Turnout gap intelligent monitoring system

An intelligent monitoring and gap technology, which is applied in the direction of railway signal and safety, can solve the problems of unsafe manual inspection, affecting the safety of railway traffic, and hidden dangers of switch machine operation, so as to improve work efficiency and safety, and achieve a huge safety economy benefit, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

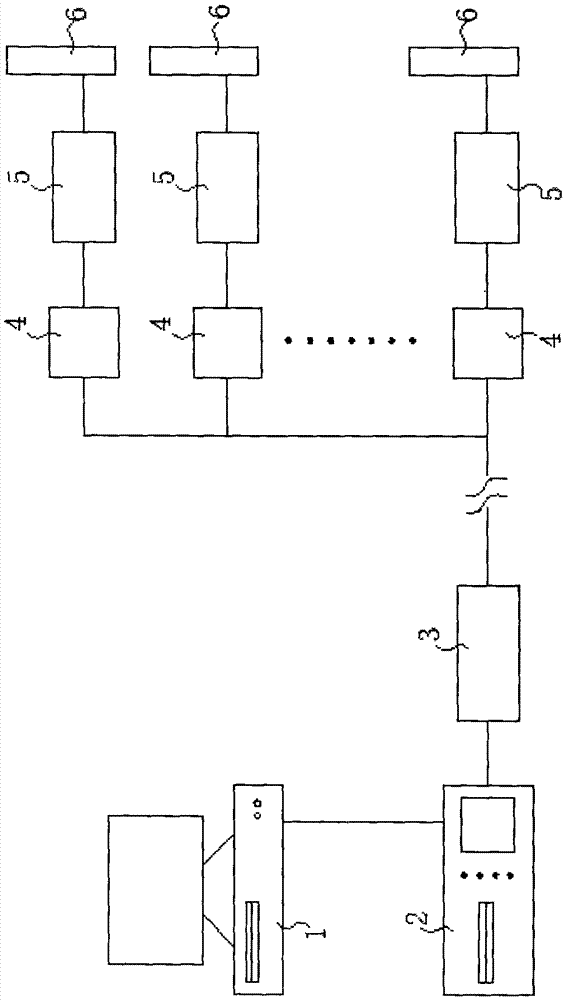

[0029] Such as figure 1 As shown, the switch gap intelligent monitoring system of the present invention includes a microcomputer 1 and several gap intelligent hosts 2 communicated with the microcomputer 1, and each of the gap intelligent hosts is connected to several monitoring branches through a distribution board 3. The monitoring branch includes a gap intelligent extension 5 and a gap detector 6, and the gap detector 6 is arranged on the switch machine. The breach detector 6 is connected with the breach intelligent extension 5 , and the breach intelligent extension 5 is connected with the breach intelligent host 2 . Here, the number of gap intelligent extensions 5 and gap detectors 6 depends on the number of switch machines to be monitored. One switch machine corresponds to one gap intelligent extension 5 and a group of gap detectors 6 . A group of gap detectors 6 is arranged on each switch machine, and the group of gap detectors 6 is connected with a gap intelligent exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com