Alcohol-containing sewage pretreatment process

A sewage pretreatment and process technology, applied in the direction of water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of high oil content alcohol sewage sewage oil recovery, methanol sewage entering the system blockage, It does not settle the problems of suspended matter and emulsified oil, and achieves the effect of reducing sediment accumulation, preventing blockage and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In order to overcome the existing problems of high cost of gas production and blockage, corrosion and scaling of the methanol recovery device used, the present invention provides an alcohol-containing sewage pretreatment process, which solves the problem of high-silt methanol sewage entering the system blockage , High oil content, alcohol-containing sewage and dirty oil recovery problems and difficult to deal with unsettled suspended solids and emulsified oil in alcohol-containing sewage, not only reduce gas production costs, but also control oil content and suspended solids content, and ensure the smooth operation of subsequent methanol regeneration units.

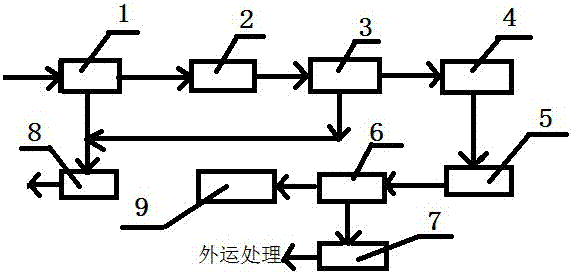

[0029] A pretreatment process for alcohol-containing sewage, the specific steps are:

[0030] Step 1: The alcohol-containing sewage hauled from the gas gathering station is transported to the water treatment station and unloaded to the grit chamber 1 for preliminary separation of oil and sediment.

[0031] The alco...

Embodiment 2

[0038] Based on the above embodiments, in this embodiment, in the first step, the waste oil after the preliminary oil and sediment separation is directly stored in the buried oil transfer tank 8 .

[0039] In the second step, after the secondary oil-water separation is completed through the primary booster pump 2 and the storage tank 3, a certain amount of water is stored in the storage tank 3 at the same time, and the water quality is adjusted so that the oil content in the separated sewage is ≤ 1000mg / L.

[0040] In the third step, the outlet water of the storage tank 3 is lifted by the secondary booster pump 4 and enters the heat exchanger 5 to raise the water temperature to 20°.

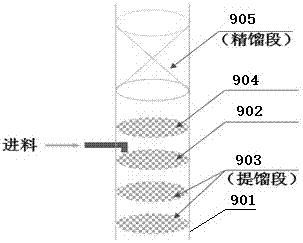

[0041] In said step 4, for the removal of non-sinkable suspended solids and emulsified oil, a certain amount of oil is added to the alcohol-containing sewage to be treated, and then the medicament is added after emulsification, and the alum flowers generated by the medicament are added to absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com