A kind of preparation method of modified ultrafine precious metal powder

A precious metal and powder technology, applied in the field of preparation of modified ultrafine precious metal powder, to achieve the effect of improving tap density, changing tap density, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

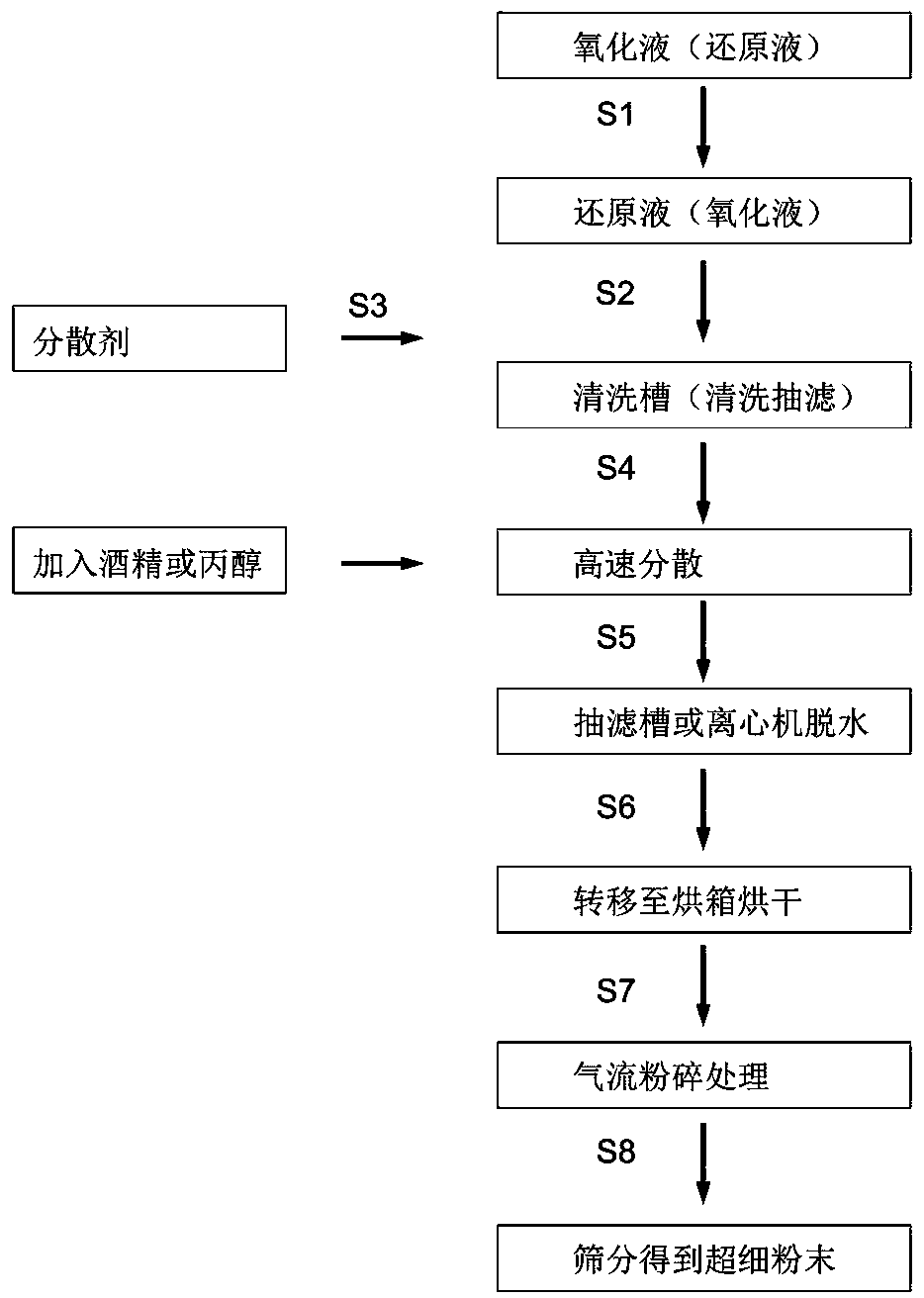

[0024] Such as figure 1 As shown in the flowchart, the preparation method mainly includes steps from the generalized technical scheme: 1. Prepare the reducing solution, weigh the reducing agent and dissolve it in deionized water, and keep the concentration of the reducing agent in the reducing solution at 0.05 mol / liter to 9 mol / L, fully stir until the reducing agent is completely dissolved, then add additives and protective agents to continue fully stirring and maintain a constant temperature state, the constant temperature range is between 15°C and 85°C; prepare the oxidation solution, and weigh the nitrate and chloric acid of precious metals Dissolve the salt or sulfate solid in deionized water, keep the concentration of noble metal ions in the oxidizing solution at 0.05 mol / L~9 mol / L, stir well until the solid is completely dissolved, then add additives and protective agents to continue fully stirring and maintain a constant temperature , the constant temperature range is ...

Embodiment 1

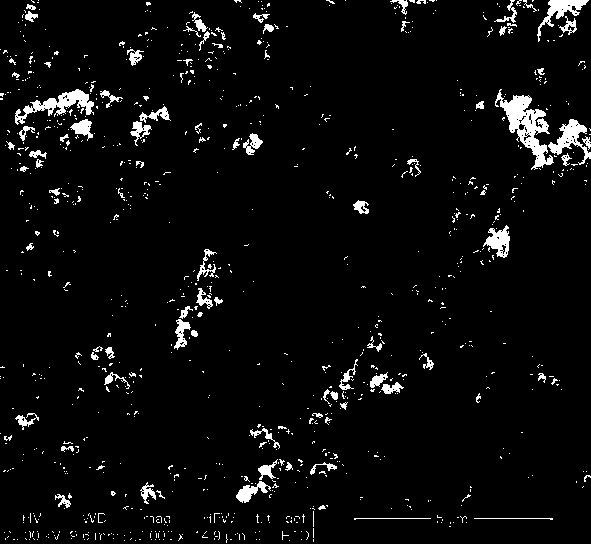

[0028] Embodiment 1, take by weighing 5kg silver nitrate and be dissolved in 55L deionized water, treat to dissolve completely, then quantitatively add 2.8L32% sodium hydroxide in its solution, flow rate is 0.5L / minute, and reaction generates silver oxide, at this moment It acts as an oxidizing fluid. Measure 0.9 