Preparation method and application of heteroatom-doped metal carbon-containing material

A heteroatom and metal technology, applied in the field of preparation of metal carbonaceous materials, can solve the problems of limited degree of graphitization, limited catalytic ability, large specific surface area of materials, etc., and achieves the effect of strong stability and improved electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Part of the specific embodiments of the present invention provides a method for preparing a heteroatom-doped metal carbonaceous material, the preparation method comprising the following steps:

[0056] (1) Dissolving metal ions, imidazole ligand compounds and water-soluble polymers in solvent A;

[0057] (2) adding the graphene oxide solution to the solution in step (1) after a period of time;

[0058] (3) mixing and stirring the solutions of steps (1) and (2), separating the solid and liquid, and calcining the obtained precipitate under the protection of an inert gas to obtain a nitrogen-doped metal carbonaceous material;

[0059] (4) Put the nitrogen-doped metal carbonaceous material obtained in step (3) into the high-temperature zone of the double-temperature-controlled vacuum tube furnace, and place the material containing heteroatoms in the low-temperature zone, and heat it under high temperature with inert protective gas and low pressure. calcining to obtain a he...

Embodiment 1

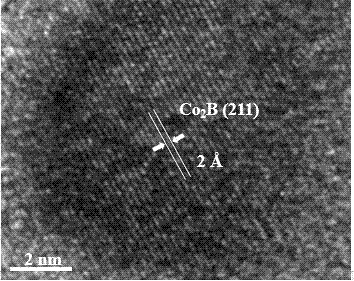

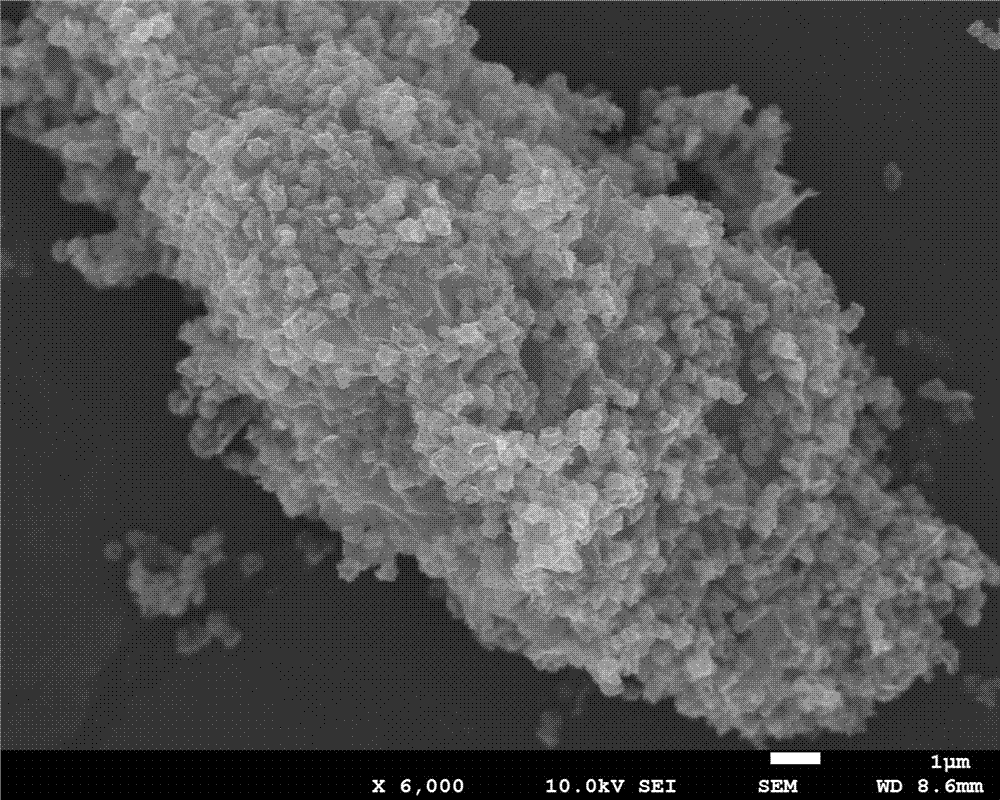

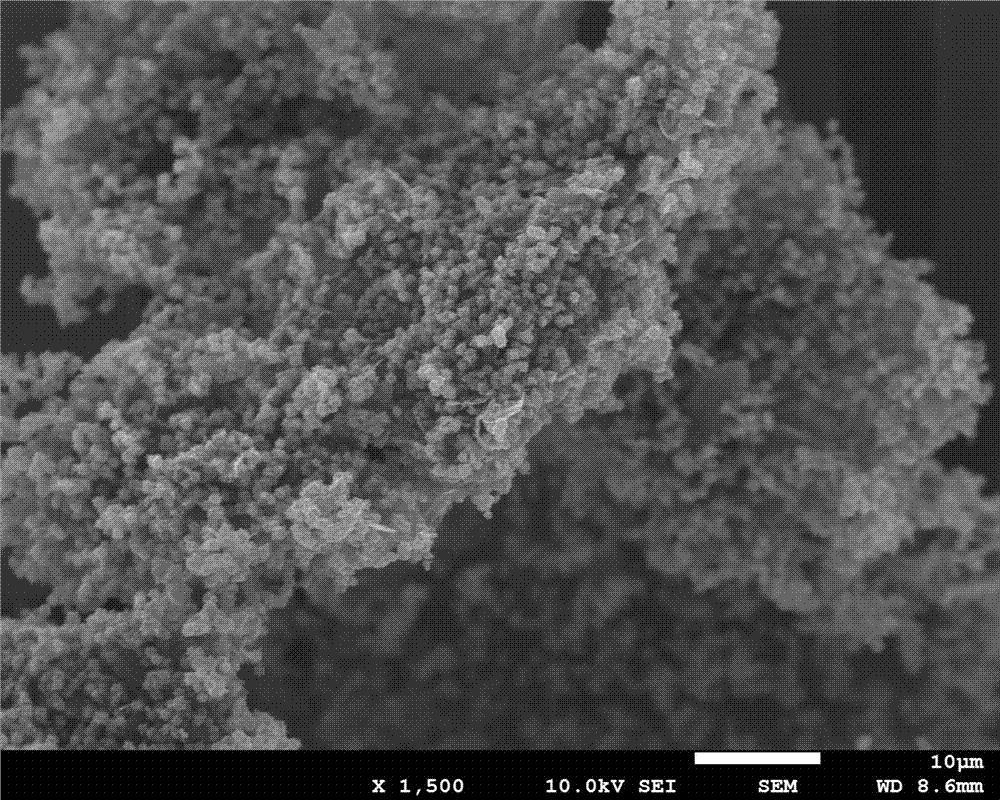

[0061] A method for preparing a three-dimensional cobalt-carbon material doped with boron and nitrogen atoms, the preparation method comprising the following steps:

[0062] (1) Dissolve 0.5 M cobalt sulfate, 0.5 M 2-methylimidazole and 0.5 g polyacrylamide in 50 mL acetonitrile solvent, and stir at 200 rpm;

