System for removing hydrogen sulfide from drilling fluid

A technology for removing system and drilling fluid, which is used in earth-moving drilling, flushing wellbore, wellbore/well components, etc., to facilitate installation and disassembly, ensure safety, and improve separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

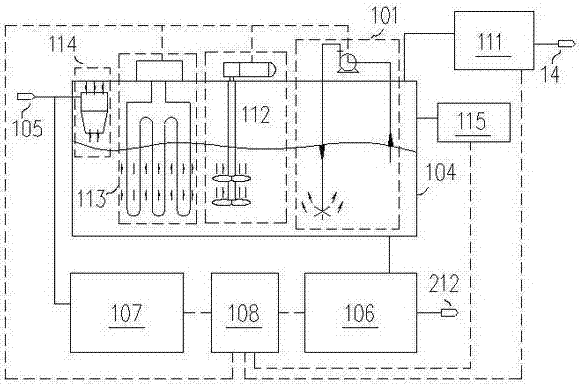

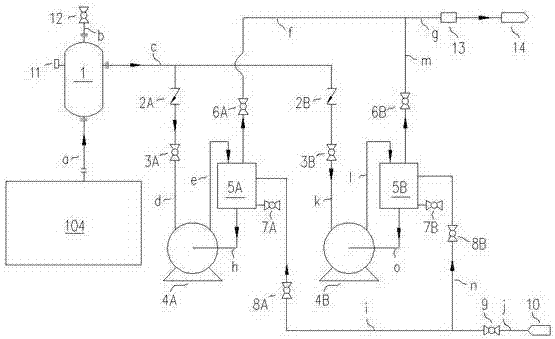

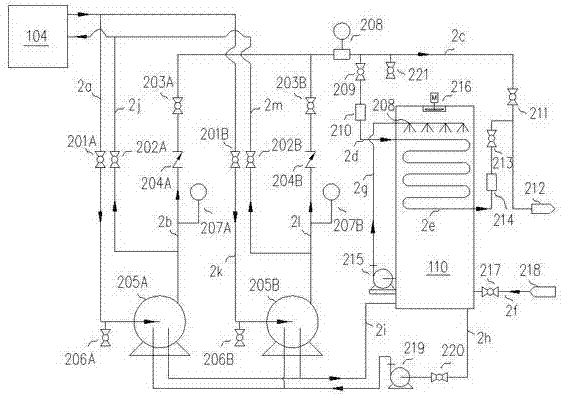

[0032] As a preferred embodiment of the present invention, with reference to the attached Figure 1-7 , this example discloses:

[0033]The drilling fluid hydrogen sulfide removal system is characterized in that it includes: a system inlet, a high-speed cyclone, a heating system, a stirring mechanism, an injection mechanism, a separation tank, a vacuum system, and a data monitoring and acquisition system. The system inlet and the high-speed cyclone The high-speed cyclone is connected to the heating system, the heating system is connected to the stirring mechanism, the stirring mechanism is connected to the spraying mechanism, and the high-speed cyclone, the heating system, the stirring mechanism and the spraying mechanism are arranged in The inside of the separation tank, the separation tank is connected with the vacuum system, the drilling fluid hydrogen sulfide removal system also includes: desulfurization agent injection system, centralized control system and liquid drainag...

Embodiment 2

[0035] As another preferred embodiment of the present invention, with reference to the attached Figure 1-7 , this example discloses:

[0036] The drilling fluid hydrogen sulfide removal system is characterized in that it includes: a system inlet, a high-speed cyclone, a heating system, a stirring mechanism, an injection mechanism, a separation tank, a vacuum system, and a data monitoring and acquisition system. The system inlet and the high-speed cyclone The high-speed cyclone is connected to the heating system, the heating system is connected to the stirring mechanism, the stirring mechanism is connected to the spraying mechanism, and the high-speed cyclone, the heating system, the stirring mechanism and the spraying mechanism are arranged in The inside of the separation tank, the separation tank is connected with the vacuum system, the drilling fluid hydrogen sulfide removal system also includes: desulfurization agent injection system, centralized control system and liquid ...

Embodiment 3

[0040] As another preferred embodiment of the present invention, with reference to the attached Figure 1-7 , this example discloses:

[0041] The drilling fluid hydrogen sulfide removal system is characterized in that it includes: a system inlet, a high-speed cyclone, a heating system, a stirring mechanism, an injection mechanism, a separation tank, a vacuum system, and a data monitoring and acquisition system. The system inlet and the high-speed cyclone The high-speed cyclone is connected to the heating system, the heating system is connected to the stirring mechanism, the stirring mechanism is connected to the spraying mechanism, and the high-speed cyclone, the heating system, the stirring mechanism and the spraying mechanism are arranged in The inside of the separation tank, the separation tank is connected with the vacuum system, the drilling fluid hydrogen sulfide removal system also includes: desulfurization agent injection system, centralized control system and liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com