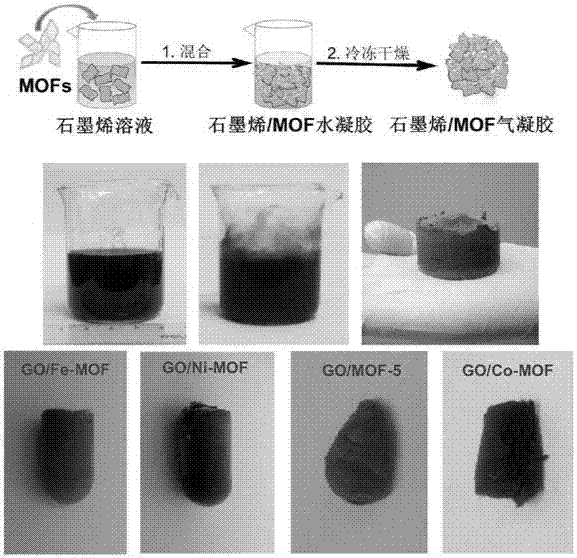

Method for preparing graphene/MOF (metal-organic framework) porous composite material aquagel and graphene/MOF porous composite material aerogel

A porous composite material and graphene technology, which is applied in the field of preparation of graphene/metal organic framework compound porous composite hydrogel and aerogel, can solve the problem of long time-consuming stirring and mixing, weak interaction force and uncontrollable product shape And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0041] 1. Sample preparation

[0042] (1) The preparation of embodiment 1 sample is carried out as follows:

[0043] Configure a 250mL reaction bottle in an ice bath, add 96mL of concentrated sulfuric acid, add 2g of graphite powder and 1g of sodium nitrate (>99%) solid mixture under magnetic stirring, then slowly add 6g of potassium permanganate (>99.6%), Control the reaction temperature not to exceed 10°C, take it out after reacting in an ice bath for 2h, and stir in a water bath at 35°C for 18h. As the reaction progressed, the reactant finally turned into a brown slurry, and then slowly added a 5% sulfuric acid solution to it for dilution. After adding 240mL of sulfuric acid solution, 5mL of hydrogen peroxide with a mass fraction of 30% was added thereto, and the solution turned bright yellow as the bubbles burst out. After continuous stirring for 2 hours, filter, and then wash with 10% hydrochloric acid solution and deionized water several times until the solution is neu...

Embodiment 6

[0059] (5) FTIR spectral analysis

Embodiment 1

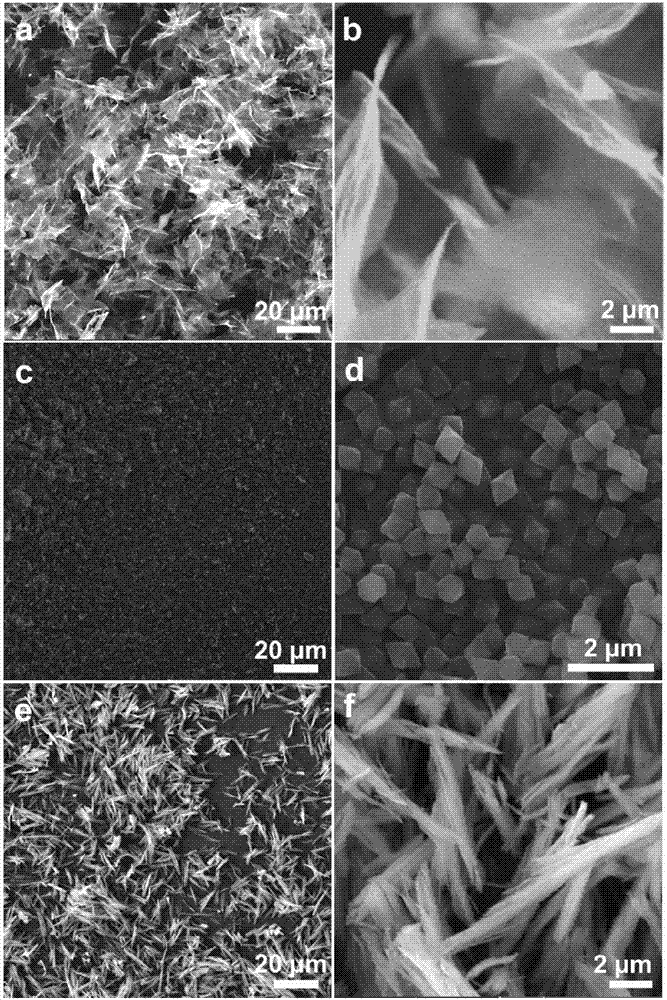

[0062] The surface morphology of the pure GO airgel obtained in Example 1 is as follows: figure 2 (a,b). figure 2 (a) shows the overall morphology of the airgel. It can be seen that the three-dimensional framework is made of a large number of overlapping GO sheets, and countless micron-scale channels are constructed. figure 2 (b) is figure 2 (a) Partial enlarged view. From (b), it can be clearly seen that the GO sheets are transparent, indicating that the GO sheets have not agglomerated, which further proves that this self-supporting porous structure is constructed by a large number of single-layer GO sheets. figure 2 (c, d) are SEM images of the Fe-MOF crystal powder obtained in Example 2. It can be seen from figure (d) that the obtained Fe-MOF crystal is a polygonal spindle with a lateral dimension of several hundred nanometers.

[0063] Figure 4 with Figure 5 (a, b) are SEM images of the GO / Fe-MOF composite airgel obtained in Examples 3-6, respectively. It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com