Production method of macromolecular chelating agent for treating heavy metal ions in wastewater

A polymer chelating agent, heavy metal ion technology, applied in chemical instruments and methods, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. The problem of high cost is to achieve the effect of good flocculation and sedimentation, lower reaction temperature and lower energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

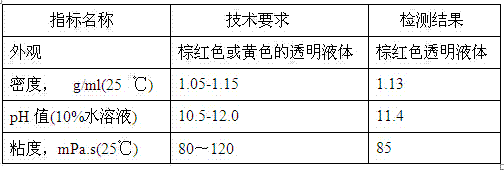

Embodiment 1

[0057] Embodiment 1 A kind of production method that can be used for removing the polymer chelating agent of multiple heavy metal ions in waste water

[0058] The synthesis reaction of the polymer chelating agent is carried out in a 1500L enamel kettle.

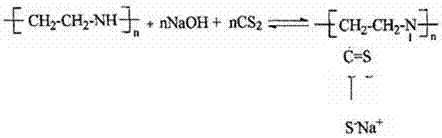

[0059] The polymer chelating agent is polyethylenimine dithiocarbamate.

[0060] (1) Carbon disulfide high tank feeding

[0061] Use compressed air to press 98.5kg (1296mol) carbon disulfide from the storage tank to the carbon disulfide high level tank, and keep the height of the upper water layer of the carbon disulfide high level tank at 10-15mm.

[0062] (2) Synthetic kettle feeding

[0063] 630kg (35000mol) of deionized water, 190kg of industrial NaOH (the molar number of NaOH is 1425mol) solution with a mass concentration of 30% (the molar number of NaOH is 1425mol) was sequentially pumped into the synthesis kettle by vacuum, and 0.08kg of 4-dimethylaminopyridine (DMAP), 0.12kg1 -(3-Dimethylaminopropyl)-3-ethylcarbodi...

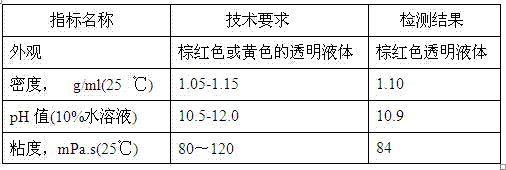

Embodiment 2

[0081] Embodiment 2 A kind of production method that can be used for removing the polymer chelating agent of multiple heavy metal ions in waste water

[0082] The synthesis reaction of the polymer chelating agent is carried out in a 1500L enamel kettle.

[0083] The polymer chelating agent is polyethylenimine dithiocarbamate.

[0084] (1) Carbon disulfide high tank feeding

[0085] Use compressed air to press 99.5kg (1309mol) carbon disulfide from the storage tank to the carbon disulfide header tank, and keep the height of the water layer at the upper part of the carbon disulfide header tank at 10-15mm.

[0086] (2) Synthetic kettle feeding

[0087] 640kg (35555mol) of deionized water, 200kg of industrial NaOH with a mass concentration of 30% (the molar number of NaOH is 1500mol) was sequentially pumped into the synthesis kettle by vacuum, and 0.10kg of 4-dimethylaminopyridine (DMAP), 0.14kg1 -(3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), start stirring, ...

Embodiment 3

[0103] Embodiment 3 A kind of production method that can be used for removing the polymer chelating agent of multiple heavy metal ions in waste water

[0104] The synthesis reaction of the polymer chelating agent is carried out in a 1500L enamel kettle.

[0105] The polymer chelating agent is polyethylenimine dithiocarbamate.

[0106] (1) Carbon disulfide high tank feeding

[0107] Use compressed air to press 100kg (1316mol) carbon disulfide from the storage tank to the carbon disulfide header tank, and keep the height of the water layer at the upper part of the carbon disulfide header tank at 10-15mm.

[0108] (2) Synthetic kettle feeding

[0109] 650kg (36111mol) of deionized water, 210kg of industrial NaOH with a mass concentration of 30% (the molar number of NaOH is 1575mol) were sequentially pumped into the synthesis kettle by vacuum, and 0.12kg of 4-dimethylaminopyridine (DMAP), 0.16kg1 -(3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), start stirring, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com