Method for improving structure properties of high-silicon aluminum alloy

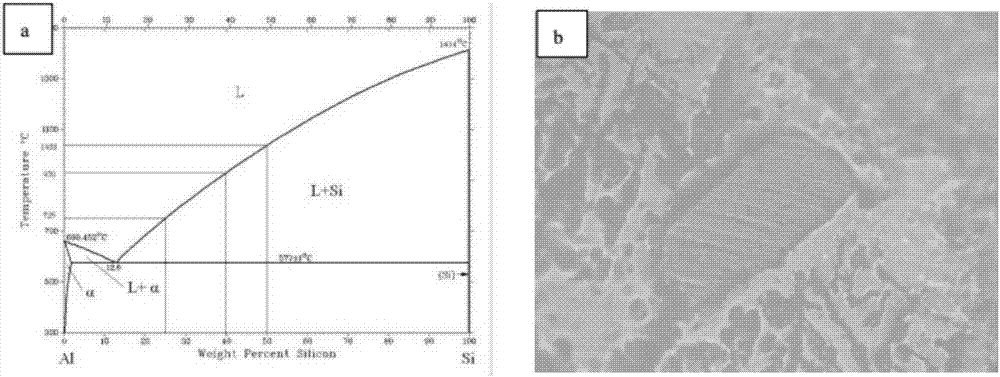

A high-silicon aluminum alloy, microstructure and performance technology, applied in the field of alloy manufacturing, can solve problems such as coarseness, increased brittleness, and failure to meet the performance requirements of aluminum-silicon alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

