Neutron and gamma ray integrated shielding filler and preparation method thereof

A comprehensive shielding and gamma ray technology, applied in the field of materials, can solve the problems affecting the comprehensive shielding performance of materials and the difference in the density of shielding components, and achieve the effect of improving the comprehensive shielding performance, improving the shielding performance and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Using boron powder (≥99.9%, 300 mesh) and tungsten powder (99.9%, 3.2μm) as raw materials, mix W and B according to the atomic ratio of 2:1, use absolute ethanol as the medium, perform high-energy ball milling, and mix After being uniform, it is dried to obtain the first mixed powder.

[0033] The homogeneously mixed first mixed powder was sintered at 1350°C under the protection of argon for 4 hours, and then synthesized by reaction to obtain W 2 B sintered body.

[0034] Will prepare W 2 The B sintered body is crushed by high-energy ball milling, and after sieving, the W material with both neutron and γ-ray shielding properties is obtained. 2 B shield filler.

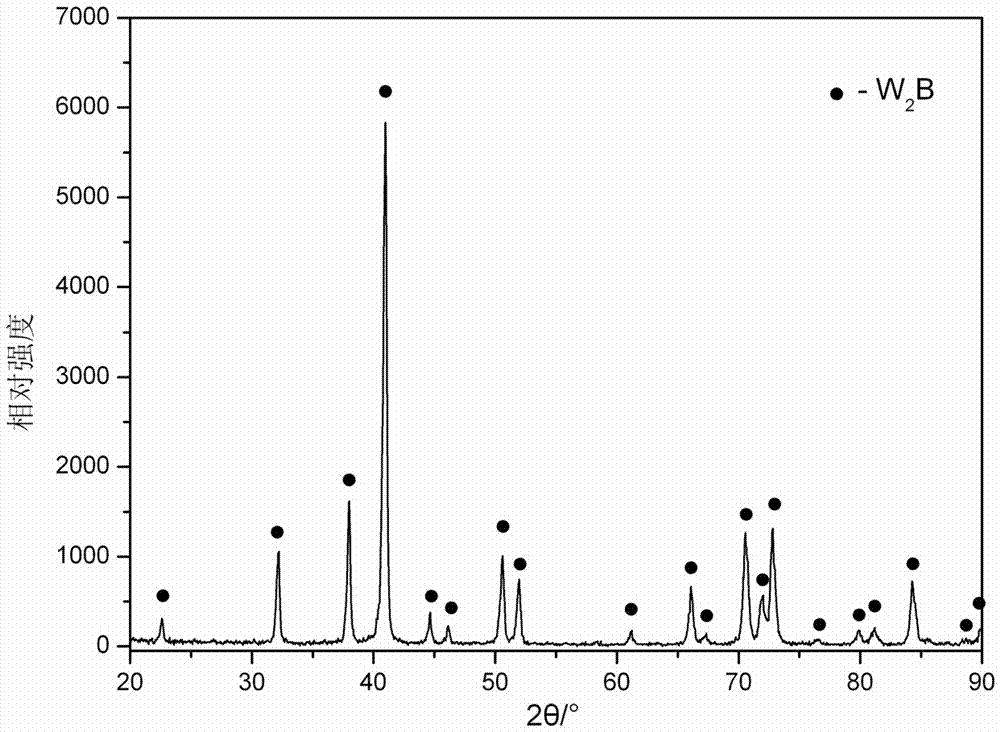

[0035] For the W prepared in this example 2 B shielding filler is measured by XRD, and its XRD analysis results are as follows figure 1 shown.

Embodiment 2

[0037] Using boron powder (≥99.9%, 300 mesh) and tungsten powder (99.9%, 2.0μm) as raw materials, W and B are mixed according to the atomic ratio of 2:1, and three-dimensional dry mixing is carried out. After mixing evenly, the first One mixed powder.

[0038] The uniformly mixed first mixed powder is subjected to cold isostatic pressing to obtain a mixed powder compact; wherein, the pressure is 180 MPa, and the holding time is 8 minutes.

