Method for scraping crude oil channel wall wax layer

A channel wall and wax layer technology, applied in earthwork drilling, cleaning equipment, wellbore/well components, etc., can solve problems such as oil pressure rise, oil pipe blockage, oil well wax deposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

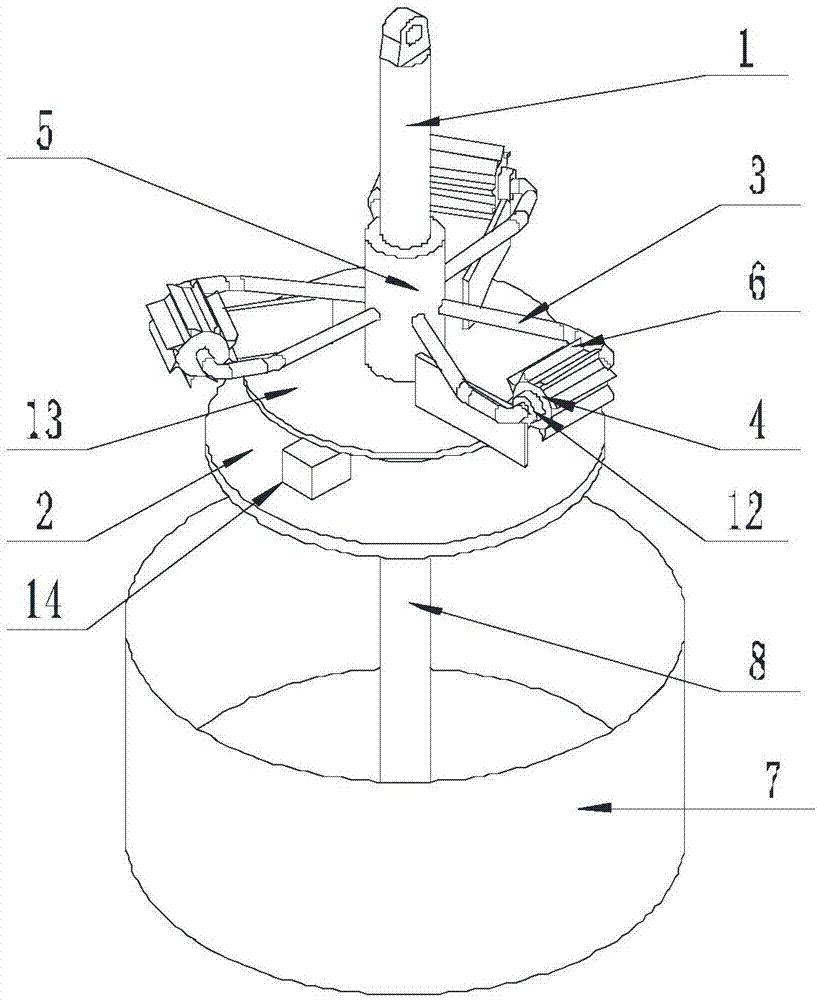

[0036] Such as Figure 1-Figure 6 Shown, the method that the present invention scrapes off crude oil passage wall wax layer, comprises the steps:

[0037] Step A preparation: fix the winch 9 next to the oil well, fix the fixed wheel 11 above the oil well inlet, connect one end of the wire rope 10 to the winch 9, and connect the other end of the wire rope 10 to one end of the connecting shaft 1 after bypassing the fixed wheel 11;

[0038] Step B wax scraping: start the winch 9, lengthen the wire rope 10, so that the wax removal assembly falls along the diameter of the oil well;

[0039] Start the driving device I and the driving device II at the same time, the driving device II makes the scraper 6 rotate around the axis of the support cylinder 4 to scrape off the wax layer on the well wall; the driving device I makes the scraper assembly rotate around the connecting shaft 1 to Scrape off the wax layer around the well wall;

[0040] Step C Exit: Start the winch 9, shorten the ...

Embodiment 2

[0045] The present invention is based on embodiment 1, and the present invention is further described.

[0046] Such as Figure 1-Figure 6As shown, in the method for scraping the wax layer on the wall of the crude oil channel in the present invention, the support shaft 3 is bent into a C shape, and its ends are connected to the side wall of the installation cylinder 5, and the support cylinder 4 is located on the support shaft 3 away from the installation cylinder 5 on the shaft.

[0047] Further, the cross-section of the scraper 6 is triangular, its base is connected to the support cylinder 4, its waistlines are all arc-shaped, and the inner concave surface of one waistline faces the center of the triangle, and the inner concave surface of the other waistline The concave face faces away from the center of the triangle. The cross-section of the scraper 6 is set as a triangle, and the two waistlines are arcs, which is beneficial for the scraper 6 to scrape off the wax layer o...

Embodiment 3

[0052] The present invention further explains the suspension device on the basis of Embodiment 2.

[0053] Such as Figure 1-Figure 6 As shown, the method for scraping the wax layer on the wall of the crude oil channel in the present invention, the suspension device includes a fixed wheel 11, a winch 9 and a steel wire rope 10, one end of the steel wire rope 10 is connected with the winch 9, and the other end of the steel rope walks around the fixed wheel After 11, it is connected with the connecting shaft 1, and the winch 9 makes the connecting shaft 1 move along the axis perpendicular to the horizontal plane by retracting and unwinding the wire rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com