Clamp structure

A fixture and clamping technology, which is applied in the field of fixture structure that is convenient for processing, can solve problems such as complicated operation, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

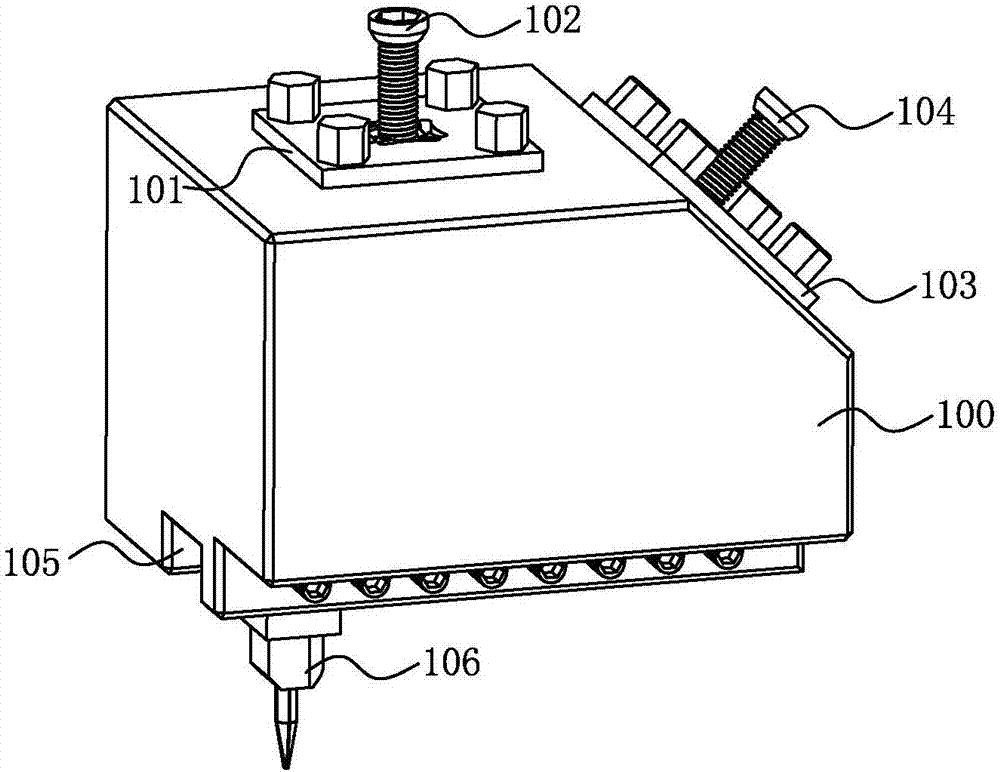

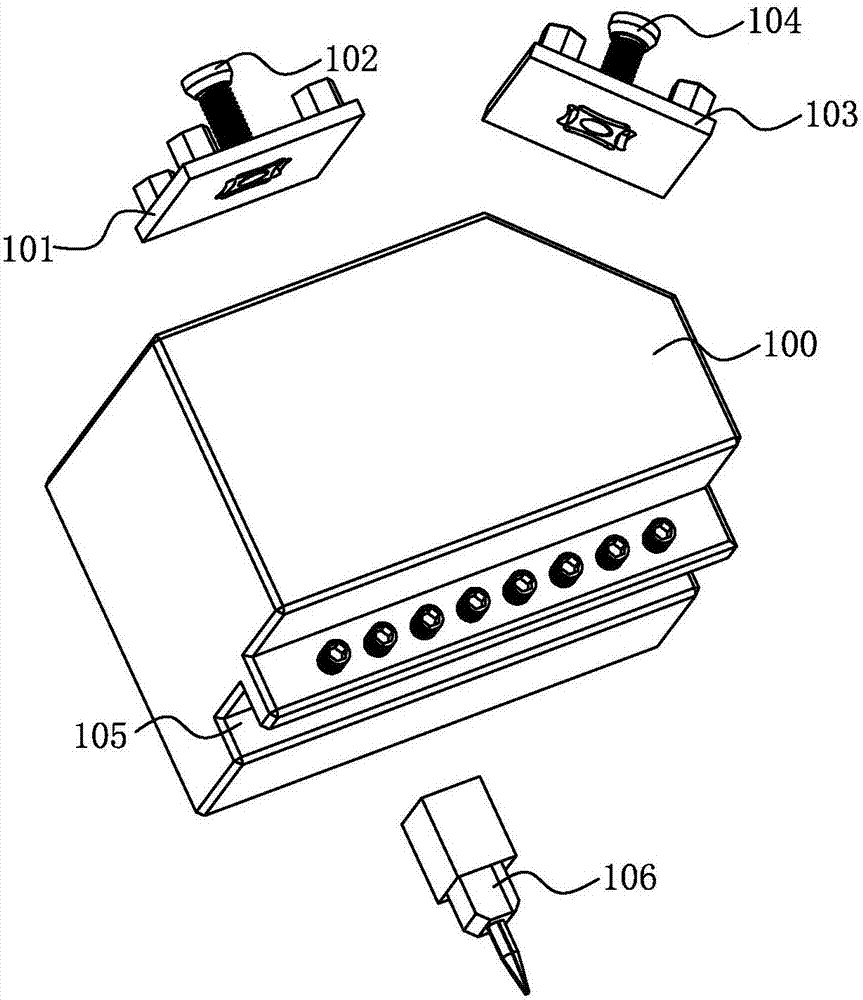

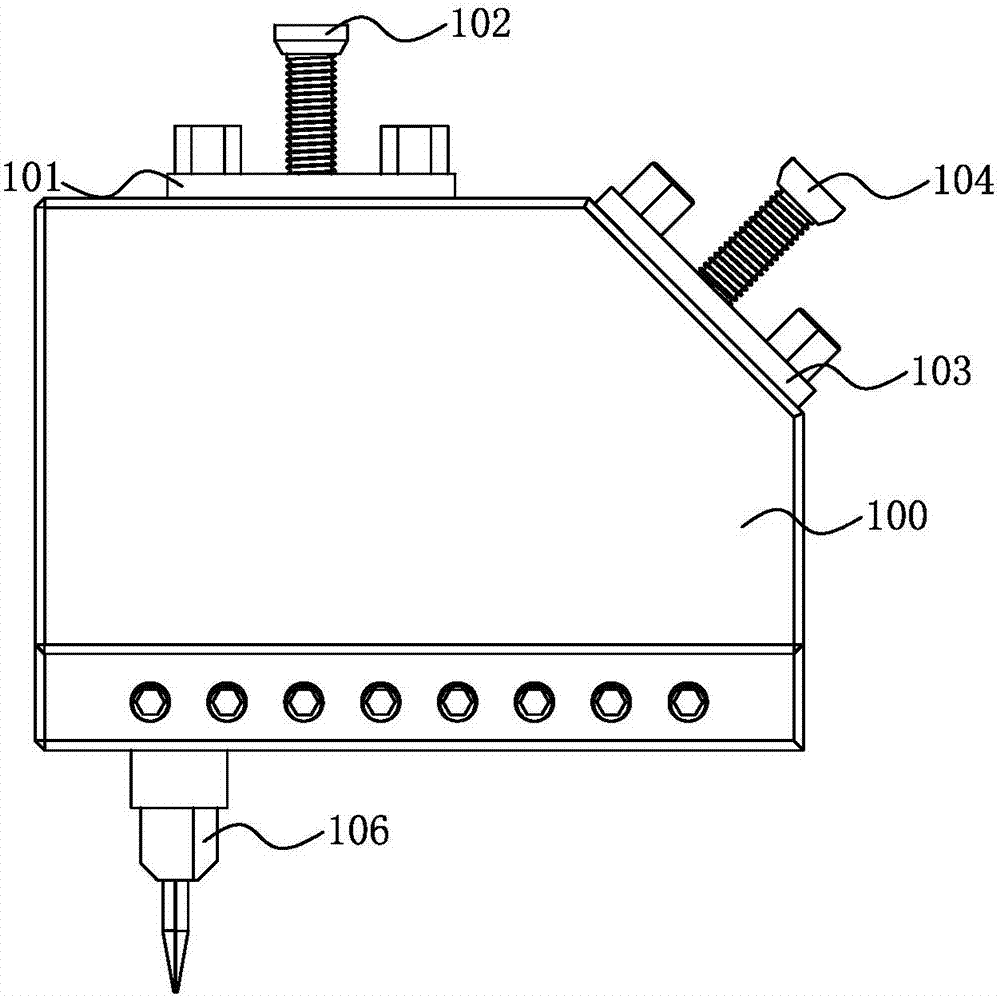

[0017] see figure 1 , 2 , figure 1 Illustrated as a schematic diagram of the assembly structure of a preferred embodiment of a fixture structure of the present invention, figure 2 It is a schematic diagram showing an exploded structure of a preferred embodiment of a fixture structure of the present invention.

[0018] In order to achieve the above object, the fixture structure provided by the present invention includes:

[0019] The fixture base 100 has a first plane, a second plane and a third plane on it, the first plane is parallel to the third plane, there is an angle between the first plane and the second plane, and the first plane is parallel to the third plane. The angle between the plane and the second plane is 135 degrees;

[0020] The first clamping part includes a first clamping gasket 101 and a first base screw 102, the first clamping gasket 101 is fixed on the first plane, and one end of the first base screw 102 is fixed on The other end of the first clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com