Hot-air temperature increasing and humidity reducing device for greenhouse

A greenhouse and hot air technology, applied in greenhouse cultivation, application, climate change adaptation, etc., can solve the problems of affecting crop growth, overheating of the air outlet, prone to high temperature, etc., to reduce air humidity, avoid high temperature and high pressure, and uniform temperature distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

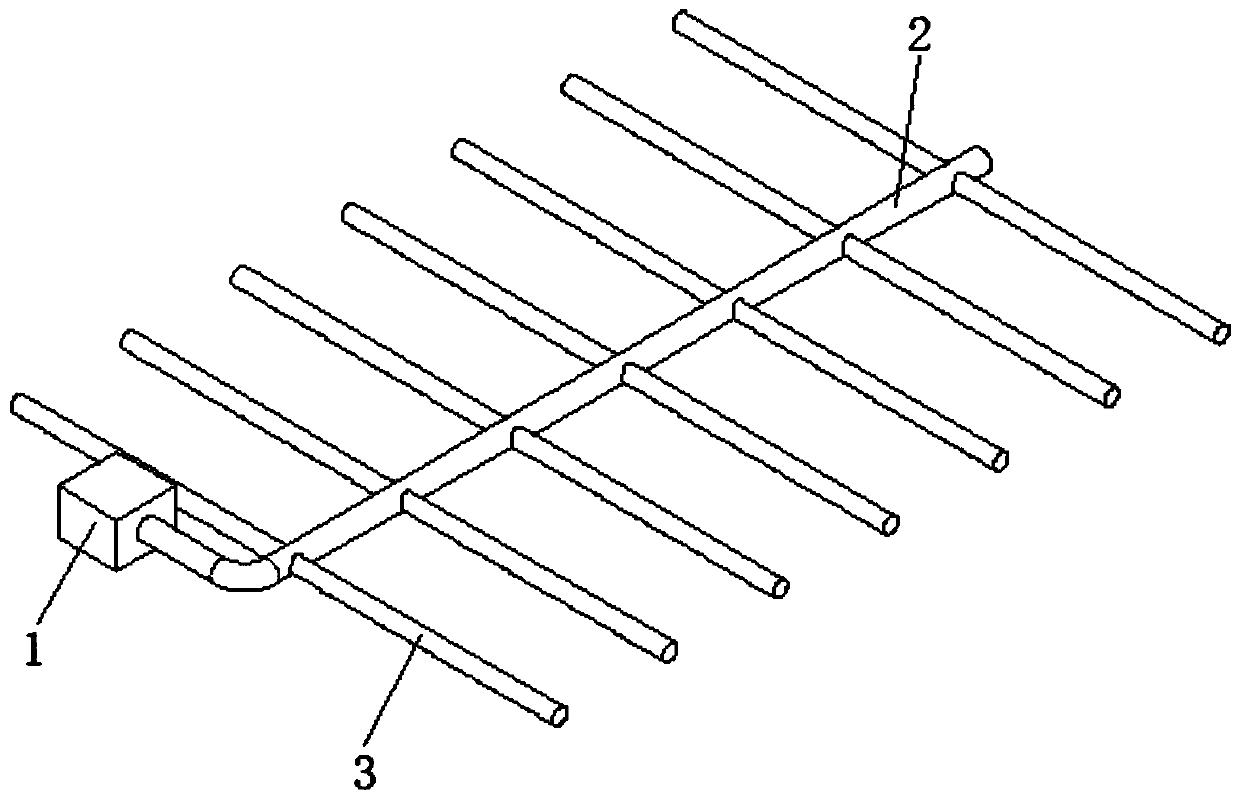

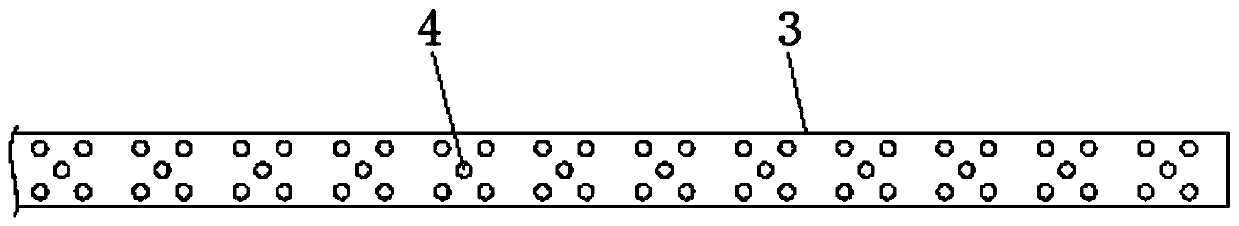

[0023] see figure 1 , figure 2 and Figure 4 As shown, the present invention is a hot air temperature increasing and dehumidifying device for a greenhouse, comprising a heater 1, a main pipe 2 connected to the air outlet of the heater 1, a branch pipe 3 connected to the main pipe 2, and the surface of the branch pipe 3 is provided with a The grid-shaped exhaust holes 4 are evenly distributed in the axial direction.

