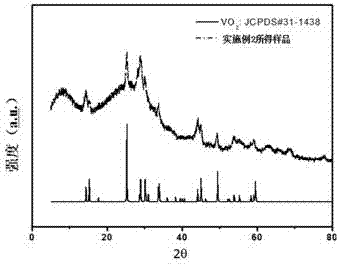

Preparation method for vanadium oxide composite electrode material used for zinc ion battery

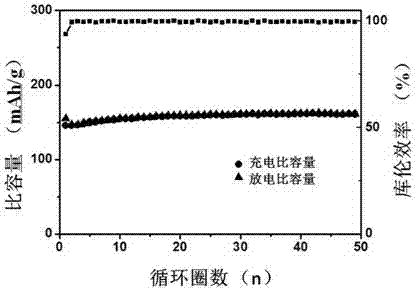

A zinc-ion battery and vanadium oxide technology, applied in the field of electrochemical materials, to achieve the effect of alleviating volume expansion, good cycle stability, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing a vanadium oxide composite electrode material for a zinc ion battery, comprising the following steps:

[0034] Step 1: Take the ammonium metavanadate solid and add it to distilled water, stir in a water bath at 50°C to obtain a light yellow clear and transparent solution with a concentration of ammonium metavanadate of about 0.03mol / L, then add 9mL of graphene oxide solution (graphene oxide Alkene solution concentration is 11mg / mL), and continue to stir, obtain the liquid that mixes homogeneously;

[0035] Step 2: Pour the mixed solution obtained in Step 1 into a small 50mL plastic beaker, put it flat, freeze it quickly in liquid nitrogen, and immediately put it into a freeze dryer for freeze-drying.

[0036] Step 3: Carry out high-temperature calcination in an argon atmosphere. The procedure is: raise the temperature to 500° C. at a rate of 1° C. / min, and calcine for 5 hours; then cool down naturally to obtain a vanadium ...

Embodiment 2

[0039] This embodiment provides a method for preparing a vanadium oxide composite electrode material for a zinc ion battery, comprising the following steps:

[0040] Step 1: Take the ammonium metavanadate solid and add it to distilled water, stir in a water bath at 50° C. to obtain a light yellow, clear and transparent solution with a concentration of ammonium metavanadate of about 0.025 mol / L, then add 3 mL of graphene oxide solution (graphene oxide Alkene solution concentration is 11mg / mL), and continue to stir, obtain the liquid that mixes homogeneously;

[0041] Step 2: Pour the mixed solution obtained in Step 1 into a small 50mL plastic beaker, put it flat, freeze it quickly in liquid nitrogen, and immediately put it into a freeze dryer for freeze-drying.

[0042] Step 3: Carry out high-temperature calcination in an argon atmosphere. The procedure is: raise the temperature to 500° C. at a rate of 1° C. / min, and calcine for 5 hours; then cool down naturally to obtain a vanad...

Embodiment 3

[0050] This embodiment provides a method for preparing a vanadium oxide composite electrode material for a zinc ion battery, comprising the following steps:

[0051] Step 1: Take the ammonium metavanadate solid and add it to distilled water, stir in a water bath at 50°C to obtain a light yellow clear and transparent solution with a concentration of ammonium metavanadate of about 0.024mol / L, then add 2.25mL of graphene oxide solution (oxidized Graphene solution concentration is 11mg / mL), and continue stirring, obtains the liquid that mixes homogeneously;

[0052] Step 2: Pour the mixed solution obtained in Step 1 into a small 50mL plastic beaker, put it flat, freeze it quickly in liquid nitrogen, and immediately put it into a freeze dryer for freeze-drying.

[0053] Step 3: Carry out high-temperature calcination in an argon atmosphere. The procedure is: raise the temperature to 250° C. at a rate of 1° C. / min, and calcine for 5 hours; then cool down naturally to obtain a vanadiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com