liter of 50% hydrazine hydrate, and then add 50 g of triethanolamine to its solution to prepare a reducing solution. Quantitatively pump the prepared reducing solution into the oxidizing solution, and control the flow rate at 0.15 L / min. After the reaction is complete, add an ester dispersant to the reaction solution, stir rapidly for 20 minutes, and then discharge, clean and suction filter , and finally disperse with alcohol for the second time, and then send it to an oven for drying. The drying temperature is controlled at 60°C. The dried powder is then crushed by airflow. The pressure of airflow crushing is 1.0MPa, and microcrystalline ultrafine silver powder is ...

Embodiment 2

[0029] Example 2. Weigh 5 kg of glucose and dissolve it in 57.5 L of deionized water. After it is completely dissolved, add 10 L of 30% sodium hydroxide and 5 g of copper nitrate to the solution, and control the temperature of the solution at 15° C. to prepare a reducing solution. Weigh 5 kg of silver nitrate and dissolve it in 80 L of deionized water, wait until it is completely dissolved, then add 100 g of polyvinylpyrrolidone PVP to the solution, control the temperature of the solution at 15°C, and prepare an oxidation solution. Quickly pump the prepared oxidizing solution into the reducing solution, and control the flow rate at 60L / min. After the reaction is complete, add an ester dispersant to the reaction solution, stir rapidly for 20 minutes, and then clean and filter with suction, and finally use Wash it with alcohol, drain it and send it to an oven for drying. The drying temperature is controlled at 60°C. The dried powder is then crushed by airflow, and the pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com