Coal sample while-drilling fixed point collecting device

A collection device and drilling-while-drilling technology, applied to sampling devices and other directions, can solve problems such as visual errors, large errors, and lack of authenticity, and achieve the effect of reducing exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

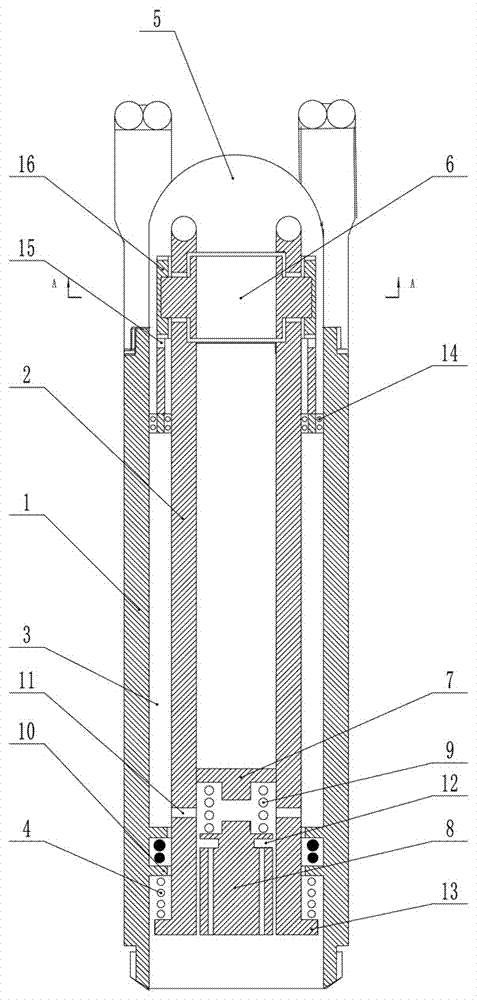

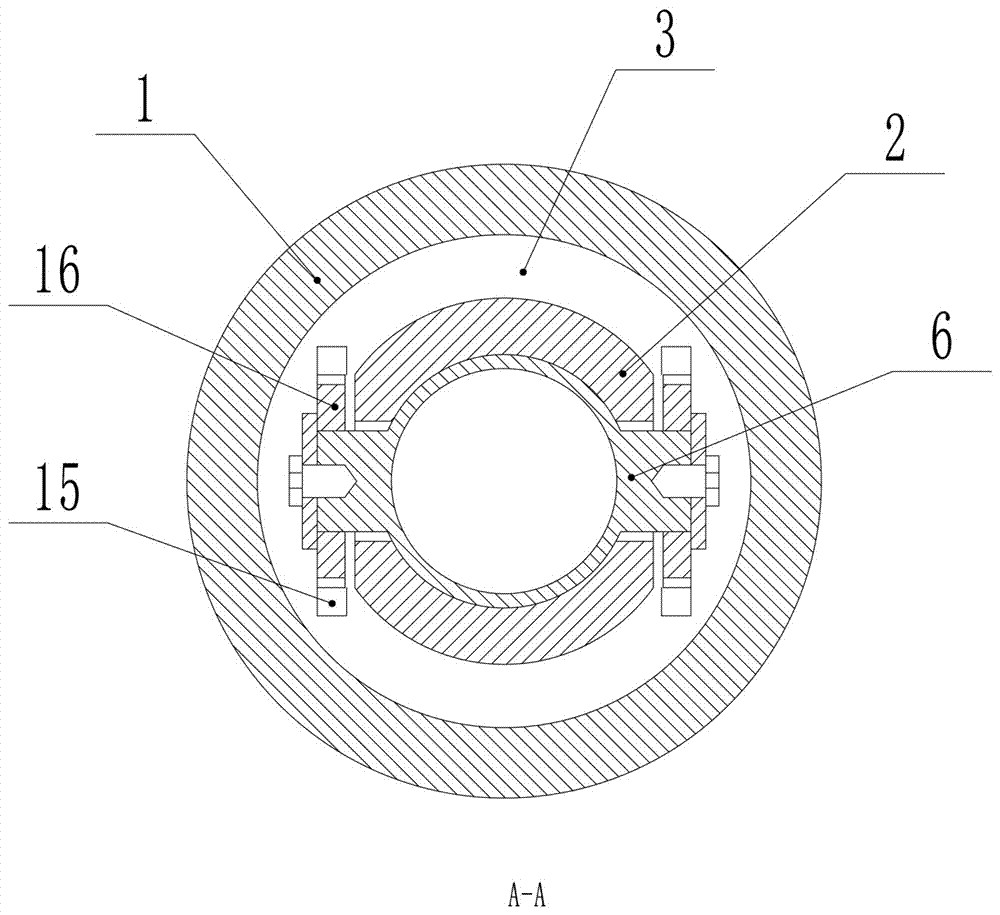

[0033] Such as Figure 1-Figure 3 As shown, a fixed-point collection device for coal samples while drilling includes a combined drill bit and a drill pipe. The drill pipe includes a cylindrical outer shell 1, a collection chamber 2 with only front openings, a pressure chamber 3, and a primary pressure valve. And secondary pressure spring 4.

