Emission-free production technology for sulfonate additive

A technology of sulfonate and production process, which is applied in the field of non-emission production process of sulfonate additives, can solve the problems of waste gas and wastewater discharge polluting the environment, wasting resources, etc., and achieve the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

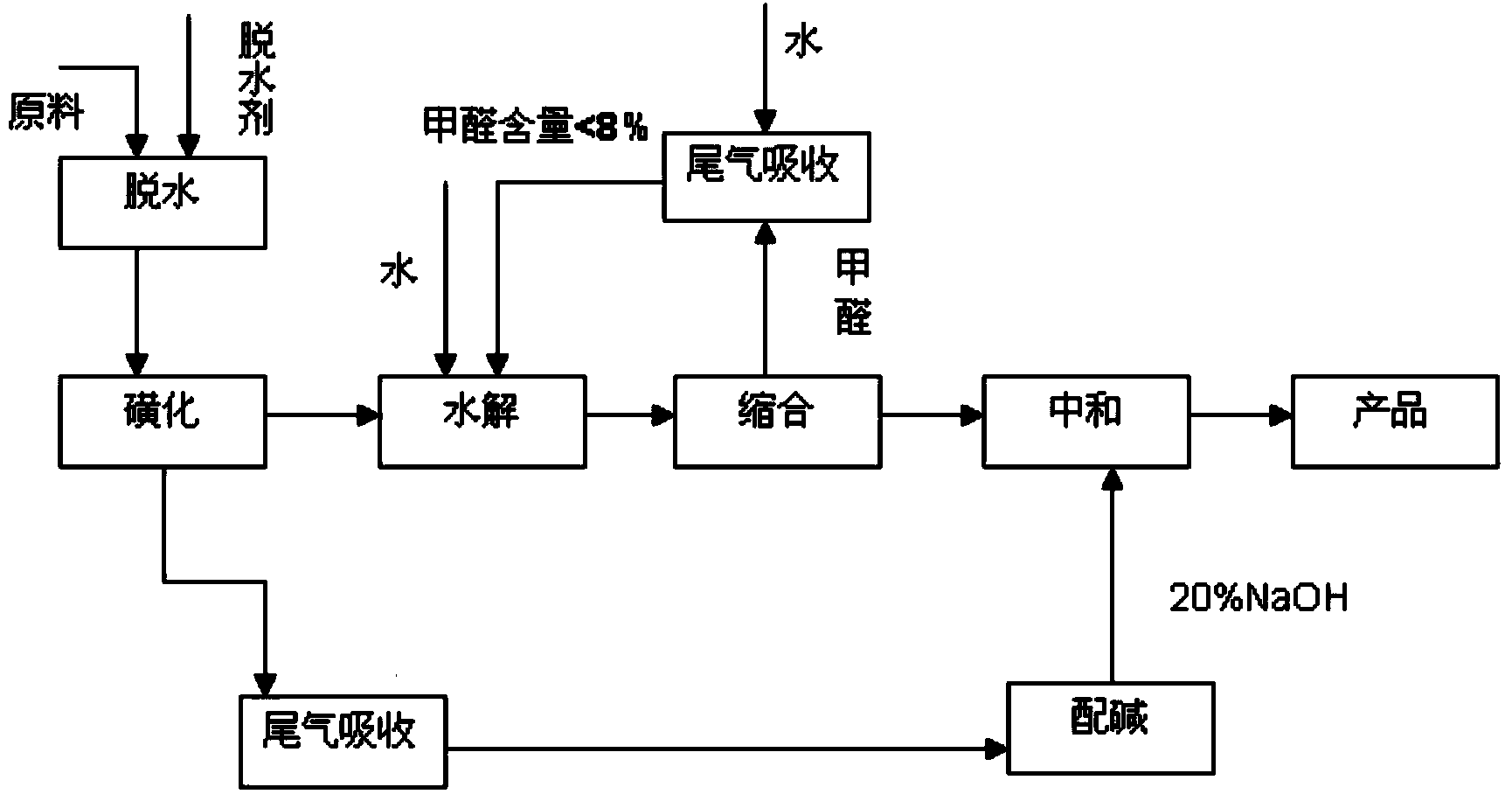

Method used

Image

Examples

Embodiment 1

[0022] This example relates to anthracene-based sulfonate additives with anthracene oil (specifically, mono-anthracene oil) as the main raw material. The specific process conditions are as follows:

[0023] (1) Sulfonation: Add 2300kg of measured anthracene oil into reactor A to preheat to 110°C at room temperature, add quantitative 98% concentrated sulfuric acid 2000kg into reactor A through a flow meter, and control the dropping process at 0.5 h, and then raise the temperature of reactor A to 125° C., and keep the temperature for 1.5 h.