[0063] (2) After 30 s, add 0.1 g / L, 1 mL graphene oxide solution to the solution in step (1);

[0064] (3) Mix the solutions obtained in steps (1) and (2) and stir at a speed of 200 rpm for 1 h, then centrifuge at a speed of 10,000 rpm for 1 min to separate the solid from the liquid. Drying at 80 ℃ for 12 h, followed by calcination under nitrogen protection for 2 h, the calcination temperature was 750 ℃, and the calcination heating rate was 5 ℃ / min to obtain the nitrogen-doped cobalt carbon material N-Co / C-1;

[0065] (4) Put 1 g of the N-Co / C-1 material obtained in step (3) into the high-temperature zone of a double-temperature-controlled vacuum tube furnace for 10 min...

Embodiment 2

[0068] A method for preparing a three-dimensional cobalt-carbon material doped with fluorine, boron and nitrogen atoms, the preparation method comprising the following steps:

[0069] (1) Dissolve 0.5 M cobalt oxide, 1 M 4-nitroimidazole and 4 g polyvinylpyrrolidone in 50 mL N,N-dimethylacetamide solvent;

[0070] (2) After 60 s, add 1 g / L, 4 mL graphene oxide solution to the solution in step (1);

[0071] (3) Mix the solutions of steps (1) and (2) and stir at 200 rpm for 1.5 h, then centrifuge at 11,000 rpm for 2 min to separate the solid from the liquid. Drying at ℃ for 14 h, calcining for 3 h under the protection of nitrogen, the calcination temperature is 700 ℃, and the calcination heating rate is 6 ℃ / min, and the nitrogen-doped three-dimensional cobalt carbon material N-Co / C-2 is obtained;

[0072] (4) Put the N-Fe / C-4 material obtained in step (3) into the high-temperature zone of a double-temperature-controlled vacuum tube furnace for 20 min. The temperature in the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com