Solar photovoltaic heat pump dryer

A solar photovoltaic and dryer technology, applied in dryers, drying, heat pumps, etc., can solve the problems of high-power operation damage, high maintenance costs, waste of energy, etc., to reduce maintenance costs and use costs, and ensure safety. Stable operation, reducing the effect of high-power operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

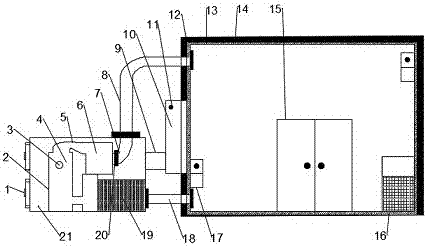

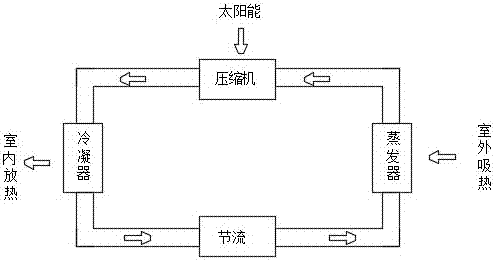

[0019] see figure 1 and figure 2 The present invention provides a solar photovoltaic heat pump dryer, which includes a box body 1 and an air-drying box 6. Since the box body 1 is made of transparent plastic, external sunlight can directly shine on the inside of the box body 1, thereby making the box body 1 The interior can heat up quickly, and the interior of the box body 1 is relatively sealed, so that the heat inside the box body 1 will not be lost, and then keep warm to ensure the heating of the equipment. There is a control box 2 on the left side of the box body 1, and the A single-chip microcomputer 19 is arranged in the box 2, a photovoltaic module 3 is arranged on the top of the box body 1, and a sliding door 11 is arranged on the front of the box body 1 at the same time, and an auxiliary heat pipe 13 and a heat pump unit 15 are arranged in the sliding door 11, and the auxiliary The heat pipe 13 is located on the left side inside the box body 1, and the heat pump unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com