Height-adjustable thread hanging frame

An adjustable and wire hanger technology, applied in the field of wire hangers, can solve the problems of inconvenient movement of wire hangers, fixed wire rods, easy poking of wire rods, etc., and achieves simple structure, processing and manufacturing Easy, easy-to-move effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

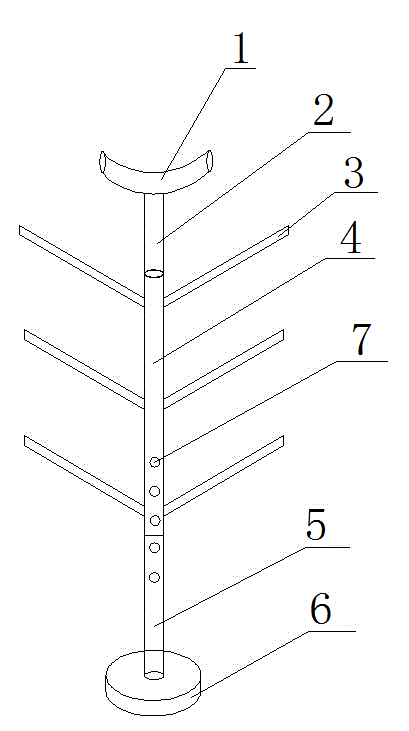

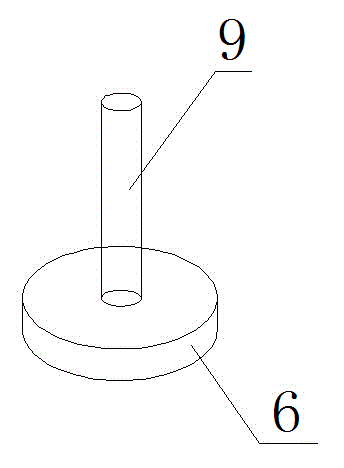

[0019] Such as figure 1 As shown, a height-adjustable wire hanger includes a base 6, a vertically arranged center rod and a wire hanger 3 obliquely arranged on the center rod.

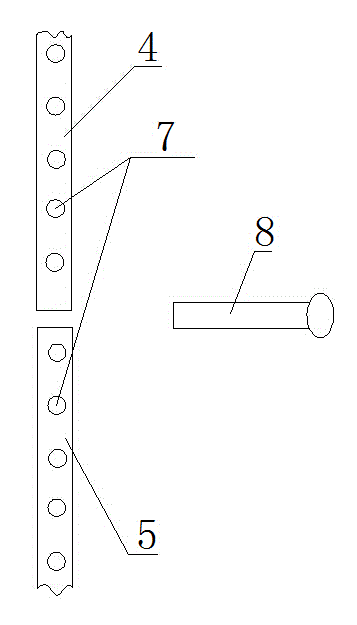

[0020] The center pole includes an upper pole 4 and a lower pole 5 . The upper rod 4 and the lower rod 5 are respectively provided with horizontally arranged holes 7, and the holes 7 on the upper and lower rods correspond to each other and a latch 8 is set in the holes to realize the connection of the upper and lower rods.

[0021] A handle is threaded onto the top of the upper pole. The handle includes an arc-shaped holding part 1 and a connecting part 2, and a connecting part is arranged under the middle part of the arc-shaped connecting part. The internal thread is processed on the connecting part, and the internal thread is processed on the upper rod, and the upper rod and the connecting part are threaded. .

[0022] The height of the top of the wire hanging rod is greater than the height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com