Polycyclic carbonate resin, preparation method thereof at normal pressure and application thereof

A carbonate resin and multi-ring technology, applied in the field of multi-ring carbonate resin and its preparation under normal pressure, can solve the problems of rising production cost, high equipment requirements, poor coating film performance, etc., avoiding high temperature and high pressure and equipment requirements. Low, short response time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) prepare chlorohydrin resin:

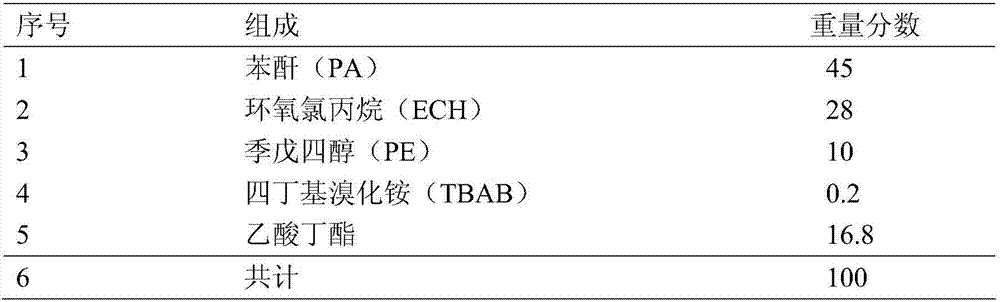

[0038] formula:

[0039] Table 1a

[0040]

[0041] Preparation method: Add metered phthalic anhydride, polyol pentaerythritol and solvent butyl acetate into a four-neck flask equipped with a thermometer, condenser, stirring paddle and constant pressure funnel, raise the temperature to 110°C, keep it warm for 4 hours, add catalyst tetrabutyl bromide ammonium chloride and start to add epichlorohydrin dropwise, keep warm for 6 hours, after the acid value of the resin is less than 15mgKOH / g, remove the solvent and then cool down and discharge the material.

[0042] Chlorohydrin resin properties: colorless transparent liquid; acid value: 10.78mgKOH / g; solid content: 85.77%, viscosity: 8600mPa·s.