[0034] The collection cavity 2 is coaxially arranged in the outer shell 1 and can reciprocate along the axial direction of the outer shell 1. The inner sides of the first and last ends of the outer shell 1 are provided with bosses 10, and the bosses 10 A sealing ring is installed inside, the collection cavity 2 is slidingly fitted with the sealing ring, a rib 13 is arranged at the tail end of the collection cavity 2, and the two ends of the secondary pressure spring 4 are respectively arranged in the collection cavity The rib 13 of 2 and the boss 10 at the tail end of the outer shell 1 form a high-pressure sealing structure at the tail e...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that the pressure chamber is an independent structure, and the pressure chamber is located outside the outer casing or between the outer casing and the collection chamber, the purpose of which is to reduce the impact on The sealing requirements for the cooperation between the outer casing and the collection cavity require an additional completely sealed structure.

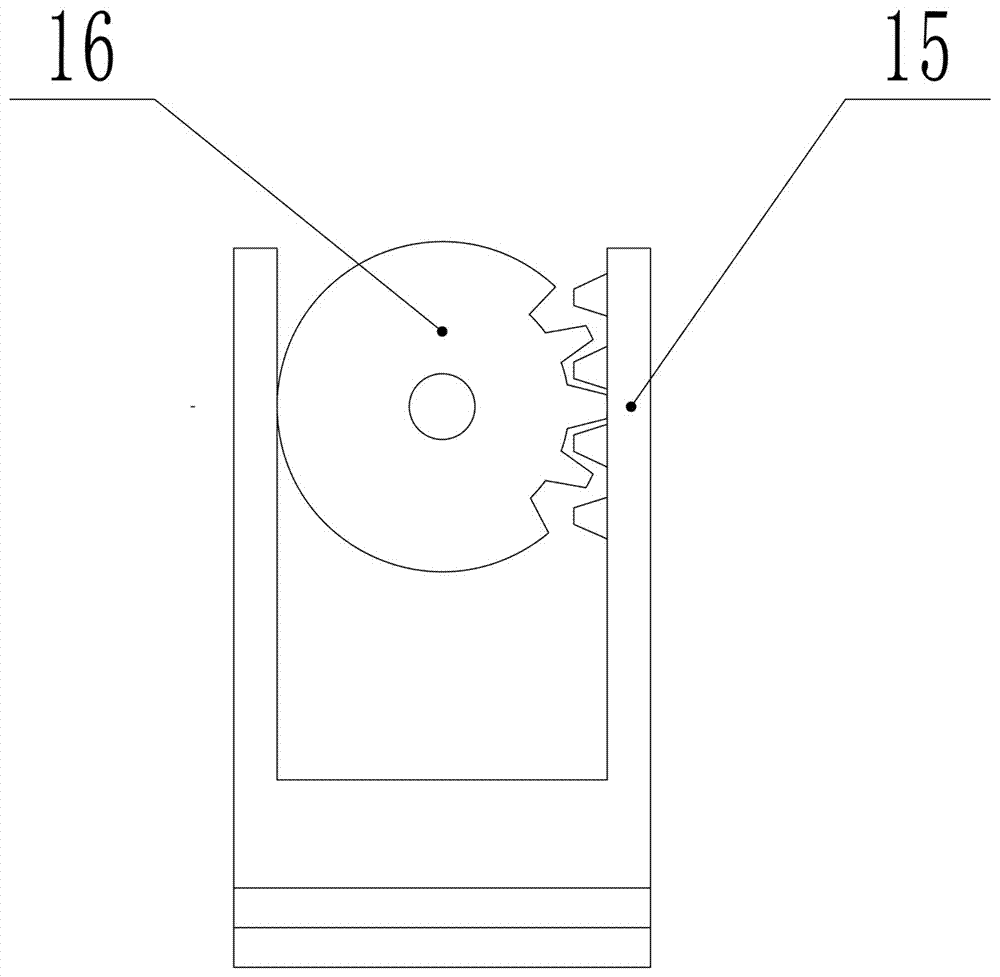

[0053] Further, the combined drill bit includes a drilling bit, the drilling bit includes a left half and a right half, the left half is hinged on the left side of the outer casing, and the right half is hinged on the The right side of the outer casing, the front end of the collection cavity is respectively hinged or abutted against the middle part of the front half and the middle part of the right half, and the left half and the middle part of the right half are docked to form the The drill bit described above has a two-petal structure. After openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com