[0039] The prepared mixed powder compact was sintered at a temperature of 1400 °C under the protection of argon for 2 hours, and then synthesized by reaction to obtain W 2 B sintered body.

[0040] Will prepare W 2 The sintered body of B is mechanically crushed and crushed by high-energy ball milling, and after sieving, W which has both neutron and γ-ray shielding properties is obtained. 2B shield filler.

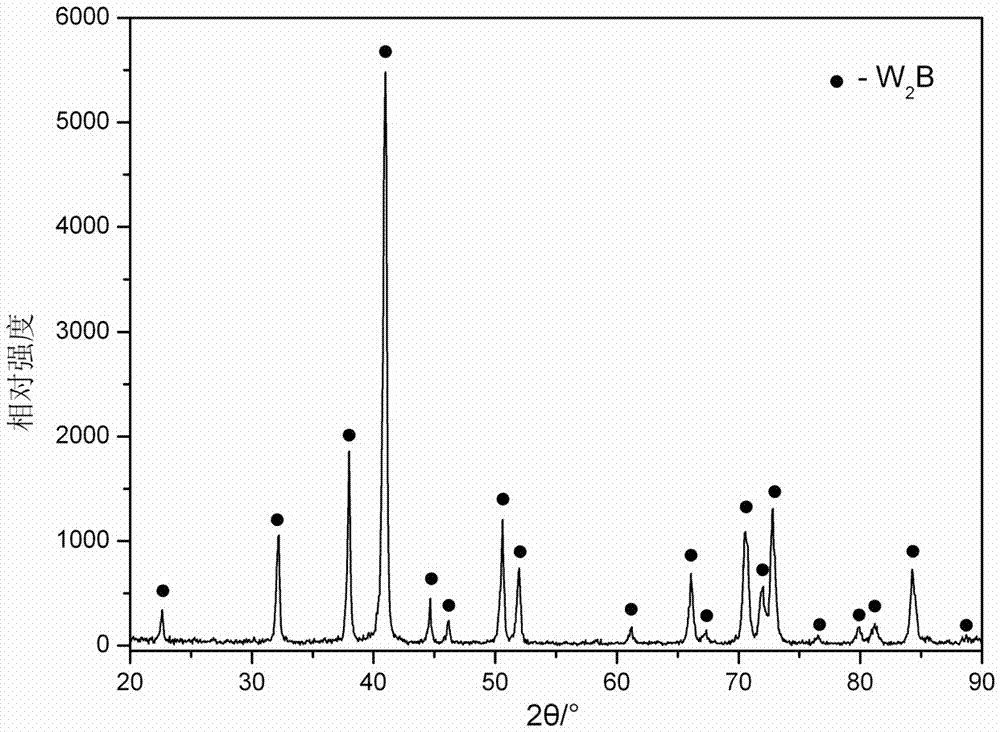

[0041] For the W prepared in this example 2 B shielding filler is measured by XRD, and its XRD analysis results are as follows f...

Embodiment 3

[0043] Boron powder (≥99.9%, 300 mesh) and tungsten powder (99.9%, 300 mesh) are used as raw materials, and the atomic ratio of W and B is 2:1 for batching, and acetone is used as the medium for high-energy ball milling. After mixing evenly, Dry to obtain the first mixed powder.

[0044] The uniformly mixed first mixed powder is subjected to cold isostatic pressing to obtain a mixed powder compact; wherein, the pressure is 100 MPa, and the holding time is 10 minutes.

[0045] The prepared mixed powder compact was sintered at a temperature of 1300 °C for 4 hours in a high-temperature vacuum, and the W 2 B sintered body.

[0046] Will prepare W 2 The sintered body of B is mechanically crushed and crushed by high-energy ball milling, and after sieving, W which has both neutron and γ-ray shielding properties is obtained. 2 B shield filler.

[0047] For the W prepared in this example 2 B shielding filler is measured by XRD, and its XRD analysis results are as follows image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com