[0024] Wherein, the branch pipes 3 are arranged in parallel at equidistant intervals along the axial direction of the main pipe 2 , and the branch pipes 3 are symmetrically distributed on both sides of the main pipe 2 .

[0025] The technical parameters of the hot air heating and dehumidification device are calculated and designed as follows:

[0026] 1. Estimation of the maximum heating load

[0027] The size of the heating load is constantly changing with the outdoor temperature. The supplementary heat required to maintain the normal growth of crops in the...

Embodiment 2

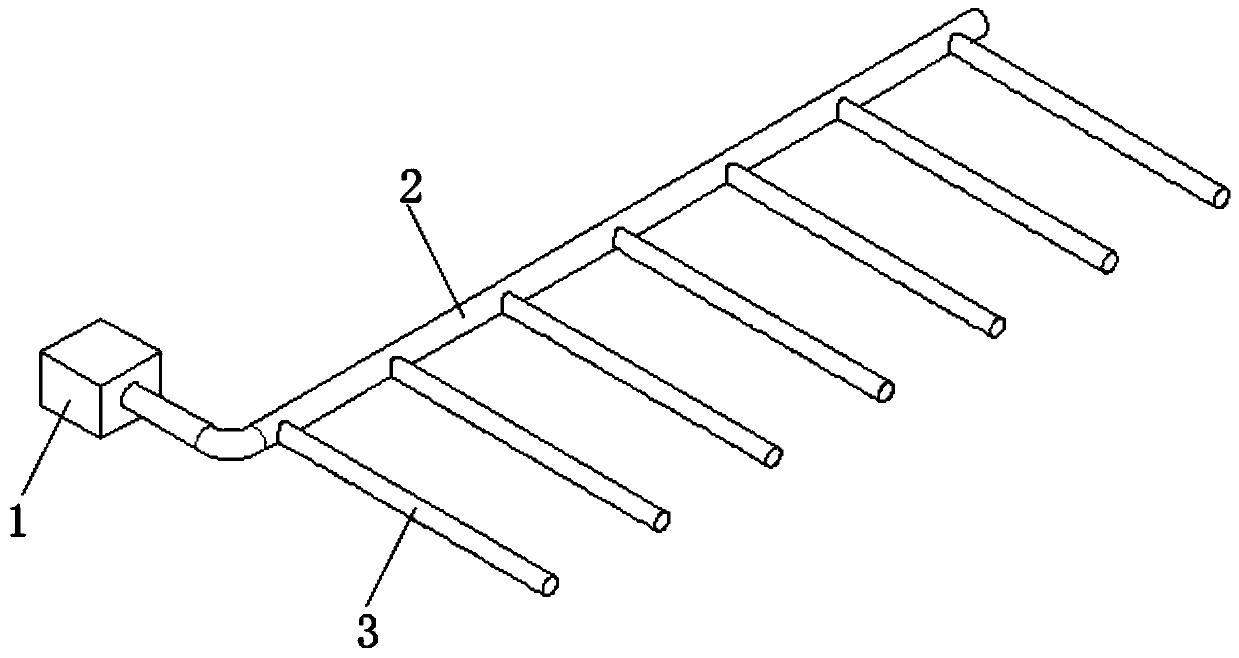

[0090] see image 3 As shown, compared with Embodiment 1, this embodiment only changes the distribution position of the branch pipe 3, so that the branch pipe 3 is distributed on one side of the main pipeline 2, and correspondingly changes the number and length of the branch pipe: the length of the branch pipe 3 is 8 meters , the quantity is 16 pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com