Piperazine phosphate controlled-release agent and preparation method thereof

A technology of piperazine phosphate and slow-release agent, which is applied in the directions of pill delivery, pharmaceutical formulation, coating, etc., can solve the problems of too fast release of piperazine phosphate tablets and poor repellent effect, etc., and achieves improved repellent effect and extended time. , the effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

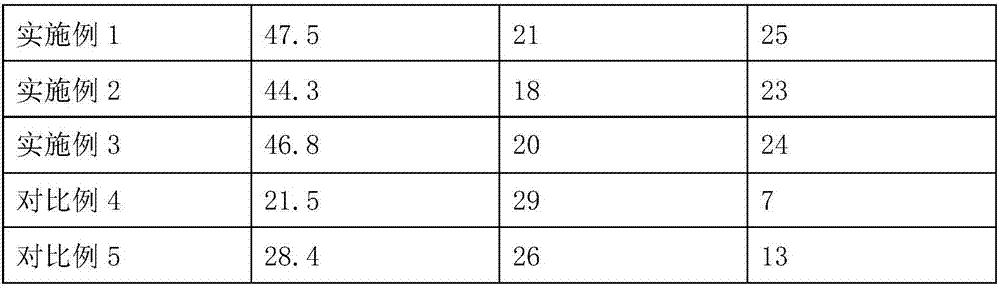

Examples

preparation example Construction

[0023] The invention provides a preparation method of piperazine phosphate slow-release agent, comprising the following steps:

[0024] a. Mix piperazine phosphate powder and oligosaccharide evenly in a weight ratio of 3-5:1-2, add edible gelatin accounting for 3-5wt% of the raw material weight, add water to a water content of 5-8%, and stir evenly to obtain material A ;

[0025] b. Compress material A into tablets to make uniform tablets;

[0026] c. Weigh raw materials by weight of 10-20 parts of polycation electrolyte, 10-20 parts of polyanion electrolyte, 30-35 parts of small molecule crosslinking agent, and 5-10 parts of oligosaccharide, mix them uniformly and add water to prepare 0.01- 0.02g / ml solution;

[0027] d. Spray the solution obtained in step c onto the surface of the tablet described in step b, and dry to form a coating film to prepare the piperazine phosphate sustained-release preparation.

[0028] Wherein, in the preparation method of the above-mentioned p...

Embodiment 1

[0042] Embodiment 1 prepares piperazine phosphate slow-release agent with the inventive method

[0043] Prepare piperazine phosphate slow-release agent, comprising the following steps:

[0044] a. Mix piperazine phosphate powder and oligosaccharide evenly in a weight ratio of 3:1, add edible gelatin accounting for 3wt% of the raw material weight, add water to a water content of 5%, stir evenly, and stir at 300r / s for 1h to obtain the material A;

[0045] b. Tablet the material A at 50°C and a pressure of 0.4Mpa to make a uniform tablet;

[0046] c, 10 parts by weight of mannan, 10 parts of xanthan gum, 30 parts of sodium tripolyphosphate, and 5 parts of oligosaccharides are weighed to prepare a 0.01 g / ml solution by adding water after mixing;

[0047] d. Spray the solution obtained in step c onto the surface of the tablet described in step b, and dry at 70° C. for 45 minutes to form a coating film to prepare the piperazine phosphate sustained-release preparation.

Embodiment 2

[0048] Embodiment 2 prepares piperazine phosphate slow-release agent with the inventive method

[0049] Prepare piperazine phosphate slow-release agent, comprising the following steps:

[0050] a. Mix piperazine phosphate powder and oligosaccharide evenly in a weight ratio of 5:1, add edible gelatin accounting for 4wt% of the raw material weight, add water to a water content of 7%, stir evenly, and stir at 350r / s for 1.5h during stirring to obtain Material A;

[0051] b. Tablet the material A at 60°C and a pressure of 0.45Mpa to make a uniform tablet;

[0052] c, 15 parts by weight of mannan, 15 parts of xanthan gum, 30 parts of sodium tripolyphosphate, 10 parts of oligosaccharides are weighed raw materials, mixed evenly, add water to prepare a 0.02g / ml solution;

[0053] d. Spray the solution obtained in step c onto the surface of the tablet described in step b, and dry at 80° C. for 50 minutes to form a coating film to prepare the piperazine phosphate sustained-release prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com