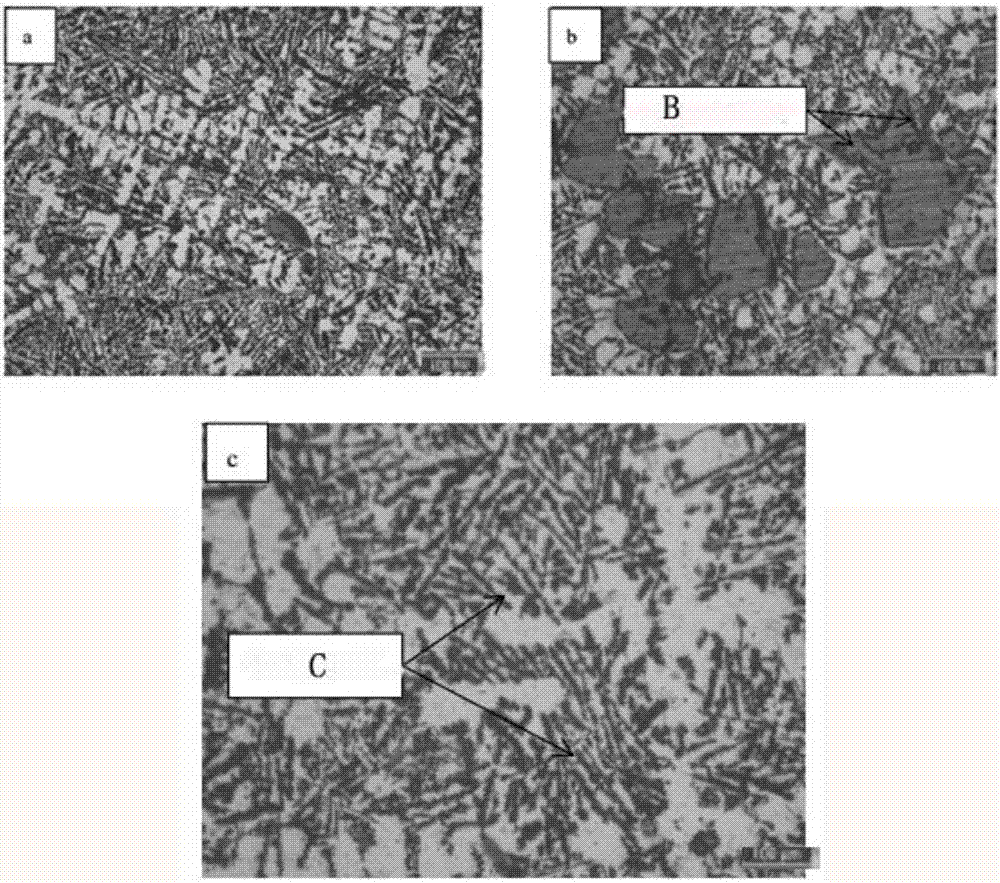

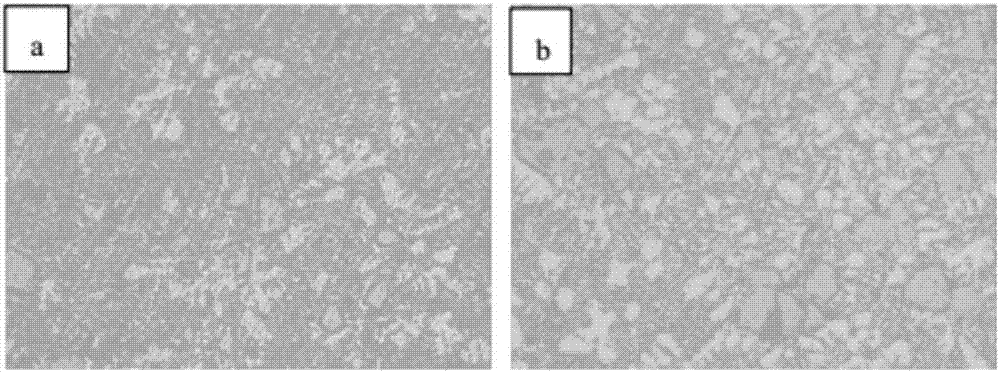

Embodiment 1

[0058] A method for improving the structure and properties of high-silicon aluminum alloys, comprising the following steps: taking high-silicon aluminum alloys, putting them into a graphite crucible and placing them in a well-type furnace, setting the heating rate at 10°C / min and setting the temperature at 760°C, then raising the temperature, After reaching the set temperature, keep it warm for 40 minutes, then take out the graphite crucible, put it into a low-frequency magnetic field coil, and carry out electromagnetic and mechanical coupling stirring for 15 minutes under the condition of heat preservation. After the stirring is completed, cast it and cool it to room temperature. Wherein, the high-silicon aluminum alloy is an alloy whose mass fraction of silicon is 20%. The ceramic stirring rod is preheated at 600° C. for 15 minutes, the magnetic field strength of the low-frequency magnetic field is 12000 AT, and the frequency of mechanical stirring is 2 Hz.

Embodiment 2

[0060] A method for improving the structure and properties of high-silicon aluminum alloys, comprising the following steps: taking high-silicon aluminum alloys, putting them into a graphite crucible and placing them in a well-type furnace, setting the heating rate at 15°C / min and setting the temperature at 800°C, and then raising the temperature, After reaching the set temperature, keep it warm for 25 minutes, then take out the graphite crucible, put it into a low-frequency magnetic field coil, and carry out electromagnetic and mechanical coupling stirring for 5 minutes under the condition of heat preservation. After the stirring is completed, cast it and cool it to room temperature. Among them, the ceramic stirring rod is preheated at 700° C. for 15 minutes, the magnetic field strength of the low-frequency magnetic field is 15000 AT, and the frequency of mechanical stirring is 3 Hz.

Embodiment 3

[0062] A method for improving the structure and properties of high-silicon aluminum alloys, comprising the following steps: taking high-silicon aluminum alloys, putting them into a graphite crucible and placing them in a well-type furnace, setting the heating rate at 12°C / min and setting the temperature at 780°C and then raising the temperature, After reaching the set temperature, keep it warm for 30 minutes, then take out the graphite crucible, put it into a low-frequency magnetic field coil, and carry out electromagnetic and mechanical coupling stirring for 15 minutes under the condition of heat preservation. After the stirring is completed, cast it and cool it to room temperature. Among them, the high-silicon aluminum alloy is an alloy with a mass fraction of silicon of 20%, the ceramic stirring rod is preheated at 650°C for 15 minutes, the magnetic field strength of the low-frequency magnetic field is 13000AT, and the frequency of mechanical stirring is 2.5Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com