Surface-acoustic-wave-based micro-position sensor

A surface acoustic wave and sensor technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems that micro position sensors have not been reported, and achieve accurate and reliable detection results, high sensitivity, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

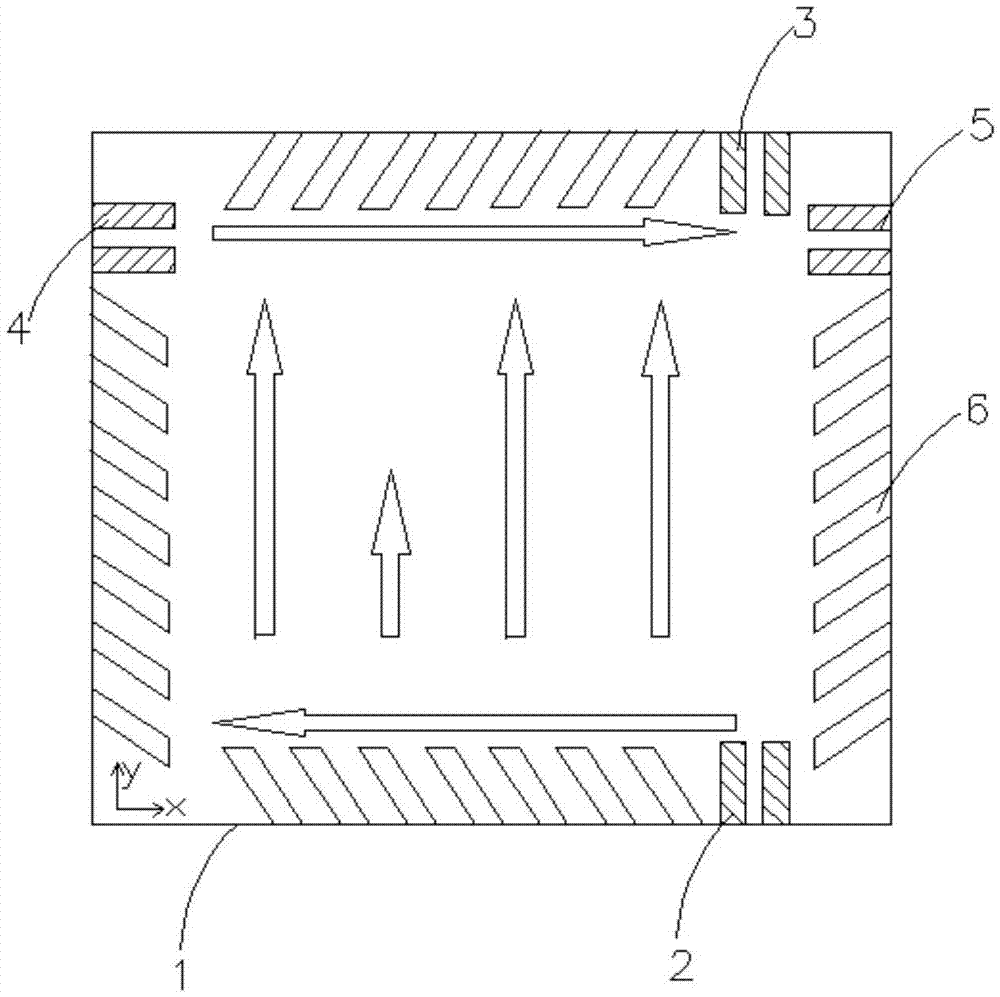

[0021] Such as figure 1 As shown, the micro-position sensor based on the surface acoustic wave includes a square piezoelectric substrate 1, and the inner walls of the two sides of the piezoelectric substrate 1 in the vertical direction are correspondingly provided with a first surface acoustic wave emitter 2 and a second surface acoustic wave emitter. The surface acoustic wave receiver 3 is provided with a second surface acoustic wave transmitter 4 and a second surface acoustic wave receiver 5 on the inner walls of the two sides of the piezoelectric substrate 1 in the horizontal direction. The surface acoustic wave transmitter 2, the first surface acoustic wave receiver 3, the second surface acoustic wave transmitter 4 and the second surface acousti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com