Preparation and application of mercapto-modified metal-organic framework compound catalysts

A metal-organic framework and mercapto-modified technology, which is applied in the preparation of organic compounds, carbon-based compounds, organic compound/hydride/coordination complex catalysts, etc., can solve problems affecting the photocatalytic performance of noble metal/MOF composite materials, etc. , to achieve good benzaldehyde selectivity, improve light absorption performance, and good conversion rate of benzyl alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] UiO-66(SH) 2 Specific preparation of photocatalyst

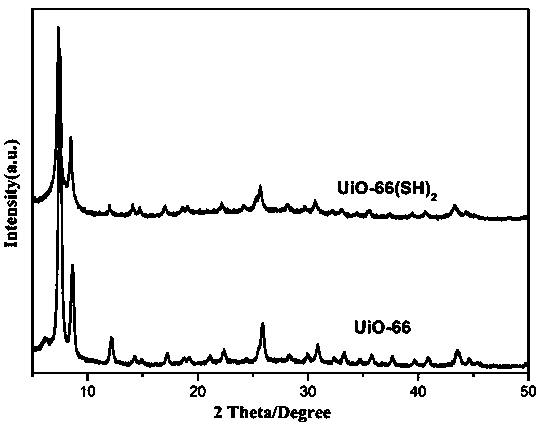

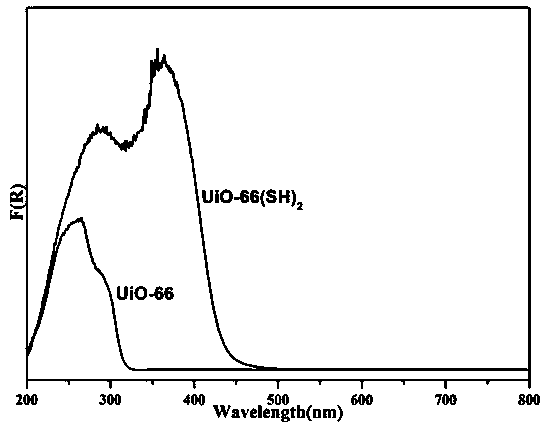

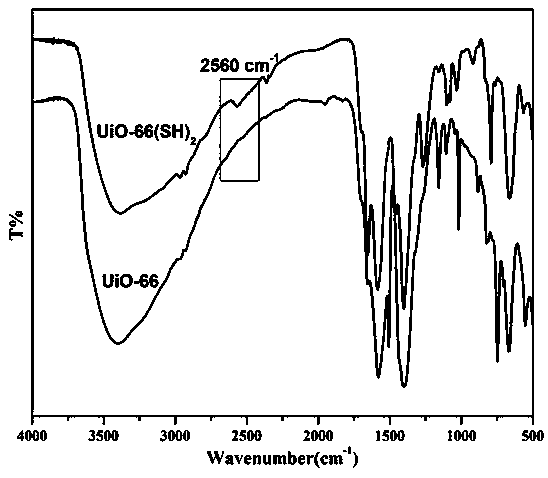

[0030] Weigh zirconium tetrachloride and 2,5-dimercapto-1,4-terephthalic acid with a molar ratio of 1:1, dissolve them in 50 mL DMF, stir at room temperature until the solution is homogeneous and transparent, then transfer to a 100 mL high-pressure In the reactor, it was kept at 120 °C for 24 h. After the obtained sample was naturally cooled, it was heated and stirred with DMF at 60 °C for 2 h, and then the residual DMF was exchanged with dichloromethane, and the yellow powder UiO-66(SH) was obtained after vacuum drying at 100 °C for 12 h. 2 . figure 1 Demonstrate the UiO-66(SH) prepared by this method 2 XRD pattern with UiO-66, it can be seen that UiO-66(SH) 2 Has the same topology as UiO-66. figure 2 Demonstrated UiO-66(SH) 2 Compared with the DRS diagram of UiO-66, the modification of sulfhydryl group can successfully broaden the absorption band edge of UiO-66 from the ultraviolet region (320 nm) to the visi...

Embodiment 2

[0032] M / UiO-66(SH) 2 Preparation of (M=Au, Pd, Pt) Composite Photocatalytic Materials

[0033] First take by weighing the UiO-66 (SH) that embodiment 1 makes 2 100 mg of sample was ultrasonically dispersed in 40 mL of ethanol and water (v : v = 1:1) solution, and a certain volume of metal precursor (0.420 ml HAuCl 4 , 0.332 ml H 2 PdCl 4 or 0.530 ml H 2 PtCl 6 (both 10 mg / mL)) solution was added dropwise to the mixed solution. After stirring for 12 h, the obtained sample is M / UiO-66(SH) 2 (M=Au, Pd, Pt). Figure 4 Demonstrated UiO-66(SH) 2 and M / UiO-66(SH) 2 The XRD pattern. Figure 5 Showcasing the M / UiO-66(SH) 2 It can be seen from the figure that the presence of metal particles was not observed in high-resolution transmission electron microscopy (HRTEM) and scanning transmission electron microscopy (STEM), but the uniform distribution of noble metals was detected in the selected element scanning. Explain the preparation of M / UiO-66(SH) by using mercapto-anc...

Embodiment 3

[0035] UiO-66(SH) 2 Activity of Photocatalytic Selective Oxidation of Benzyl Alcohol at Room Temperature

[0036] Weigh 20 mg of the prepared catalyst sample with an analytical balance, and pipette 1.5 mL and 0.1 mmol of the reaction substrate in trifluorotoluene solution filled with saturated air and nitrogen respectively with a pipette gun, and place them together in a Pyrex glass tube. Connect a balloon filled with the corresponding gas at a pressure of 0.1 MPa to ensure the gas atmosphere. After ultrasonic dispersion, the sample was irradiated with xenon lamp to simulate visible light (λ≥ 420 nm) for 12 h, then centrifuged and the chemical components in the supernatant were detected by gas chromatography. The results are shown in Table 1, the overall conversion rate under nitrogen atmosphere is higher than that under atmospheric atmosphere. It can be seen from Nos. 2 and 3 that when there is –CH at the para-position of the benzene ring 3 and –OCH 3 When the power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com