Adsorbed fabric singeing equipment

An adsorption and fabric technology, applied in the field of textile production, can solve the problems that the fiber is not cleaned, the erection effect cannot be controlled, and cannot be realized, and achieves excellent singeing effect, improved fiber treatment effect, and high-efficiency fiber hair removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

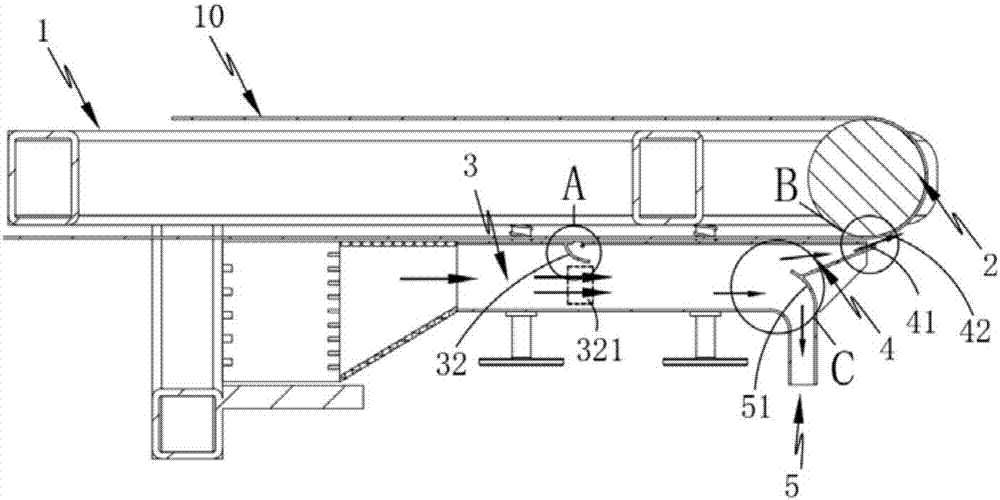

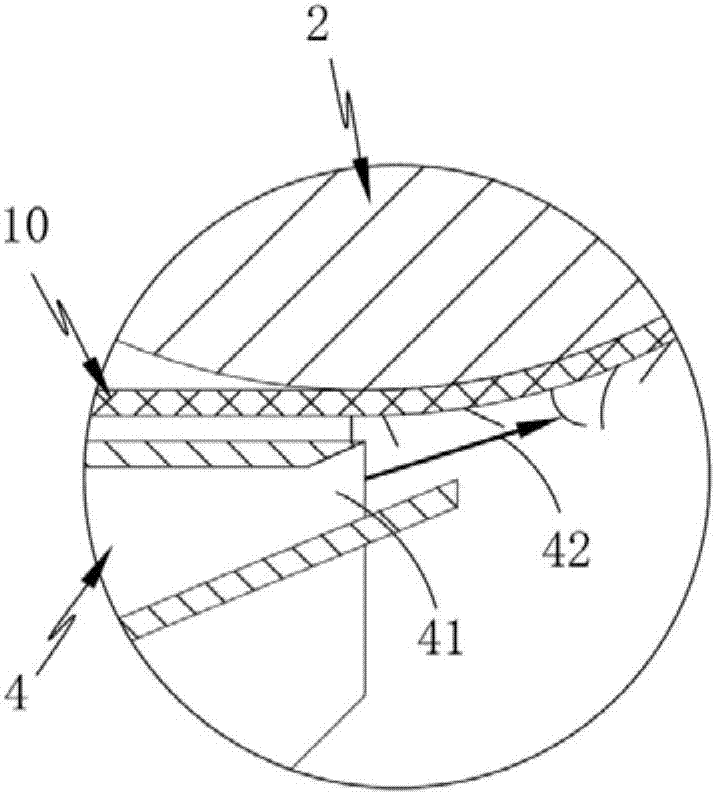

[0040] Such as figure 1 , 2 As shown in and 3, an adsorption-type cloth singeing device includes a support 1 and a cloth guide roller 2 that is rotatably mounted on the support 1 for conducting the cloth 10, and also includes:

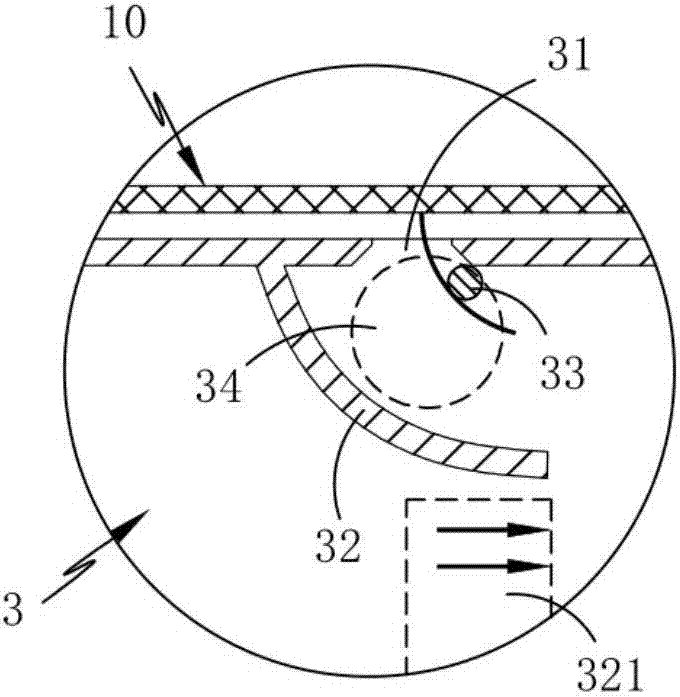

[0041] The airflow channel 3, the airflow channel 3 is located below the cloth 10, the airflow channel 3 includes an adsorption hole 31 set on its top, a baffle plate 32 fixedly arranged on one side of the adsorption hole 31, and a baffle plate 32 arranged on the adsorption hole 31 The heating wire 33 on the other side forms an airflow acceleration zone 321 between the baffle plate 32 and the opposite airflow passage wall, and the airflow flows along the airflow passage 3 and is formed at the adsorption hole 31 through the airflow acceleration zone 321 Negative pressure zone 34; during the transmission process of the cloth 10, the cloth 10 passes through the adsorption hole 31 continuously, and the fibers on the surface of the cloth 10 pass through th...

Embodiment 2

[0048] Such as Figure 5 and 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that it also includes a combing assembly 6 arranged on the support 1 and in contact with the upper surface of the cloth 10. The combing assembly 6 includes:

[0049] Combing roller brush 61, described carding roller brush 61 is rotated and arranged directly above the cloth 10, and its outer peripheral surface is provided with a number of combing teeth 611 for fluffing the surface fibers of the cloth 10; the combing teeth 611 are convexly arranged;

[0050] The transmission part 62, the carding roller brush 61 and the cloth guide roller 2 are connected through the transmission part 62, and between the spee...

Embodiment 3

[0055] Such as Figure 9 As shown, the same or corresponding components as in Embodiment 1 and Embodiment 2 adopt the corresponding reference numerals as in Embodiment 1 and Embodiment 2. For the sake of simplicity, only the differences from Embodiment 1 and Embodiment 2 are described below. point. The difference between this embodiment three and embodiment one and embodiment two is that: at least two adsorption holes 31 are arranged on the top of the airflow channel 3 along the conveying direction of the cloth 10; Adsorption holes 31 carry out fiber adsorption, and the amount of gas sucked into the fibers is limited, so the hair removal rate of the cloth 10 will decrease. However, a plurality of adsorption holes 31 are adopted, and the fibers pass through the plurality of adsorption holes 31 to improve the hair removal rate of the cloth 10. Simultaneously, when the fiber has reached the requirement of depilation, the adsorption hole 31 carries out a certain amount of adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com