The brewing process of tea wine

A process and technology for tea wine, applied in the field of tea wine brewing process, can solve the problems of low nutritional value, astringency, flocculent precipitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

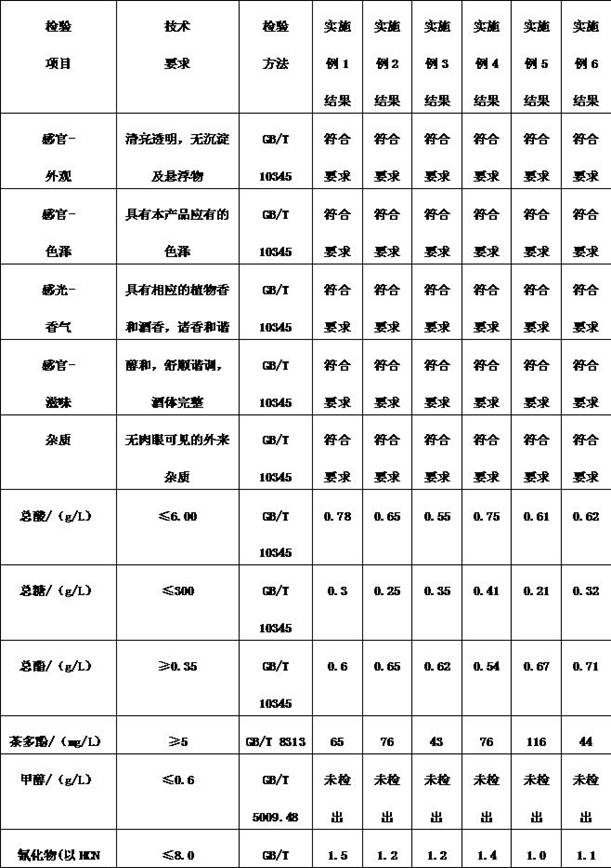

Examples

Embodiment 1

[0024] A brewing process of tea wine, comprising the following steps:

[0025] (1) Prepare raw materials, including the following raw materials in mass percentages: 28% tea, 45% malt, 1.4% koji, and 25.6% water. The tea leaves are white tea.

[0026] (2) Heat the tea leaves in water to 65°C for 20 hours to obtain tea extract.

[0027] (3) The malt is steamed and fermented into juice, then saccharified for 30 hours, and then fermented for 20 hours.

[0028] (4) Monitor the pH value of the tea extract in step (2). When the pH is 6.0, mix and ferment the tea extract and maltosaccharification liquid at a mass ratio of 1:5.

[0029] (5) Put the distiller's yeast into the material that completed the mixed fermentation in step (4) for constant temperature fermentation.

[0030] (6) After the constant temperature fermentation is completed, the acid-base balance is monitored again. When the balance is reached, the slag juice is separated and distilled, then the head is cut off and t...

Embodiment 2

[0032] A brewing process of tea wine, comprising the following steps:

[0033] (1) Prepare raw materials, including the following raw materials in mass percentages: 28% tea, 50% malt, 1.5% koji, and 20.5% water. Described tealeaves is green tea.

[0034] (2) Heat the tea leaves in water to 75°C for 12 hours to obtain tea extracts.

[0035] (3) The malt is steamed and fermented into juice, then saccharified for 25 hours, and then fermented for 15 hours.

[0036] (4) Monitor the pH value of the tea extract in step (2). When the pH is 6.1, mix and ferment the tea extract and maltosaccharification liquid at a mass ratio of 1:6.

[0037] (5) Put the distiller's yeast into the material that completed the mixed fermentation in step (4) for constant temperature fermentation.

[0038] (6) After the constant temperature fermentation is completed, the acid-base balance is monitored again. When the balance is reached, the slag juice is separated and distilled, then the head is cut off ...

Embodiment 3

[0040] A brewing process of tea wine, comprising the following steps:

[0041] (1) Prepare raw materials, including the following raw materials in mass percentage: 30% tea, 49% malt, 1.5% koji, and 19.5% water. The tea leaves are black tea.

[0042] (2) Heat the tea leaves in water to 68°C for 23 hours to obtain tea extract.

[0043] (3) The malt is steamed and fermented into juice, then saccharified for 28 hours, and then fermented for 30 hours.

[0044] (4) Monitor the pH value of the tea extract in step (2). When the pH is 6.03, mix and ferment the tea extract and maltosaccharification liquid at a mass ratio of 1:5.5.

[0045] (5) Put the distiller's yeast into the material that completed the mixed fermentation in step (4) for constant temperature fermentation.

[0046] (6) After the constant temperature fermentation is completed, the acid-base balance is monitored again. When the balance is reached, the slag juice is separated and distilled, then the head is cut off and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com