Lamp manufacturing robot

A technology for robots and lamps, applied in the field of lamps and lanterns manufacturing robots, can solve the problems of low degree of automation and the use of labor, and achieve the effect of reducing production costs and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

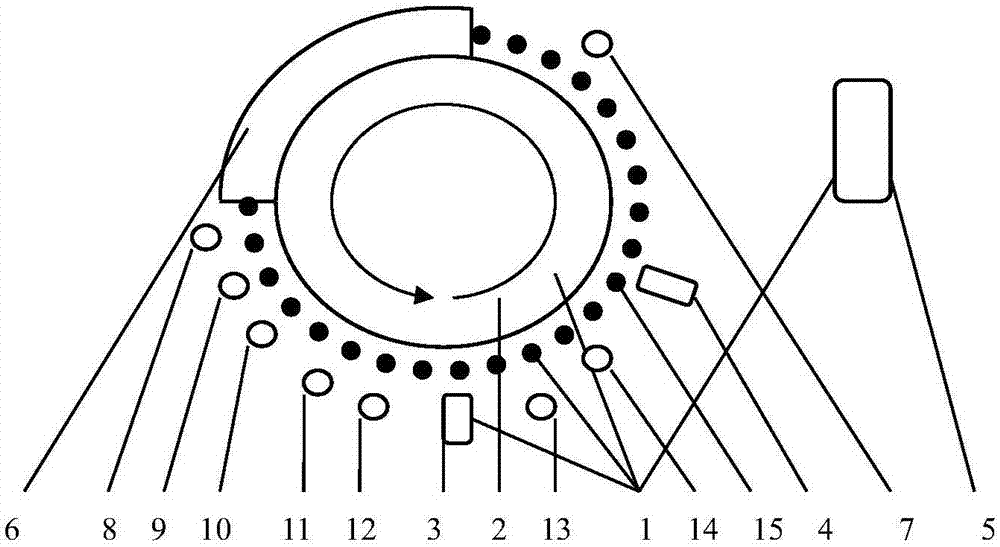

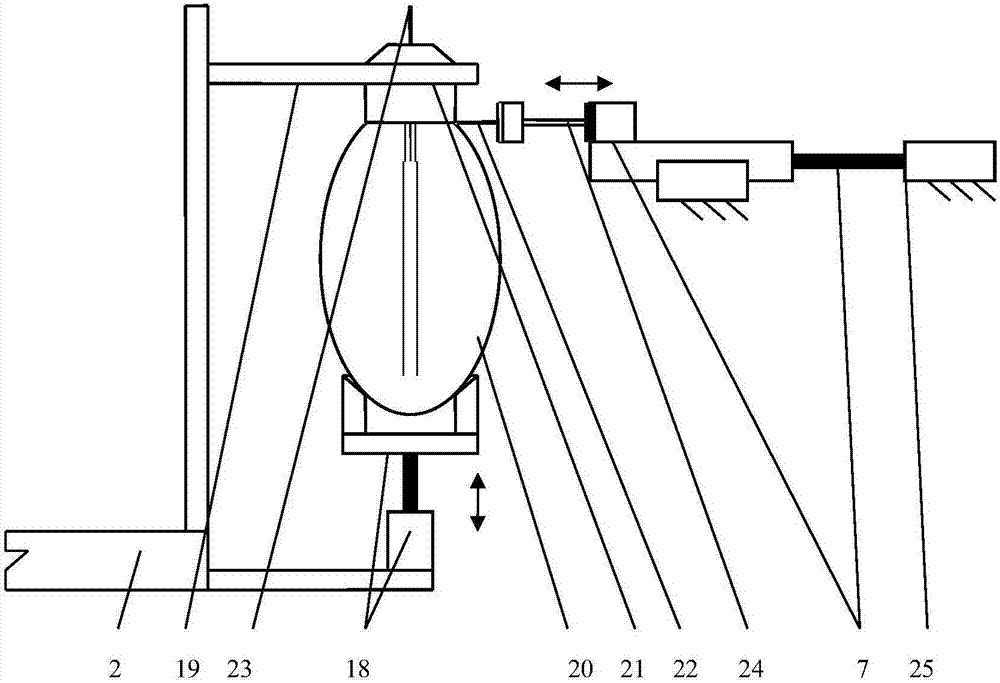

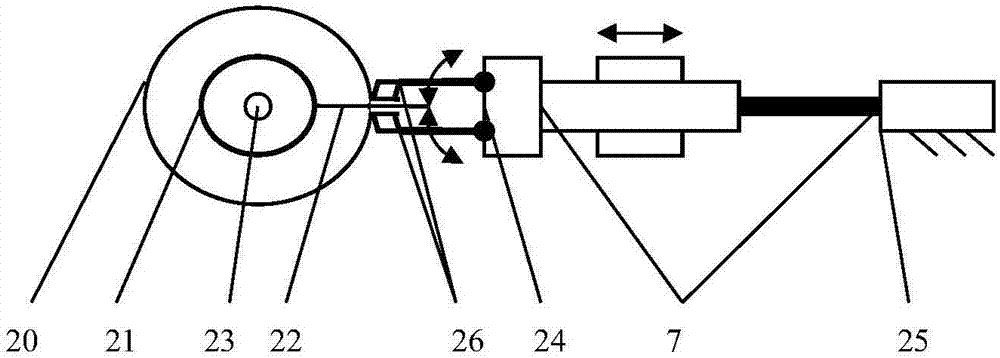

[0040] Embodiment 1, manufacturing a lamp manufacturing robot 1, including the main rotating platform 2, the side wire automatic welding mechanism 3 arranged on the periphery of the main rotating platform 2, the top wire automatic welding mechanism 4, the side wire welding pre-processing facilities, the top wire welding Pre-processing facility and control system 5; the pre-processing facility for edge wire welding includes a wire pulling mechanism 7 arranged in front of the drying tunnel 6, and a wire pulling mechanism 8, a vertical wire mechanism 9, and an edge trimming mechanism 10 arranged in sequence behind the drying tunnel 6 1. Bending wire mechanism 11 and crimping wire mechanism 12; pre-treatment facilities for top wire welding include top wire cutting mechanism 13 and top wire mechanism 14; wire pulling mechanism 7, wire lifting mechanism 8, vertical wire mechanism 9, edge trimming wire mechanism 10. Bending wire mechanism 11 , crimping wire mechanism 12 , edge wire au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com