Micro-scale initiating explosive device ignition temperature field measuring device and temperature measurement method thereof

A technology of combustion temperature and measurement method, applied in the field of temperature measurement, can solve the problems of increasing the measurement error of the sensor, unable to solve the temperature of the object, etc., and achieves the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

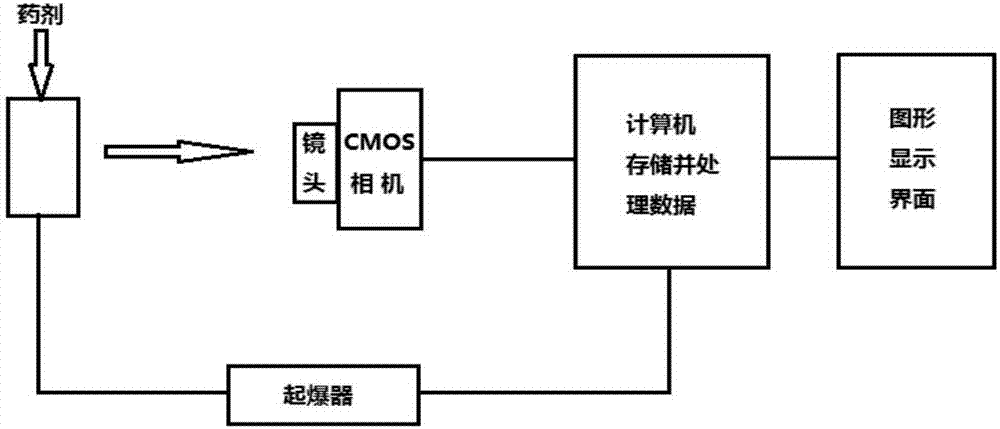

[0027] A high-temperature and high-speed measurement device for micro-scale pyrotechnics, including:

[0028] High-speed camera 6, this high-speed camera 6 is coaxially arranged with imaging lens 5, and described imaging lens 5 is arranged on one side of high-speed camera 6, and computer 9 is set at the other side of high-speed camera; Imaging lens is used for microscale fire The light emitted by the burning product is imaged on the negative film of the camera sensor, and the computer is used to process the collected images. The computer is connected with a trigger for triggering the burning of the pyrotechnic product.

[0029] The high-speed camera is a camera of the phantom brand, which has multiple frame numbers and resolutions to choose from. According to the actual situation of pyrotechnics burning and the requirements of measurement, the frame number of the selected camera is 58000 frames, and the resolution is 64× With 64 pixels and a pixel size of 22 μm, the target sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com