Self-riveting motor rotor iron core

A motor rotor, self-riveting technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, electrical components, etc., can solve the problem of increasing the maximum torque of squirrel cage motors, so as to improve operating efficiency and increase The effect of maximizing torque and reducing the size of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

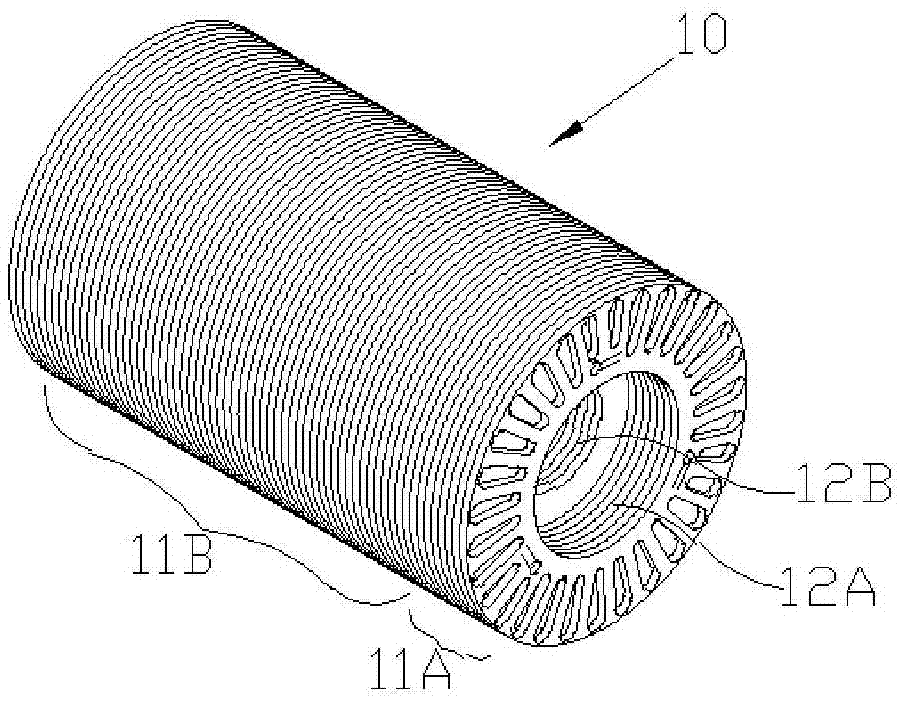

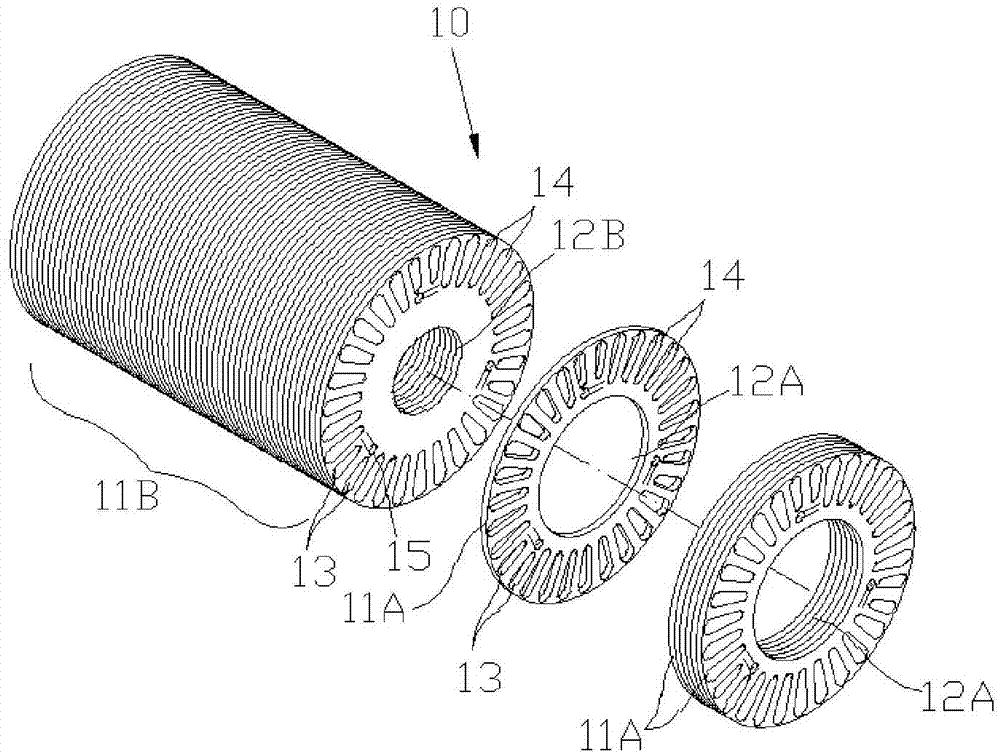

[0042] The present invention mainly provides a self-riveting motor rotor core that can effectively increase the motor torque, such as figure 1 and figure 2 As shown, the self-riveting motor rotor core of the present invention has a core body 10 composed of a plurality of silicon steel sheets (such as