A preparation method of degradable medical polymer three-dimensional material for improving osteoblast adhesion and osteogenic performance

A polymer material and osteoblast technology, applied in the field of biodegradable medical polymer nanocomposite materials and bionic modification, to achieve good osteogenic performance, reduce impact, and the effect of simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

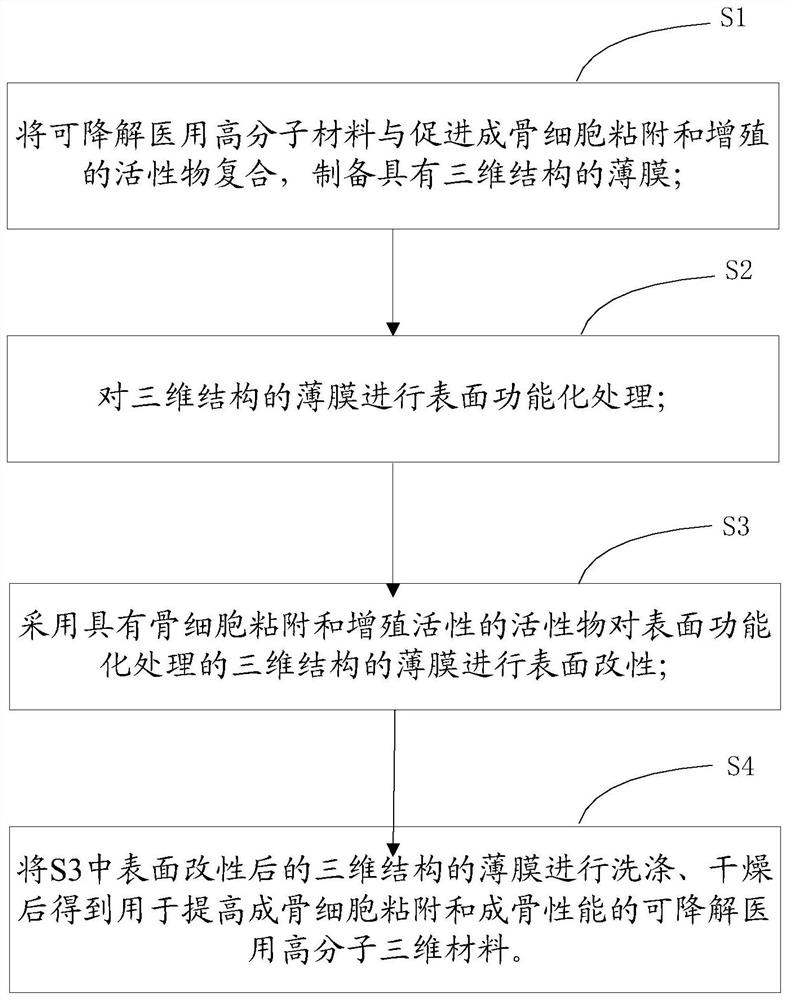

[0025] ginseng figure 1 As shown, the preparation method of a degradable medical polymer three-dimensional material for improving osteoblast adhesion and osteogenic performance in an embodiment of the present invention includes the following steps:

[0026] S1. Combining degradable medical polymer materials with active substances that promote the adhesion and proliferation of osteoblasts to prepare a film with a three-dimensional structure. Specifically, the electrospinning method is used to compound degradable medical polymer materials and active substances that promote the adhesion and proliferation of osteoblasts to prepare a film with a three-dimensional structure. In the film with a three-dimensional structure, the content of the active substances promoting the adhesion and proliferation of osteoblasts is 0.05wt% to 20wt%, and the added active substances promoting the adhesion and proliferation of osteoblasts are evenly distributed without damaging Structural and mechani...

Embodiment 1

[0033] Weigh 1g PLGA, 10% chitosan, put into trifluoroethanol solution, stir magnetically, dissolve evenly. Under the parameters of positive pressure 18.5kv, negative pressure 2.8kv, humidity 35%, and temperature 19°C, a film with a three-dimensional structure was prepared by electrospinning, and the obtained film was dried in a vacuum oven for 48 hours to remove the solvent; The obtained thin film material with a three-dimensional structure was subjected to surface functionalization treatment with dopamine, in a Tris-HCl solution with a pH value of 8.5 and a concentration of 0.3 wt% dopamine, reacted for 24 h, and washed three times with deionized water. After pretreatment in 2% glutaraldehyde for 1 h, they were washed three times with deionized water. In a 5 wt% collagen solution, react for 24 h, control the temperature at 37 °C, wash with deionized water three times, and dry in a vacuum oven for 48 h to obtain the product.

[0034] The prepared electrospun membrane materia...

Embodiment 2

[0036] Weigh 1 g of PLGA in trifluoroethanol solution, stir magnetically, dissolve evenly, add 250 μL of collagen and mix well with magnetic stirring. A film with a three-dimensional structure was prepared by electrospinning under the parameters of positive pressure 16.23 kv, negative pressure 2.33 kv, humidity 32%, and temperature 19°C. The obtained film was dried in a vacuum oven for 48 h to remove the solvent; The obtained thin film material with a three-dimensional structure was subjected to surface functionalization treatment in a Tris-HCl solution with a pH value of 8.5 and a concentration of 0.1 wt% dopamine, reacted for 24 h, and washed three times with deionized water. In 6 wt% BMP2 solution, react for 36 h, control the temperature at 37 °C, wash with deionized water three times, and dry in a vacuum oven for 48 h to obtain the product.

[0037] The prepared electrospun membrane material has a three-dimensional structure, and the pre-osteoblast MC3T3-E1 culture results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com