Oil duct of novel camshaft phase regulator

A phase adjuster and camshaft technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of high manufacturing cost, rotor holes, low processing efficiency, etc., achieve good consistency, improve work efficiency, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

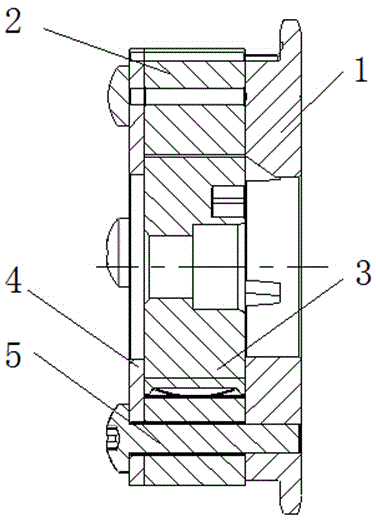

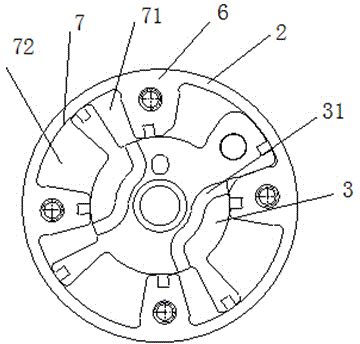

[0017] Such as figure 1 and figure 2 As shown, a novel camshaft phase adjuster oil channel of the present invention includes a sprocket 1, a stator 2, a rotor 3 and a rear cover 4, the rear end of the sprocket 1 is connected with the stator 2, and the rear end of the stator 2 is connected with the rear cover 4. The cavity formed by the sprocket 1, the stator 2 and the rear cover 4 is provided with a rotor 3, and the rear cover 4, the stator 2 and the sprocket 1 are fixed by screws 5, and the inner periphery of the stator 2 is provided with a screw 5 to pass through. The special-shaped end 6 of the special-shaped end 6 forms a special-shaped cavity 7 between two adjacent special-shaped ends 6. The outer periphery of the rotor 3 is provided with a special-shaped claw 8 that is placed in the special-shaped cavity 7 and fits the inner wall of the special-shaped cavity 7. The special-shaped claw 8 will The special-shaped cavity 7 is divided into an advanced angle cavity 71 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com