[0024] The sulfur dioxide gas generated during the reaction process is sprayed and absorbed in the acid gas absorption tower with a 10% sodium hydroxide solution. The waste lye obtained after absorption is firstly titrated with potassium hydrogen phthalate to a concentration of 5% sodium hydroxide solution, and then the waste lye is reused in the alkali mixing tank, and the liquid alkali and tap water with a mass fraction of 32% are calcula...

Embodiment 2

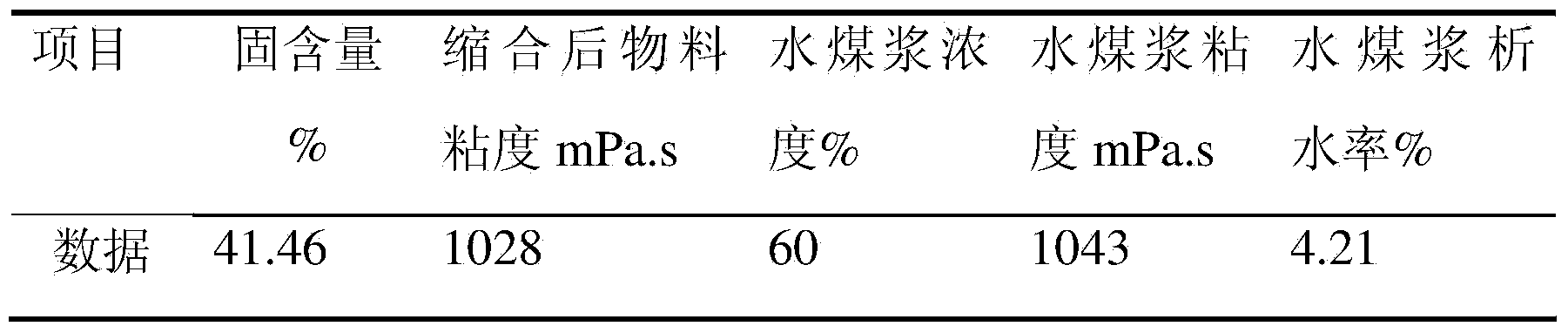

[0034] Blank test: no formaldehyde is contained in the hydrolyzed dilution water, 20wt.%NaOH solution is completely prepared with tap water, and the slurrying performance evaluation results of the prepared additive product are as follows:

[0035]

Embodiment 3

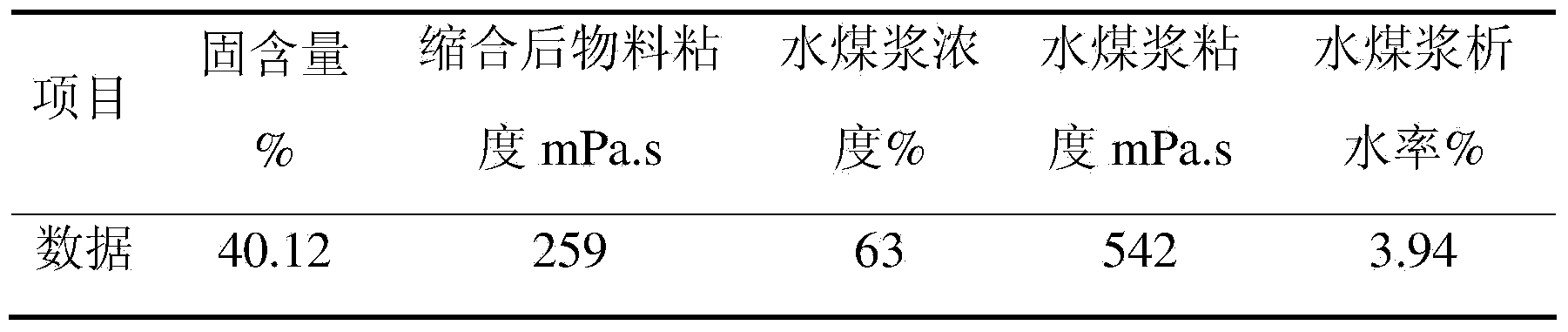

[0037] The formaldehyde content in hydrolyzed dilution water is 0.5%, and 20% NaOH solution is prepared with tap water, and the slurrying performance evaluation results of the prepared additive product are as follows:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com