Microbial deodorizer and preparation method and usage thereof

A technology of microorganisms and deodorants, which is applied in the field of microbial deodorants, can solve the problems of not eliminating odorous substances from the source, toxicity, and treating the symptoms but not the root cause, so as to solve the problem of incomplete deodorization, inhibit release, and promote the growth of beneficial microorganisms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

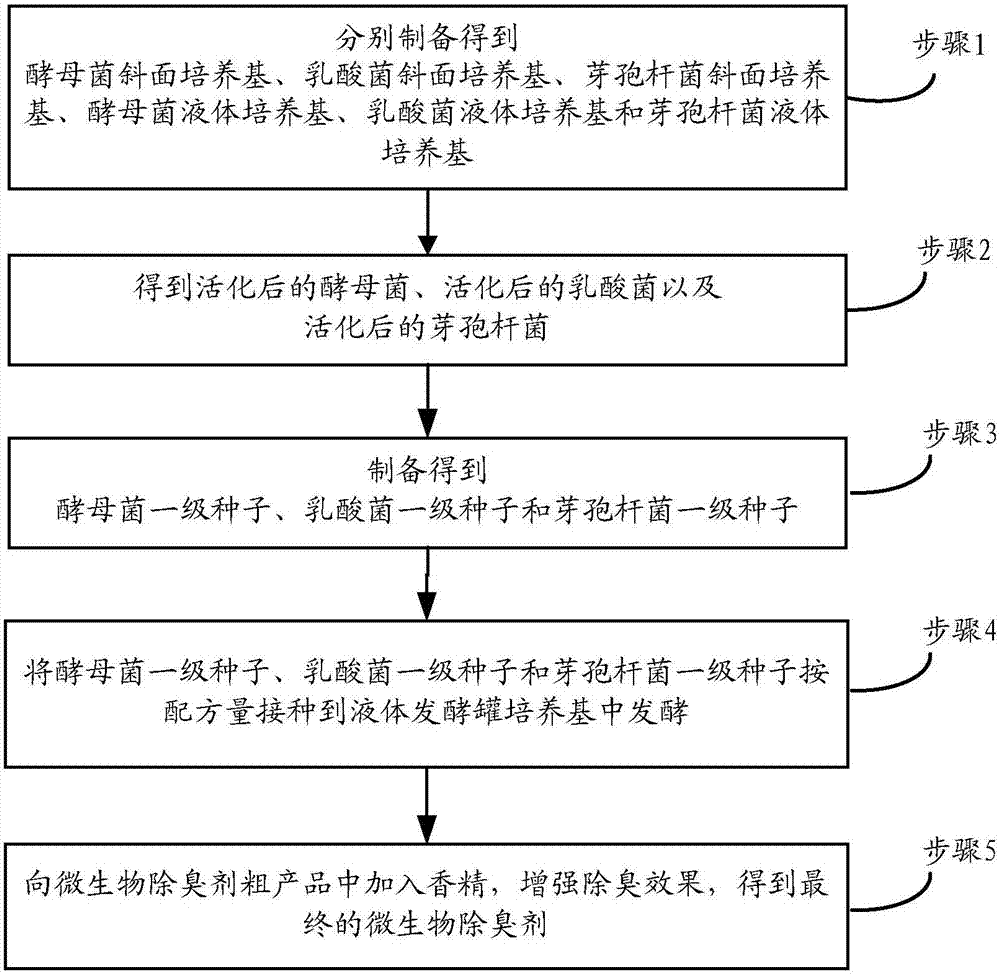

[0042] The preparation method of microbial deodorant comprises the following steps:

[0043] Step 1, respectively preparing yeast slant medium, lactic acid bacteria slant medium, bacillus slant medium, yeast liquid medium, lactic acid bacteria liquid medium and bacillus liquid medium;

[0044] Wherein, the composition of the yeast slant medium is: 4.0% by mass fraction of brown sugar, 1.0% by mass fraction of corn steep liquor, 0.5% by mass fraction of peptone, 1.0% by mass fraction of sodium chloride, and the rest is water;

[0045] The composition of the yeast liquid culture medium is: 8.0% mass fraction of molasses, 1.0% mass fraction of corn steep liquor, 0.5% mass fraction of ammonium sulfate, 0.2% mass fraction of potassium dihydrogen phosphate, and 0.1% mass fraction of magnesium sulfate , 0.1% mass fraction of sodium chloride, the rest is water; pH 6.5, tank pressure 0.07-0.08MPa, speed 130r / min;

[0046] The composition of described lactic acid bacteria slant culture...

Embodiment 1

[0067] Step 1, inoculate the yeast on the yeast slant medium, and activate it at 35°C for 20 hours to obtain the activated yeast;

[0068] Inoculate lactic acid bacteria on a lactic acid bacteria slant medium, and activate them at 35°C for 18 hours to obtain activated lactic acid bacteria;

[0069] Inoculate the bacillus on the bacillus slant medium, and activate it at 35°C for 18 hours to obtain the activated bacillus;

[0070] Step 2, inoculating the activated yeast in the yeast liquid medium, culturing at 30°C for 24 hours until the seeds mature, and preparing first-grade yeast seeds;

[0071] Inoculating the activated lactic acid bacteria into a lactic acid bacteria liquid medium, culturing at 37°C for 24 hours until the seeds mature, and preparing first-grade seeds of lactic acid bacteria;

[0072] inoculating the activated bacillus in the bacillus liquid medium, culturing at 37°C for 24 hours until the seeds mature, and preparing the first-grade bacillus seeds;

[0073...

Embodiment 2

[0076] Step 1, inoculate the yeast on the yeast slant medium, and activate it at 35°C for 20 hours to obtain the activated yeast;

[0077] Inoculate lactic acid bacteria on a lactic acid bacteria slant medium, and activate them at 35°C for 18 hours to obtain activated lactic acid bacteria;

[0078] Inoculate the bacillus on the bacillus slant medium, and activate it at 35°C for 18 hours to obtain the activated bacillus;

[0079] Step 2, inoculating the activated yeast in the yeast liquid medium, culturing at 30°C for 24 hours until the seeds mature, and preparing first-grade yeast seeds;

[0080] Inoculating the activated lactic acid bacteria into a lactic acid bacteria liquid medium, culturing at 37°C for 24 hours until the seeds mature, and preparing first-grade seeds of lactic acid bacteria;

[0081] inoculating the activated bacillus in the bacillus liquid medium, culturing at 37°C for 24 hours until the seeds mature, and preparing the first-grade bacillus seeds;

[0082...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com