-speed motors generally refer to motors whose speed exceeds 10000r / min. Due to the high speed of the high-speed motor, the power density of the motor is high. At the same time, the height motor has a small moment of inertia and fast dynamic response.

[0073] In this embodiment, the high-speed motor can be selected with a rotation speed of 15000 r / min.

[0074] Such as figure 1 , figure 2 and image 3 As shown, wherein, the rotor 100 is a rotating body structure. In this embodiment, the rotor 100 is configured in a cylindrical shape.

[0075] The rotor 100 includes an outer wall 110 , wherein the interior of the rotor 100 is a hollow structure. Among them, the materials to be dispersed are stored in the hollow structure.

[0076] In order to disperse the material more evenly, the outer surface and the inner surface of the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com