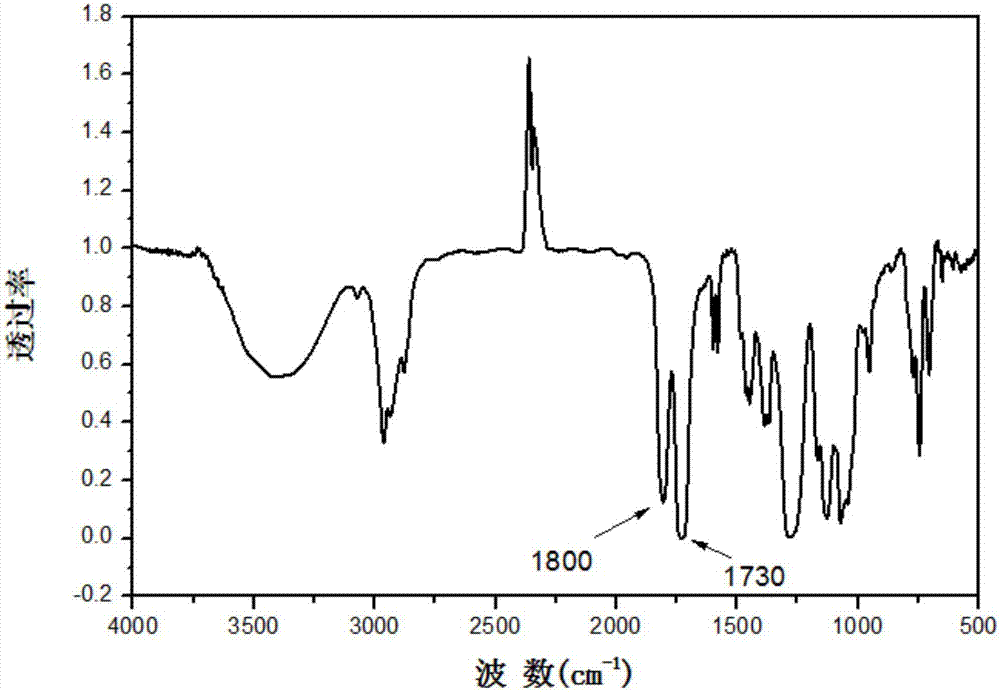

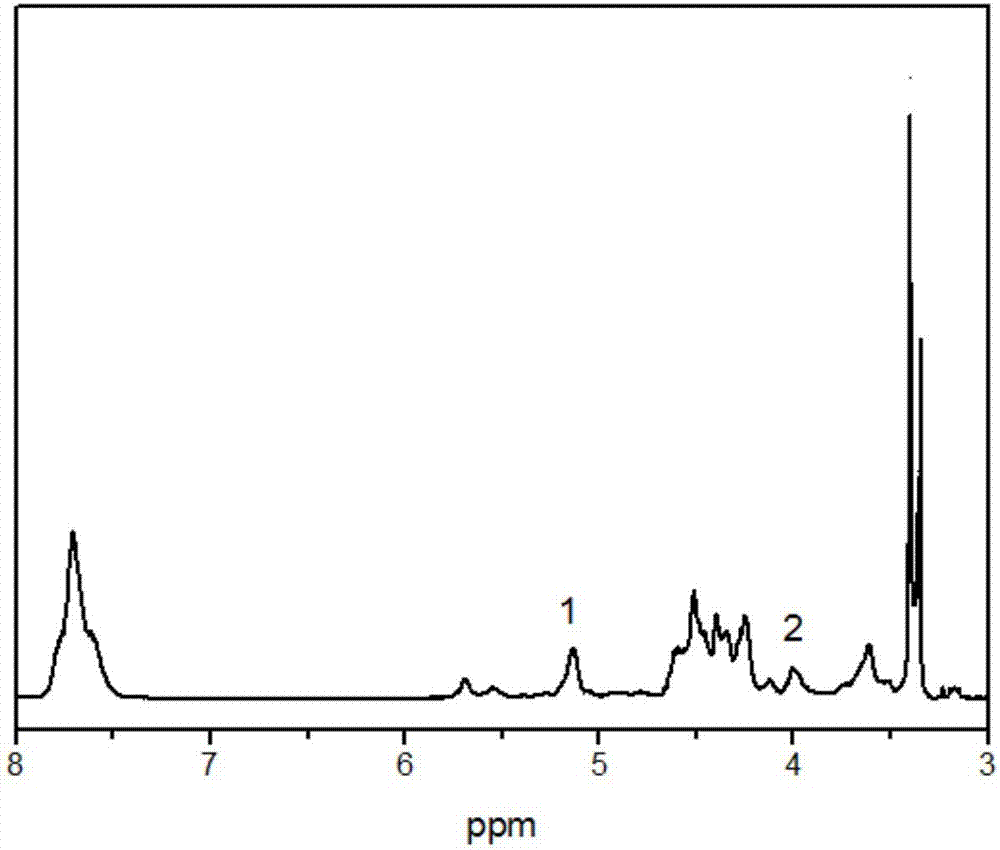

[0043] (2) Preparation of polycyclic carbonate resin resin

[0044] formula:

[0045] Table 1b

[0046]

[0047] Preparation method: In a four-necked flask equipped with a thermometer and a stirring paddle, add metered amounts of the ab...

Embodiment 2

[0058] (1) prepare chlorohydrin resin:

[0059] formula:

[0060] Table 2a

[0061]

[0062] Preparation method: Add metered pyromellitic anhydride, glycol 1,4-butanediol and solvent dimethylformamide into a four-neck flask equipped with a thermometer, a condenser tube, a stirring paddle and a constant pressure funnel, and rise to 90°C, keep warm for 5h, add catalyst tetraethylammonium bromide and start to add epichlorohydrin dropwise, keep warm for 7h, after the acid value of the resin is less than 15mgKOH / g, remove the solvent and then cool down and discharge.

[0063] Chlorohydrin resin properties: orange-yellow transparent liquid; acid value: 13.08mgKOH / g; solid content: 76.88%, viscosity: 1596mPa·s;

[0064] (2) Preparation of polycyclic carbonate resin resin

[0065] formula:

[0066] Table 2b

[0067]

[0068] Preparation method: In a four-necked flask equipped with a thermometer and a stirring paddle, add metered amounts of the above-mentioned synthesized ch...

Embodiment 3

[0071] (1) prepare chlorohydrin resin:

[0072] formula:

[0073] Table 3a

[0074]

[0075] Preparation method: add measured amounts of trimellitic anhydride, polyol pentaerythritol and solvent dimethylformamide into a four-neck flask equipped with a thermometer, condenser, stirring paddle and constant pressure funnel, raise the temperature to 100°C, keep it warm for 5 hours, add catalyst tetrabutyl Base ammonium bromide and start to drop epichlorohydrin, keep it warm for 8 hours, after the acid value of the resin is less than 15mgKOH / g, remove the solvent and then cool down and discharge.

[0076] Chlorohydrin resin properties: wine red transparent liquid; acid value: 11.58mgKOH / g; solid content: 60.80%, viscosity: 622mPa s;

[0077] (2) Preparation of polycyclic carbonate resin resin

[0078] formula:

[0079] Table 3b

[0080]

[0081] Preparation method: In a four-neck flask equipped with a thermometer and a stirring paddle, add the metered amount of the above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com