Ultrathin sound absorption structure capable of sound absorption in wide low-frequency range

A sound-absorbing, ultra-thin technology, applied in the field of acoustics, can solve problems such as limiting engineering applications, single fixed frequency, limiting practical applications, etc., and achieve the effect of widening the bandwidth of the sound-absorbing frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

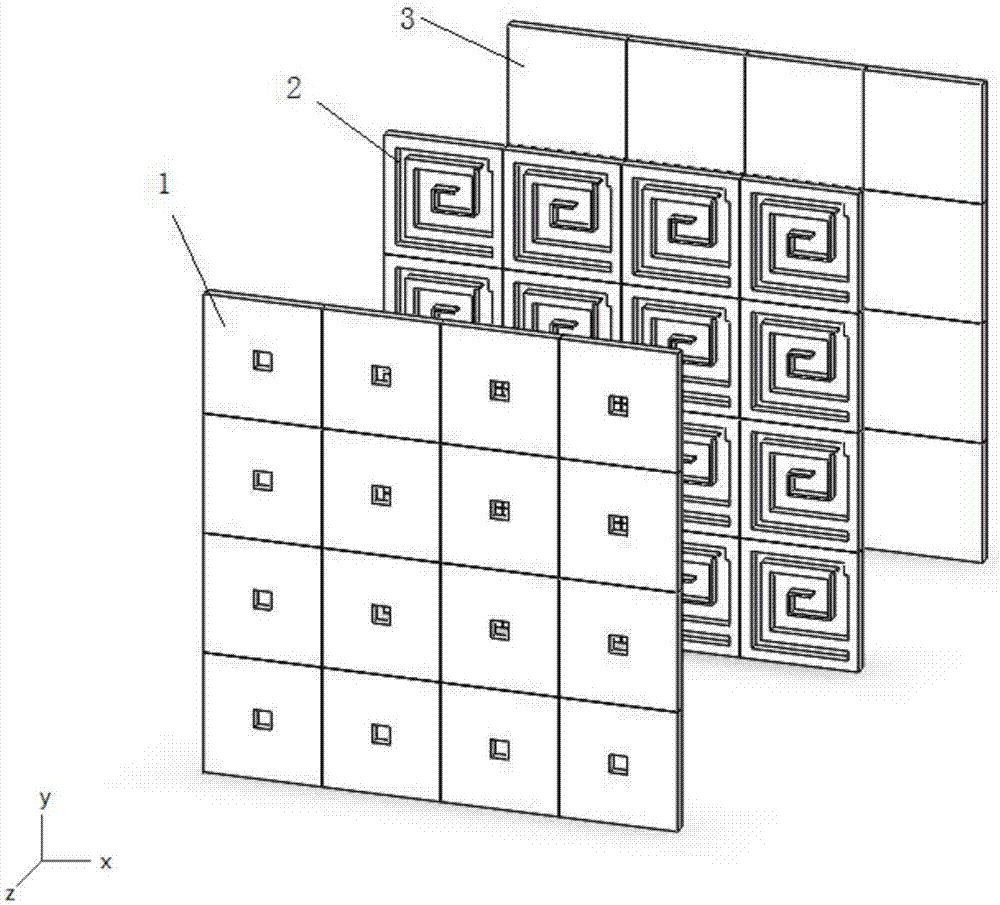

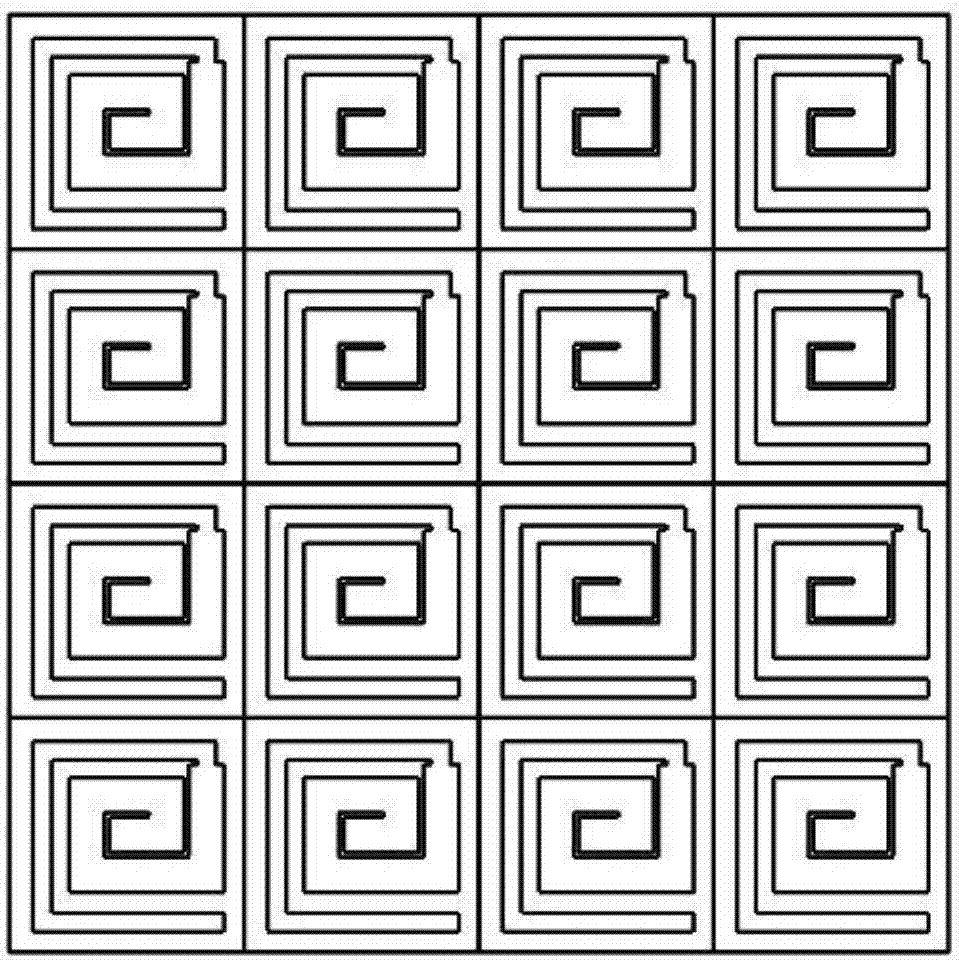

[0071] Example 1: The middle layer is processed with coiled solenoids of different sizes for serial distribution

[0072] The materials used in the front panel 1, the middle layer 2 and the rigid back panel 3 are all PLA. PLA is a commonly used 3D printing material, and its tensile strength and flexural modulus are both greater than 60Mpa, meeting the rigidity requirements of ultra-thin sound-absorbing structures;

[0073] See attached Figure 5-6 , The side length D of the front panel 1, the middle layer 2 and the rigid back panel 3 are all 100mm, and the total thickness h is 23.3mm;

[0074] Wherein, the thickness of the front panel 1 is 1mm; the geometric center of the front panel 1 is provided with a square through hole, the side length of the square through hole is 21.3mm, and the geometric center of the square through hole coincides with the geometric center of the front panel 1 ;

[0075] The thickness of the middle layer 2 is 21.3mm; the middle layer 2 is processed with a squa...

example 2

[0079] Example 2: The middle layer is processed with coiled solenoids of different sizes for serial distribution

[0080] The materials used in the front panel 1, the middle layer 2 and the rigid back panel 3 are all metal aluminum. The elastic modulus of aluminum is 69Gpa, which meets the requirements of sound-absorbing structures for rigid walls;

[0081] See attached Figure 8-9 , The side length D of the front panel 1, the middle layer 2 and the rigid back panel 3 are all 108.4mm, and the total thickness h is 6.5mm;

[0082] Wherein, the thickness of the front panel 1 is 0.1mm; the front panel 1 is processed with a 53mm*6mm rectangular through hole at a position 0.2mm away from two adjacent right-angle sides;

[0083] The thickness of the middle layer 2 is 6mm; the middle layer 2 is processed with a rectangular through hole with the same position and size as the rectangular through hole of the front panel 1; the long side of the rectangular through hole is the starting point (that...

