Embedded-sleeve-type integral molding mould for ballastless turnout slabs

A technology for integral molding and forming molds, applied in the direction of molds, mold separation devices, etc., can solve problems such as the lack of mature design of turnout plates, achieve high practical and promotional value, improve mold production efficiency, and achieve stable and reliable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

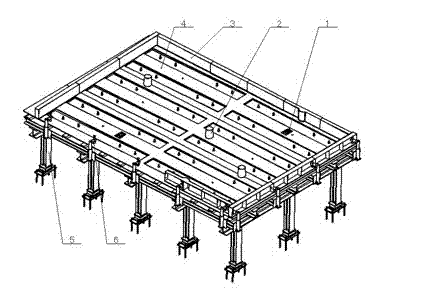

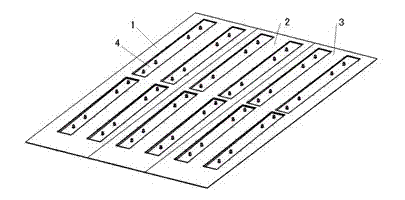

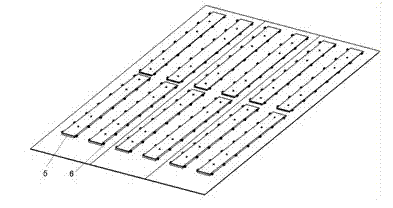

[0020] Embodiment 1: refer to Figure 1-10 . A pre-embedded casing type ballastless turnout integral molding die, which is composed of a molding die, a hoarding assembly, a pouring hole assembly, a pressing assembly and a stand system. The shroud assembly surrounds the molding die and forms a rectangular frame. The forming mold is composed of three base plates 1-3 and groove components 4, a plurality of groove components 4 are distributed on the base plate 1-3, and the perfusion hole components are respectively on the base plate 1-3. The base plate is made of ordinary steel plates with a certain thickness, and the installation grooves of the groove assembly 4 are processed by numerical control machine tools at the corresponding positions in the middle. The surface of the base plate needs to be polished. When the mold is assembled, after the three base plates are assembled seamlessly, the base plate can be tilted to form a running water slope when the cement board is manufactu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com