the silicon steel sheet 11A and the silicon steel sheet 11B shown in the figure) stacked and combined. Its center is provided with a shaft hole 12A, 12B, and each of the silicon steel sheets 11A, 11B is provided with a plurality of slots arranged around the shaft holes 12A, 12B to which it belongs (slot holes 13 and slots as shown in the figure) Holes 14), each of the silicon steel sheets 11A, 11B has a plurality of self-riveting points 15 evenly distributed in the area between the shaft holes 12A, 12B and the slot holes 13, 14 to which they belong.

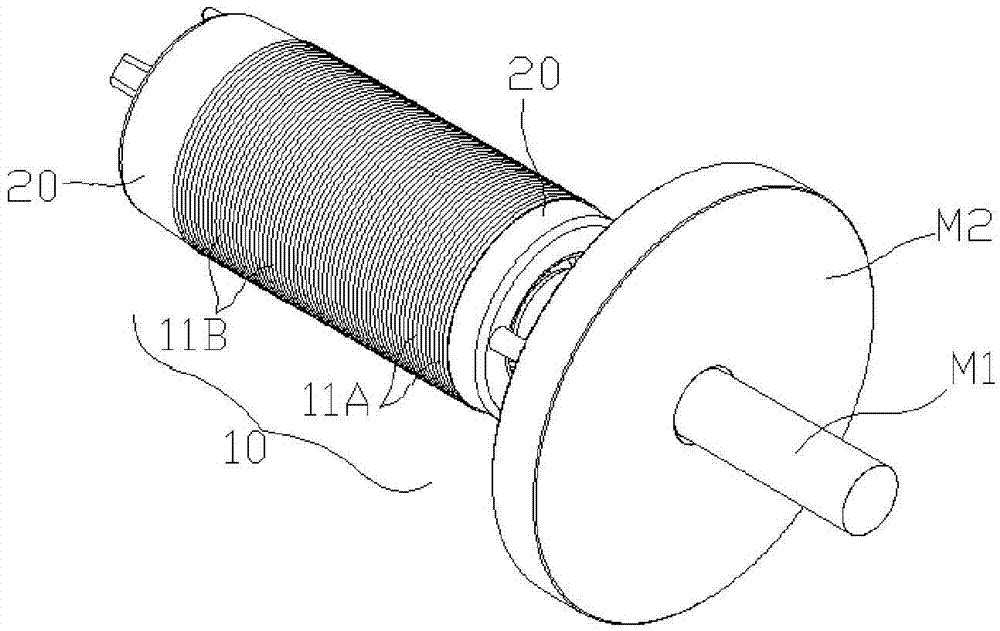

[0043] Also, the two ends of the core body 10 are respectively fixed with a metal end ring 20 connected to the inside of the slot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com