example 3

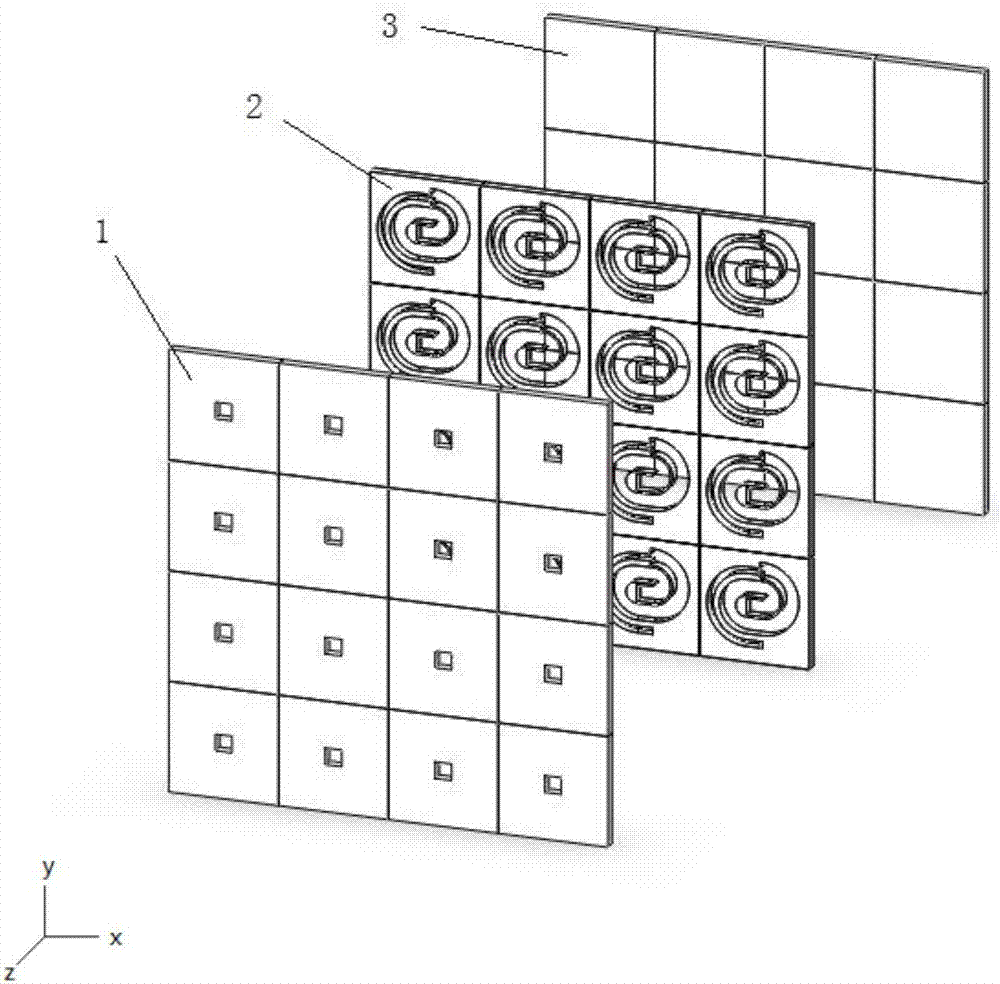

[0087] Example 3: The middle layer is processed with coiled solenoids of different sizes for mixed-connection distribution

[0088] The materials used in the front panel 1, the middle layer 2 and the rigid back panel 3 are all metal aluminum. The elastic modulus of aluminum is 69Gpa, which meets the requirements of sound-absorbing structures for rigid walls;

[0089] See attached Figure 11-12 , The side length D of the front panel 1, the middle layer 2 and the rigid back panel 3 are all 100mm, and the total thickness h is 30.4mm;

[0090] Wherein, the thickness of the front panel 1 is 0.2mm; the front panel 1 is processed with two diagonal square through-holes, the two square through-holes are respectively closest to two adjacent right-angled sides at a distance of 2mm. The side lengths of each square through hole are 30mm and 26mm respectively;

[0091] The thickness of the middle layer 2 is 6mm; the middle layer 2 is processed with two square through holes with the same position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com